Modified cold resistant polyvinyl ethylene (PVC) soft plastic and preparation method thereof

A polyvinyl chloride and cold resistance technology, which is applied in the field of modified cold resistance soft polyvinyl chloride plastics and its preparation, can solve the problems of limited improvement effect of cold resistance, insignificant improvement of cold resistance, easy migration and precipitation, etc. Achieve remarkable cold resistance, good cold resistance, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

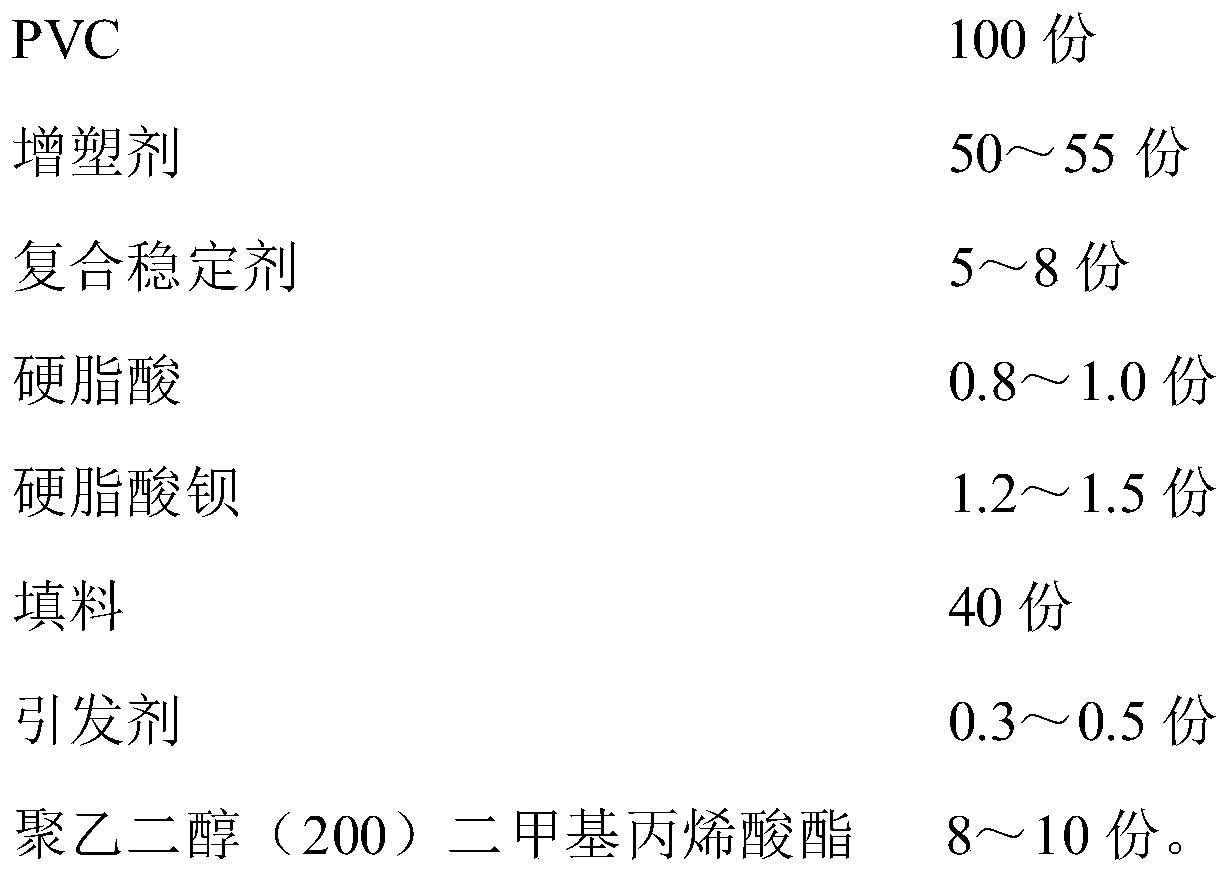

[0033] Modified cold-resistant polyvinyl chloride soft plastic, composed of the following raw materials according to weight fraction:

[0034]

[0035] The preparation method of the modified cold-resistant polyvinyl chloride soft plastic comprises the following steps:

[0036] (1) Preparation of PVC compound: Add PVC, calcium-zinc composite stabilizer, barium stearate, and stearic acid into the high-speed mixer in turn according to the formula ratio, stir for 2 minutes, heat up to 90°C, add DOP and stir 6 minutes, finally add calcium carbonate and stir for 3 minutes to make PVC mixture, discharge for subsequent use;

[0037] (2) Preparation of the mixture: according to the formula ratio, DCP and polyethylene glycol (200) dimethacrylate are mixed into a mixture;

[0038] (3) Feeding: the above-mentioned PVC compound is added with the feed rate of 85kg / h to the first feed port of the twin-screw extruder with 110r / min operating speed; the above-mentioned DCP and Polyethylene ...

