Liquid metal 5G filter

A liquid metal and filter technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of small size, inconvenient operation, time-consuming and labor-intensive, etc., and achieve the effect of improving service life, convenient fixed installation, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

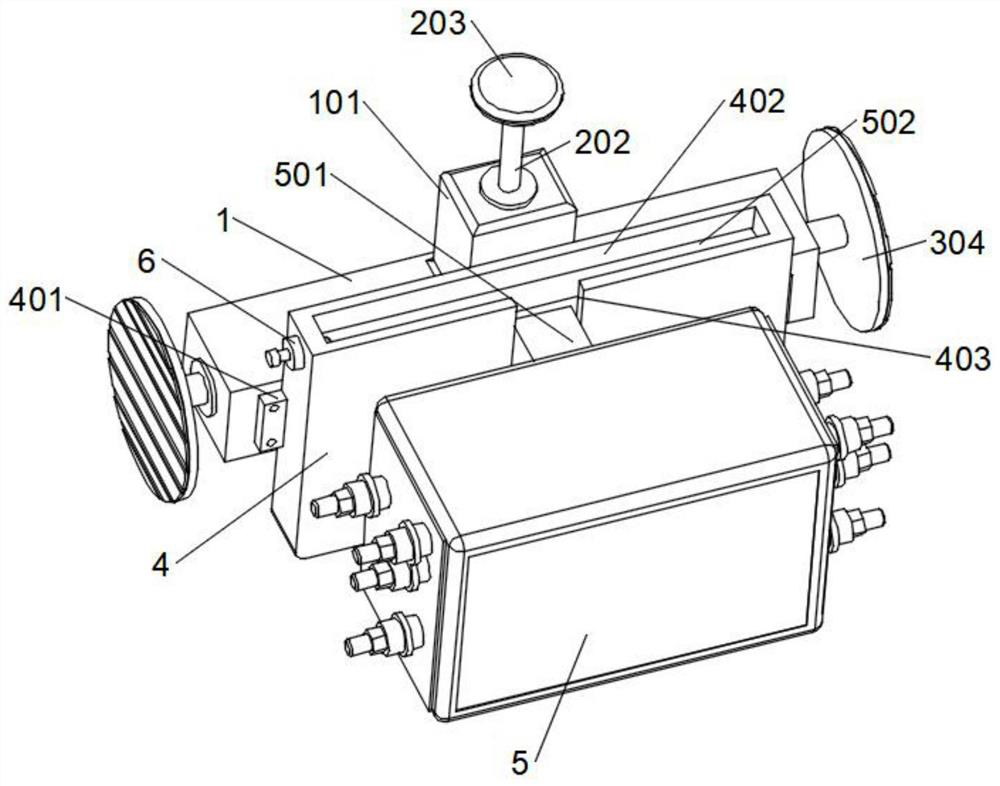

[0033] refer to Figure 1-5 A liquid metal 5G filter shown includes a horizontal frame 1, a mounting block 4 and a filter body 5. An end block 101 is fixedly installed in the middle of the upper surface of the horizontal frame 1, and a propulsion assembly is arranged inside the end block 101. The horizontal frame 1. There are supporting components on both sides of the interior that can be pressure-guided and matched with the propulsion component. The front side of the horizontal frame 1 is provided with a mounting block 4. Two sets of mounting supports 401 are symmetrically fixed on both sides of the mounting block 4, and the mounting block 4 passes through The installation support 401 is fixedly connected with the front side surface of the cross frame 1, the filter body 5 is movably installed on the front side of the installation block 4, and the end column 6 is fixedly installed on the left side surface of the installation block 4 close to the upper surface of the installatio...

