Wastewater adsorption device and method based on biomass charcoal treatment

A technology of biomass charcoal and adsorption device, which is applied in filtration treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of large labor time, low work efficiency, and reduced oil scraping amount, and achieves easy movement reset. , strong adsorption effect, easy to collect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

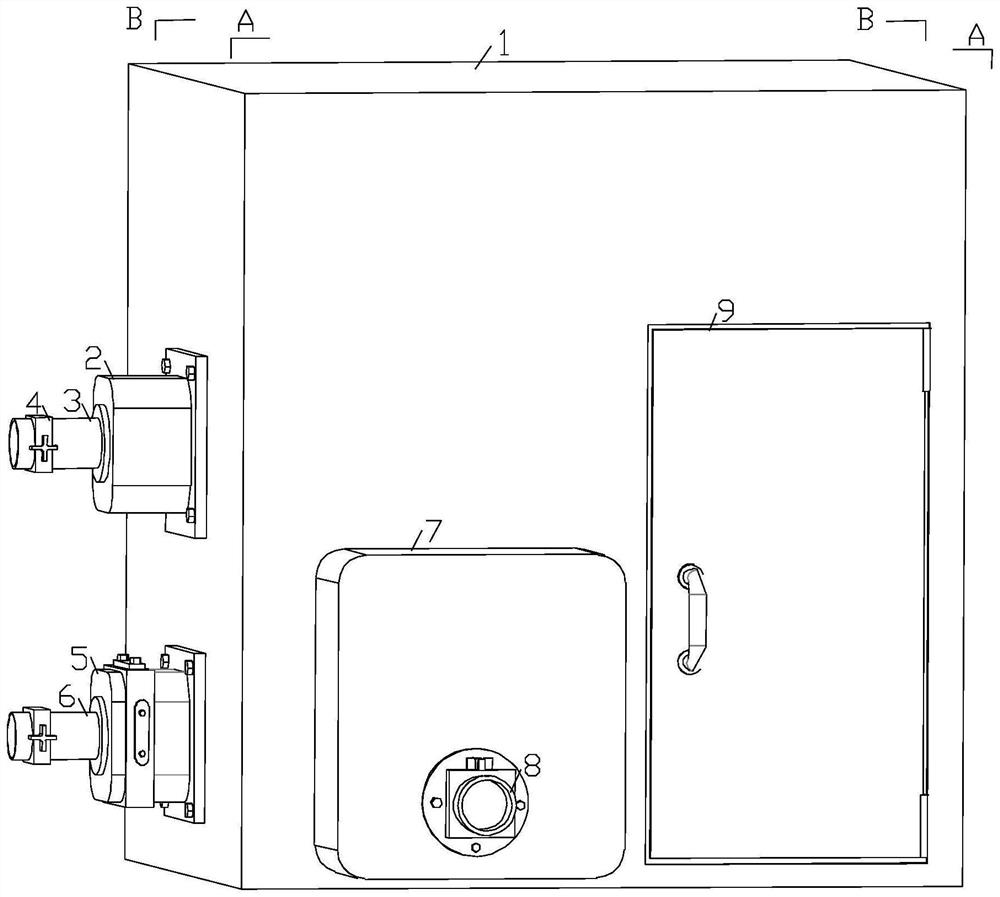

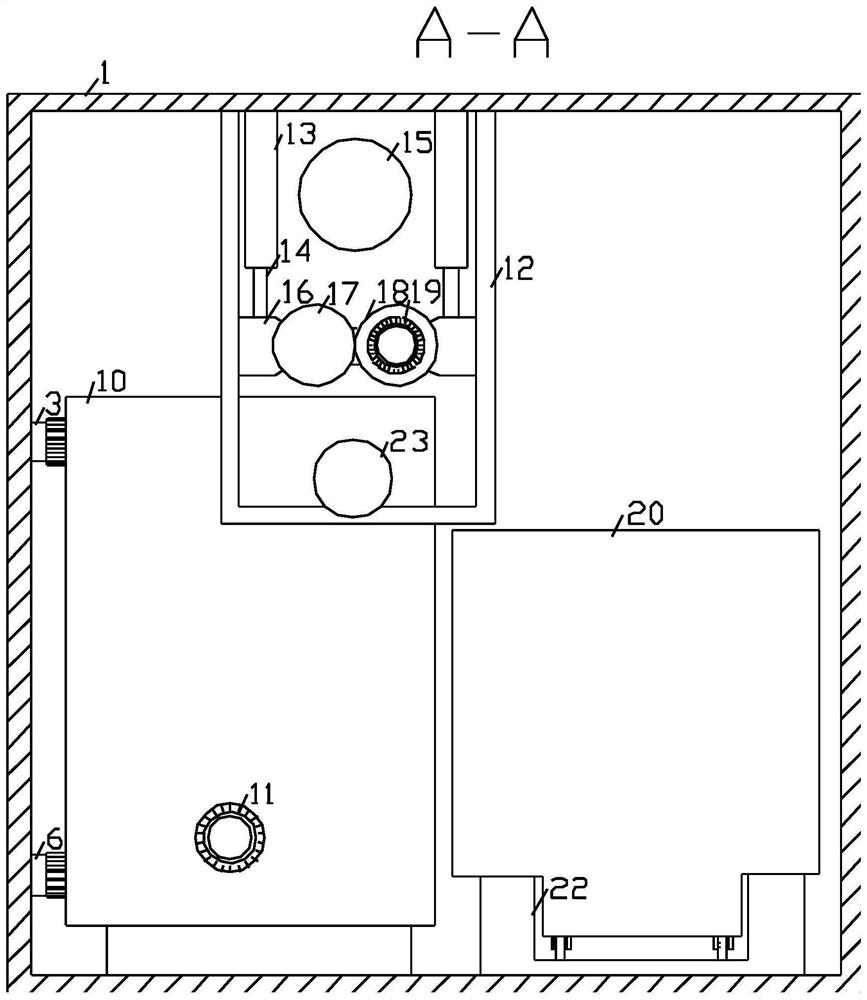

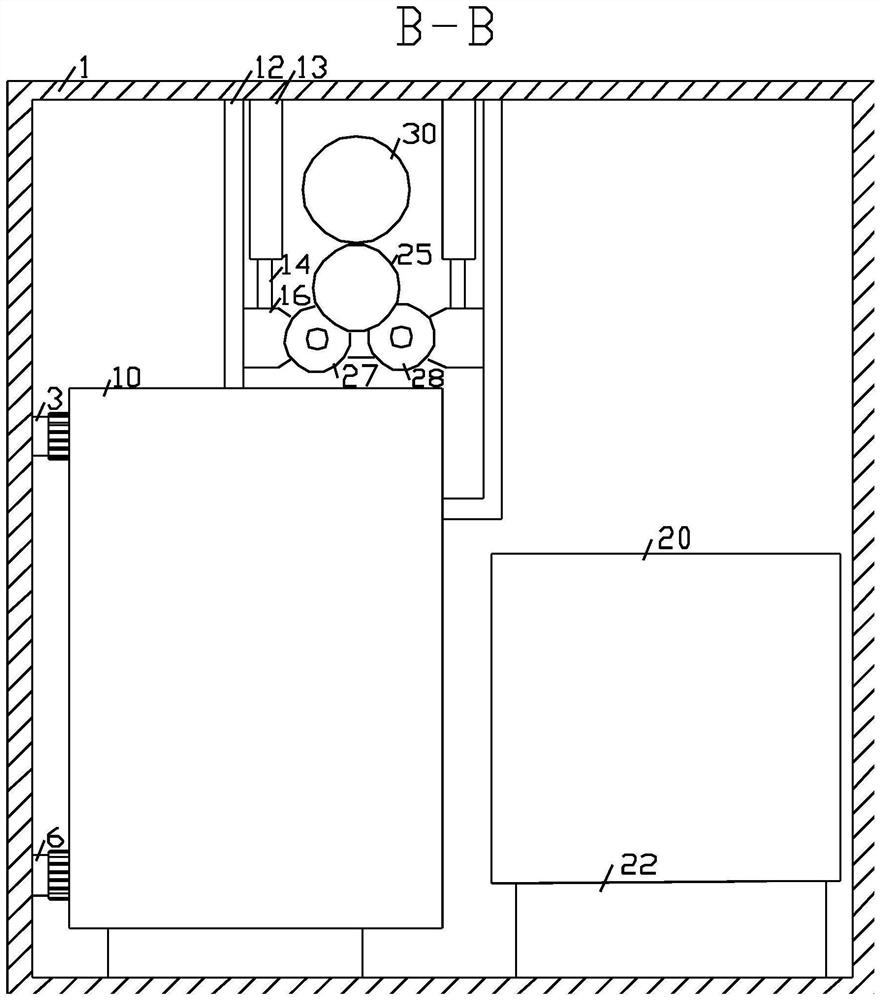

[0037] Embodiment 1 of the present application provides a wastewater adsorption device based on biomass charcoal treatment, including: a device box 1, such as figure 1 As shown, the liquid storage tank 10 is fixedly installed inside the device box 1; the drug filling box 2 is fixedly installed on the upper left side of the device box 1, and the liquid inlet pipe 3 is fixedly installed on the drug adding box 2, and the other end of the liquid inlet pipe 3 is fixed. Connect the liquid storage tank 10; the lower end of the external left side of the device box 1 is fixedly installed with an air pump 5, and the air intake pipe 6 is fixedly installed on the air pump 5, and the other end of the air intake pipe 6 is fixedly connected with the liquid storage tank 10; the upper side of the device box 1 is fixed A device frame 12 is installed, and the device frame 12 is positioned at the upper side of the liquid storage tank 10; the bottom side of the device box 1 on the other side of th...

Embodiment 2

[0042] On the basis of Example 1, Example 2 of the present application provides the working method of the wastewater adsorption device based on biomass charcoal treatment in Example 1:

[0043]When the raw liquid flows through the dosing box 2 from the liquid inlet pipe 3, a reaction agent that promotes oil-liquid separation is added to the raw liquid through the dosing box 2, and the raw liquid after the dosing flows into the liquid storage tank 10, and then the air pump 5 is started, The gas entering from the intake pipe 6 is compressed and circulated into the liquid storage tank 10, so that the compressed gas is mixed with the stock solution in the liquid storage tank 10, and the stirring frame 36 is started, so that the stirring frame 36 is aligned with the liquid storage tank 10. The internal compressed gas is fully mixed with the stock solution and the reaction agent. After stirring for a period of time, the stirring frame 36 stops stirring. At this time, the oil filter p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com