Mixing and tempering bin for burdening

A technology of conditioning and mixing bins, applied in mixers, mixers with rotary stirring devices, applications, etc., can solve the problems of unsatisfactory stirring effect, occupied space, and unsatisfactory effect, and achieve reasonable structure. Stable, increased feeding efficiency, stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

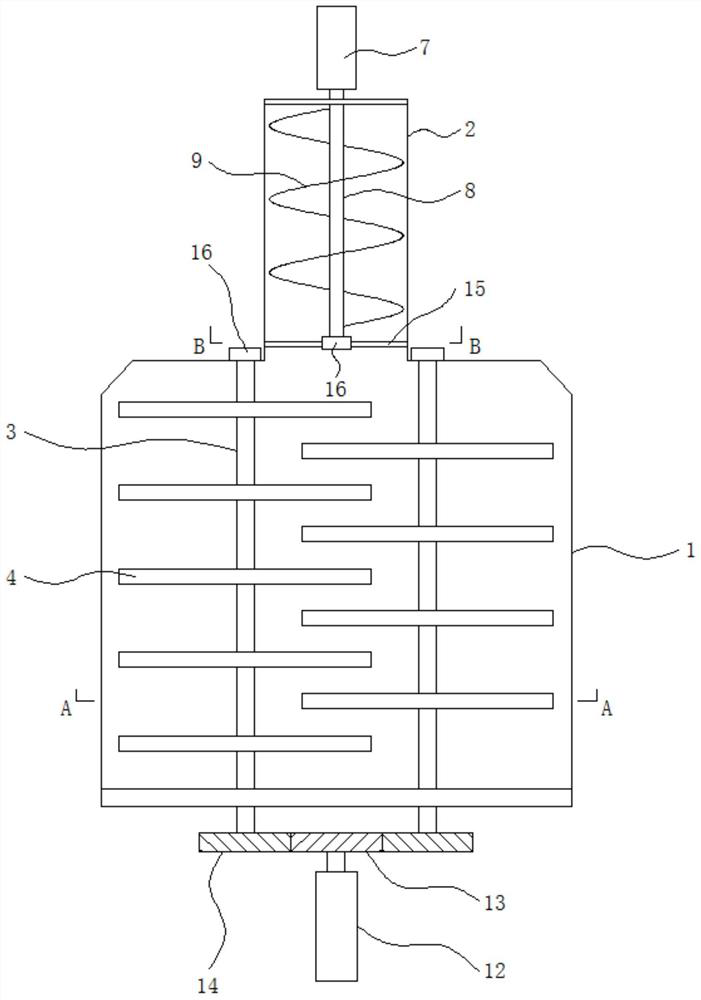

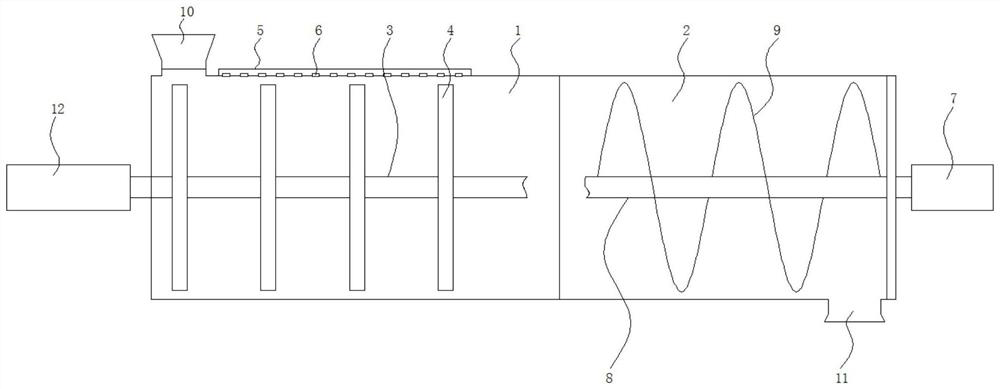

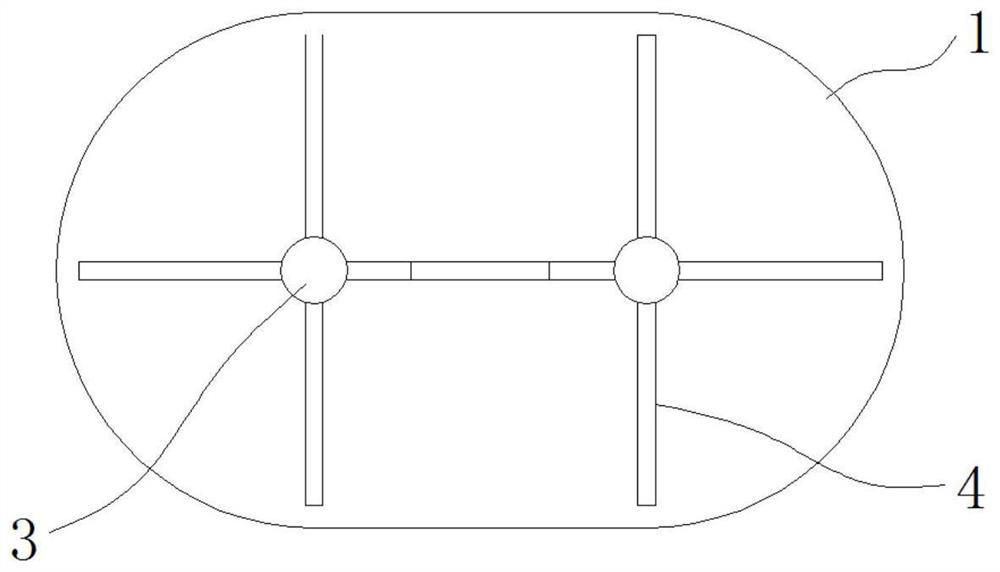

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a mixing and tempering bin for batching includes a double-barrel mixing bin 1 and a single-barrel feeding bin 2; two parallel mixing shafts 3 are installed in the double-barrel mixing bin 1, and on the mixing shaft 3 Evenly spaced mixing rods 4 are installed, and the mixing rods 4 on the two mixing shafts 3 are arranged at intervals, and the mixing rods 4 on one mixing shaft 3 are inserted into the other mixing shaft 3 correspondingly. Between two adjacent mixing rods 4, the front ends of the two mixing shafts 3 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com