Self-disinfection medical non-woven fabric instrument

A cloth instrument and end face technology, which is applied in the field of textile disinfection, can solve the problems of single disinfection function of transmission disinfection equipment, difficulty in controlling the spraying of disinfectant on non-woven fabrics, and high cost consumption, so as to reduce energy consumption, improve work efficiency, and evenly Disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objects and advantages of the present invention, the present invention will be specifically described below, and The method is not rigorously defined, as used in this article, as used herein, the terms upper and lower and left and right are not limited to its rigorous geometric definition, but is included for the rationality of machining or human error rationality and inconsistency. The specific characteristics of the self-disinfection medical nonwoven fabric:

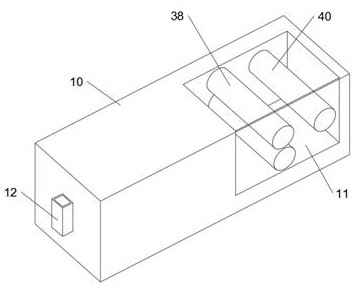

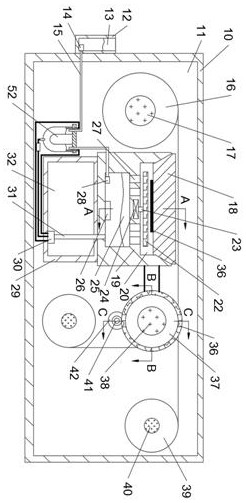

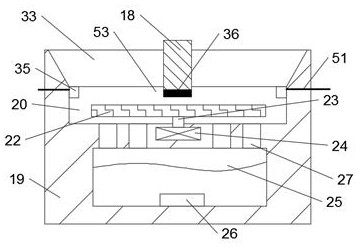

[0021] Referring to the drawings, a self-disinfection medical nonwoven fabric, including a housing 10 in accordance with an embodiment of the present invention, and an inner cavity 11 is fixed to the left surface of the outer casing 10. 12. The water tank 12 is provided with a water chamber 13, and the inner wall of the inner cavity 11 is rotated to be connected to the shaft 17, and the arrangement shaft 17 is fixedly provided with a plahery 16, the platen 16 The right side is provided with a cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com