Embodiment 2

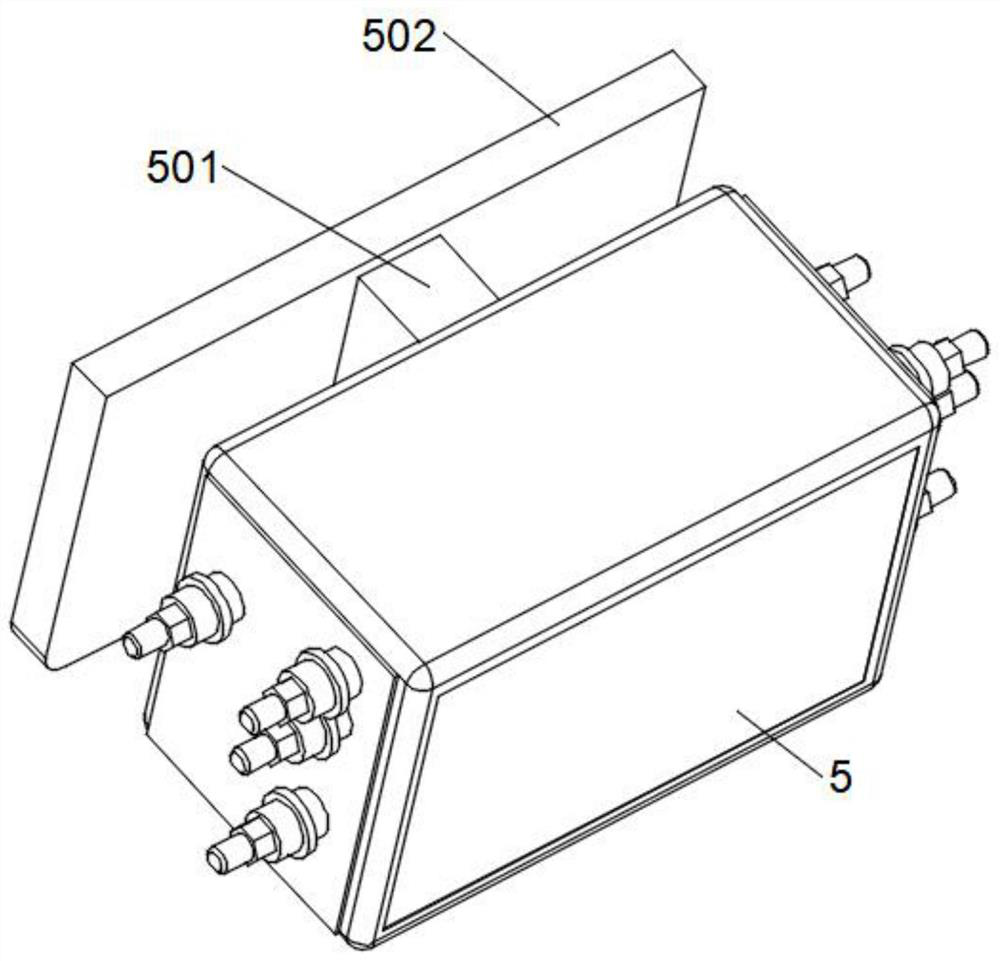

[0036] to combine figure 1 , figure 2 and Figure 4 As shown, based on the above-mentioned embodiment 1, the upper surface of the installation block 4 is provided with a sliding slot 402, and the front surface of the installation block 4 is provided with a relief notch 403, and the relief notch 403 communicates with the sliding slot 402, and the filter The rear surface of the main body 5 is fixedly installed with a connecting fast 501, and the rear surface of the connecting fast 501 is fixedly installed with a sliding mounting plate 502, and the sliding mounting plate 502 is slidably inserted into the sliding slot 402, and the connecting fast 501 is limited and slidably inserted. Align and insert the sliding mounting plate 502 into the sliding slot 402 inside the step-off notch 403. The sliding slot 402 facilitates the insertion of the sliding mounting plate 502, and the step-off notch 403 makes room for connecting the fast 501. snapped in, thereby facilitating the installa...

Embodiment 3

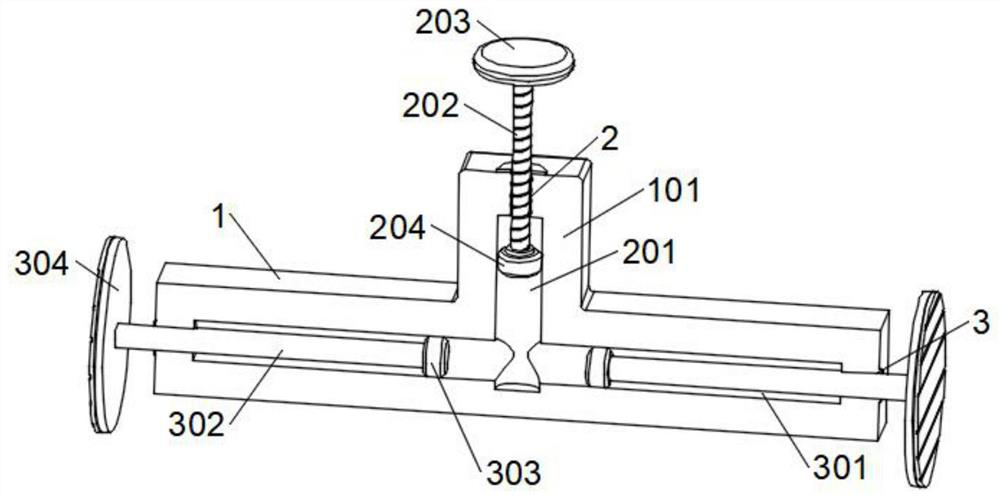

[0038] to combine figure 1 and image 3 As shown, based on the above-mentioned embodiment 1 or 2, the propulsion assembly includes an internally threaded hole 2 opened on the upper surface of the end block 101, and the bottom of the internally threaded hole 2 is provided with a pressure guide hole A201, and the pressure guide hole A201 extends to the cross frame 1, the inner threaded hole 2 is engaged with a threaded rod 202, the upper end of the threaded rod 202 is fixed with a screw cap 203, the end of the threaded rod 202 located in the pressure guide hole A201 is rotated and installed with a piston A204, and the piston A204 is connected to the guide The surface of the inner wall of the pressure hole A201 is slidingly connected, hold the screw cap 203 and twist it, and then drive the threaded rod 202 to rotate to engage with the inner threaded hole 2, and then the threaded rod 202 will push the piston A204 down the inner wall surface of the pressure guiding hole A201 At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com