Wire stripping device with multi-station structure for three-phase motor processing

A technology of three-phase motor and wire stripping device, which is applied in the direction of cable installation, cable installation device, equipment for dismantling/armouring cables, etc. It can solve the problems of broken wires and low efficiency of single wire stripping processing, etc., to ensure cleanliness , Improve stripping efficiency and facilitate storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

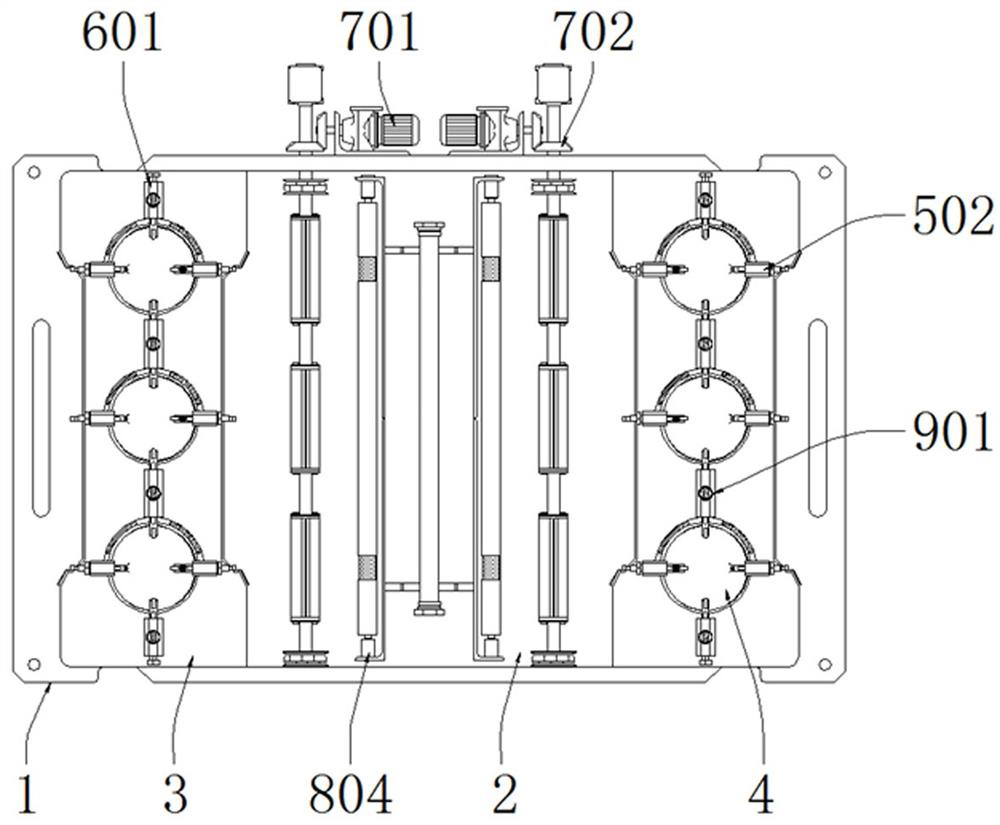

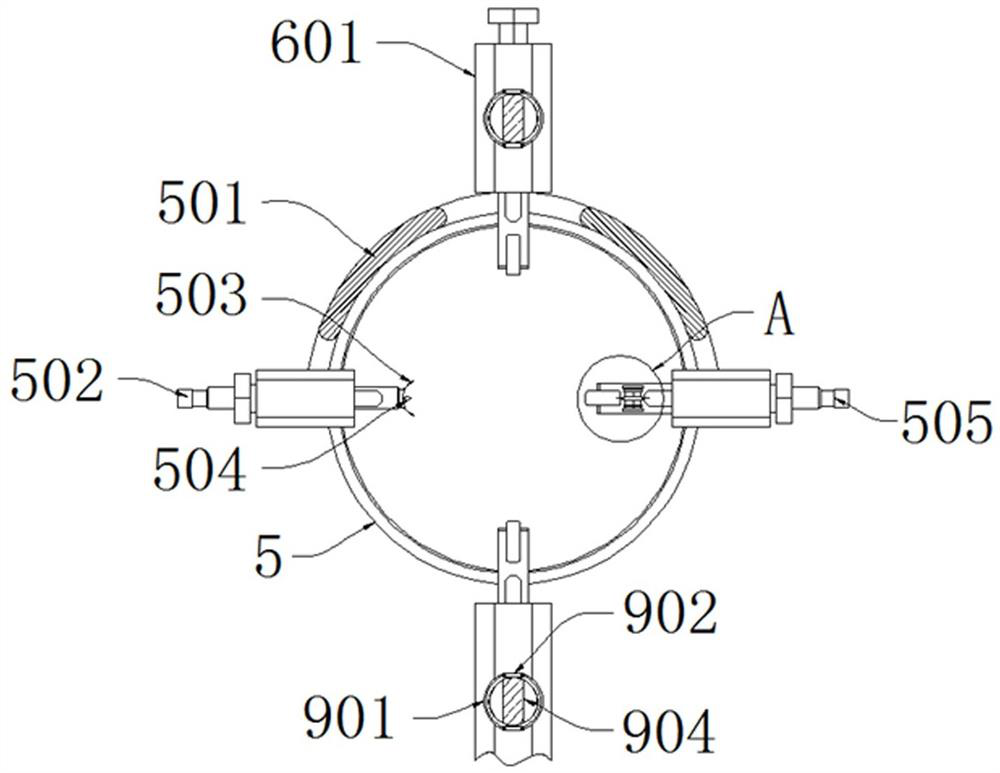

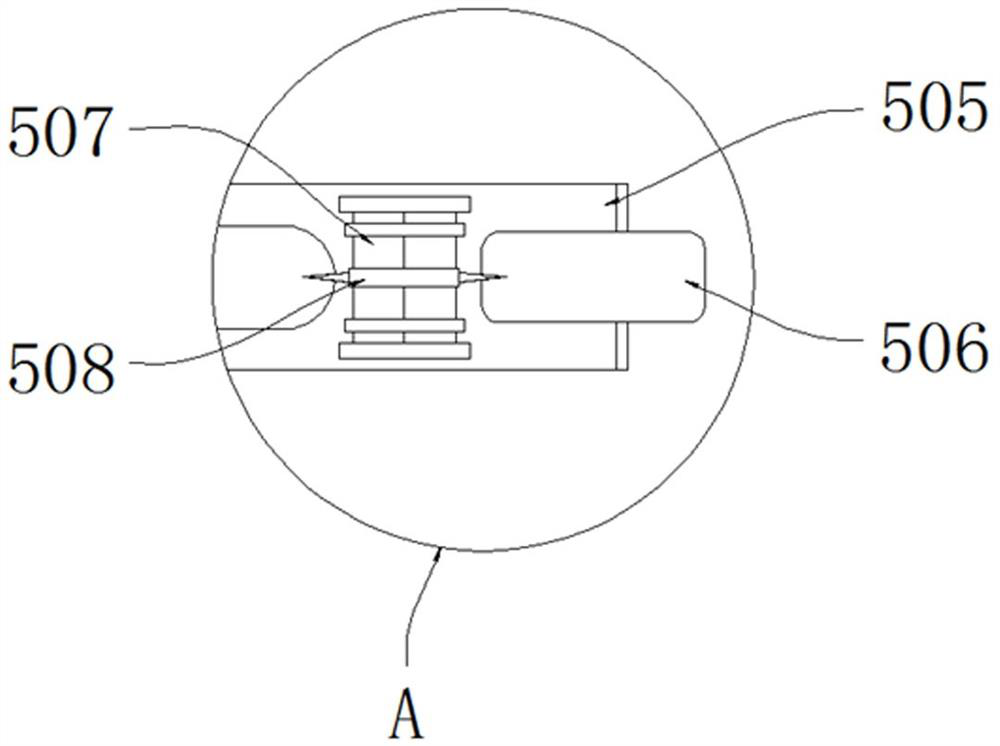

[0030] see Figure 1-8, the present invention provides a technical solution: a wire stripping device with a multi-station structure for three-phase motor processing, including a base 1 and a wire take-up assembly 7, a workbench 2 is installed on the top of the base 1, and one side of the workbench 2 A processing seat 3 is installed, and the surface of the processing seat 3 is provided with a wire stripping groove 4, and the inner wall of the wire stripping groove 4 is installed with a wire stripping assembly 5, and an auxiliary assembly 6 is arranged on one side of the wire stripping assembly 5, and the wire stripping assembly 5 includes an arc frame 501 , the first electric telescopic rod 502, the protective sheet 503, the peeling knife 504, the second electric telescopic rod 505, the limit top wheel 506, the rotating bracket 507 and the split cutter head 508, and the left side of the arc frame 501 is pierced with the first electric Telescopic rod 502, the output end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com