Embodiment 2

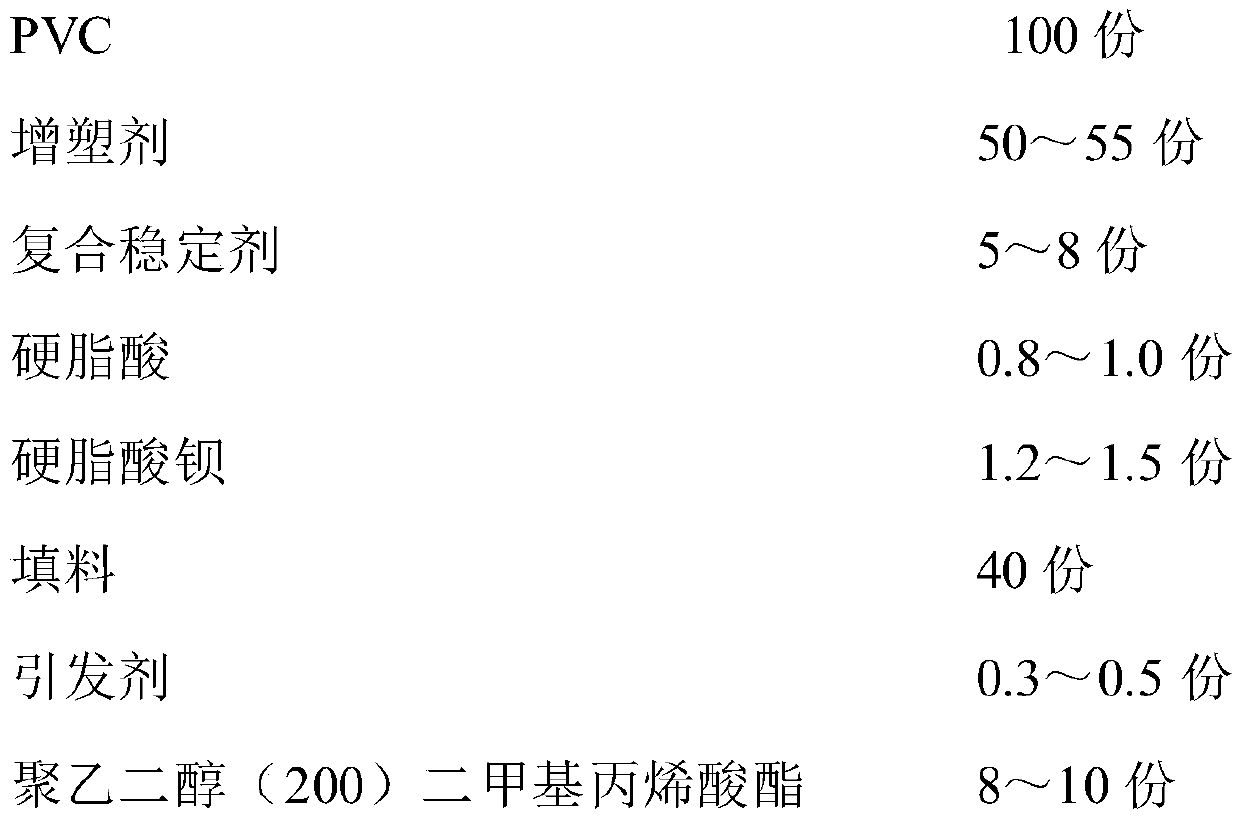

[0045] Modified cold-resistant polyvinyl chloride soft plastic, composed of the following raw materials according to weight fraction:

[0046]

[0047] The preparation method of the modified cold-resistant polyvinyl chloride soft plastic comprises the following steps:

[0048] (1) Preparation of PVC compound: Add PVC, calcium-zinc composite stabilizer, barium stearate, and stearic acid into the high-speed mixer in turn according to the formula ratio, stir for 3 minutes, then heat up to 95°C, add DOP and stir 6 minutes, finally add calcium carbonate and stir for 3 minutes to make PVC mixture, discharge for subsequent use;

[0049] (2) Preparation of the mixture: according to the formula ratio, DCP and polyethylene glycol (200) dimethacrylate are mixed into a mixture;

[0050] (3) Feeding: the above-mentioned PVC compound is added with the feed rate of 85kg / h to the first feed port of the twin-screw extruder with 110r / min operating speed; the above-mentioned DCP and Polyethy...

Embodiment 3

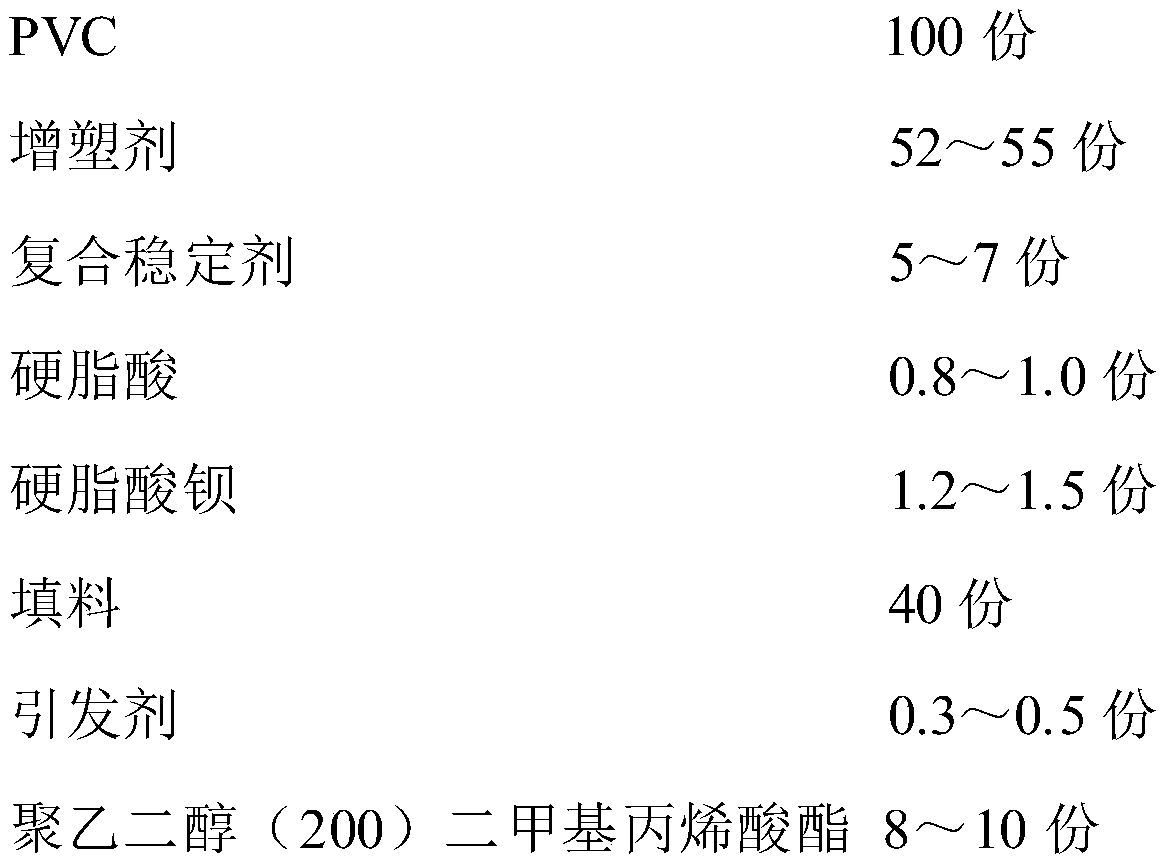

[0057] Modified cold-resistant polyvinyl chloride soft plastic, composed of the following raw materials according to weight fraction:

[0058]

[0059]

[0060] The preparation method of the modified cold-resistant polyvinyl chloride soft plastic comprises the following steps:

[0061] (1) Preparation of PVC compound: Add PVC, calcium-zinc composite stabilizer, barium stearate, and stearic acid into the high-speed mixer in turn according to the formula ratio, stir for 3 minutes, then heat up to 90°C, add DOP and stir 6 minutes, finally add calcium carbonate and stir for 3 minutes to make PVC mixture, discharge for subsequent use;

[0062] (2) Preparation of the mixture: according to the formula ratio, DCP and polyethylene glycol (200) dimethacrylate are mixed into a mixture;

[0063] (3) Feeding: the above-mentioned PVC compound is added with the feed rate of 85kg / h to the first feed port of the twin-screw extruder with 110r / min operating speed; the above-mentioned DCP ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com