Metallurgical low-melting-point metal powder hot melting forming equipment

A low-melting-point metal and hot-melt molding technology, which is applied in casting molding equipment, metal processing equipment, casting equipment, etc., can solve the problems of low safety and low work efficiency, reduce labor intensity, prevent hot air loss, and avoid splashing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

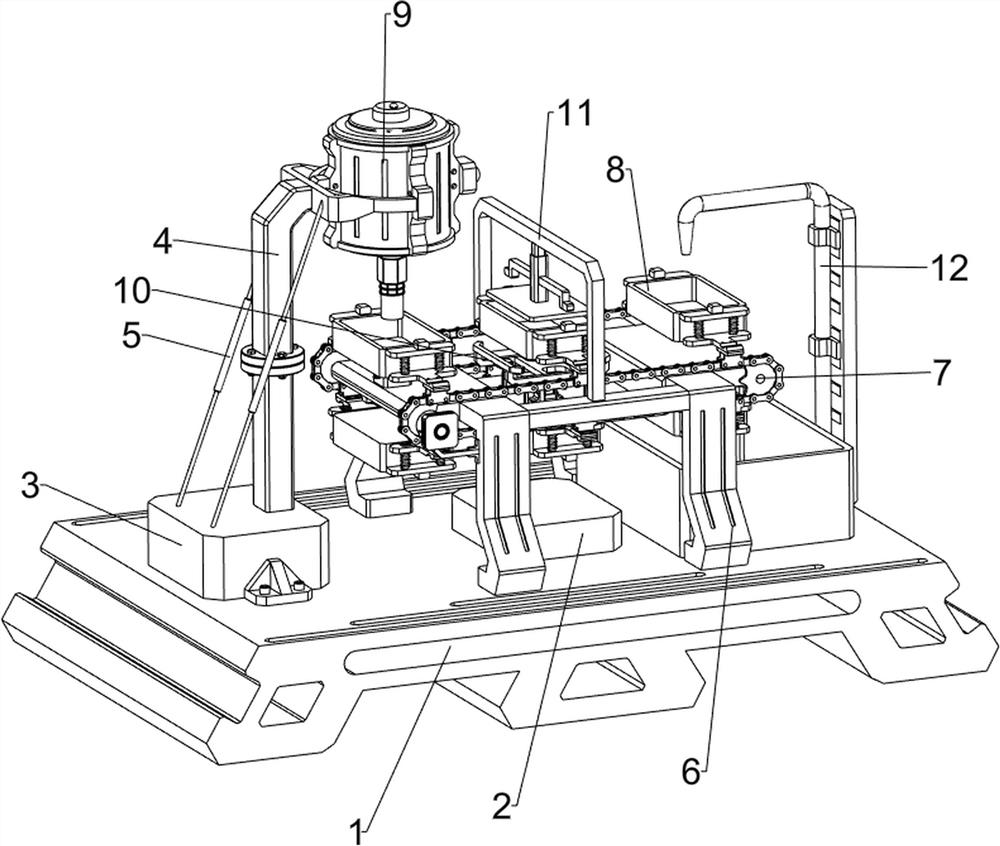

[0031] A metallurgical low melting point metal powder hot melt molding equipment, such as Figure 1-3 As shown, it includes a base 1, a first fixed block 3, a support rod 4, a rope 5, a tripod 6, a transmission mechanism 7 and a bearing mechanism 8, the left side of the top of the base 1 is provided with a first fixed block 3, and the first fixed block 3. The right side of the top is provided with a support rod 4, and a rope 5 is provided symmetrically between the upper left side of the support rod 4 and the left side of the top of the first fixed block 3. A transmission mechanism 7 is connected between them, and a bearing mechanism 8 is connected between the foot frame 6 and the parts of the transmission mechanism 7 .

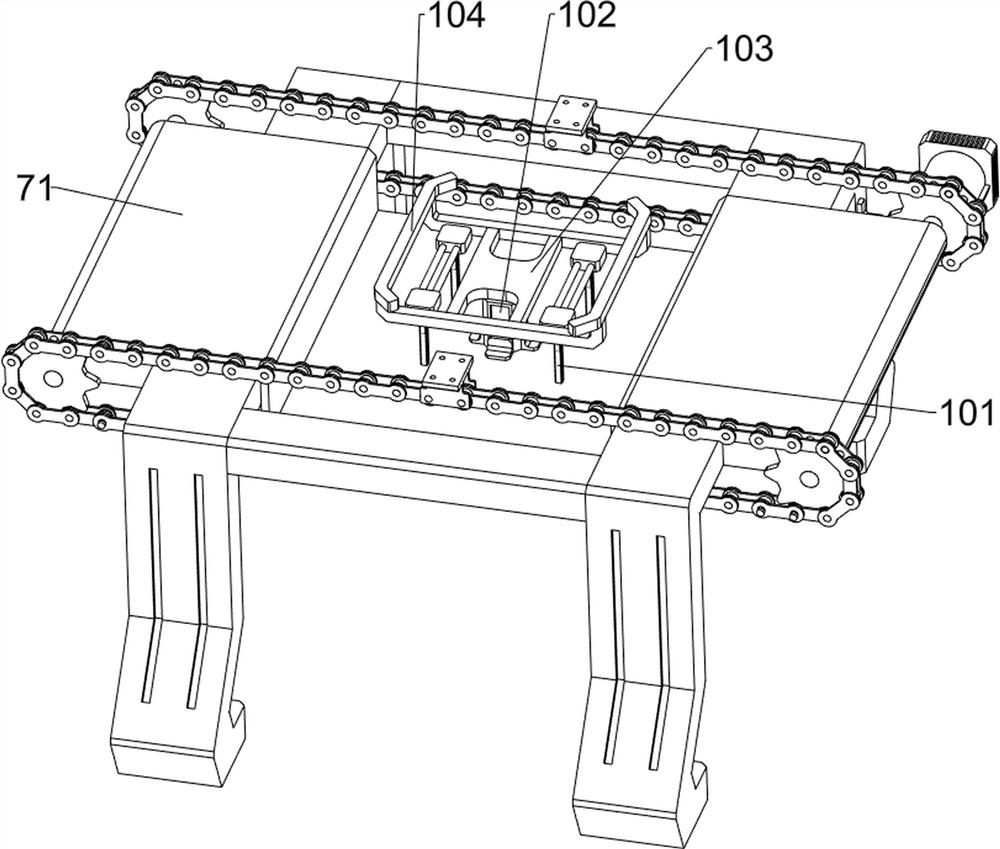

[0032] Transmission mechanism 7 comprises bearing base plate 71, rotating shaft 72, chain 73, drive motor 74, first mounting block 75 and pressure sensor 76, is provided with bearing base plate 71 between tripod 6 tops, and bearing base plate 71 left and right...

Embodiment 2

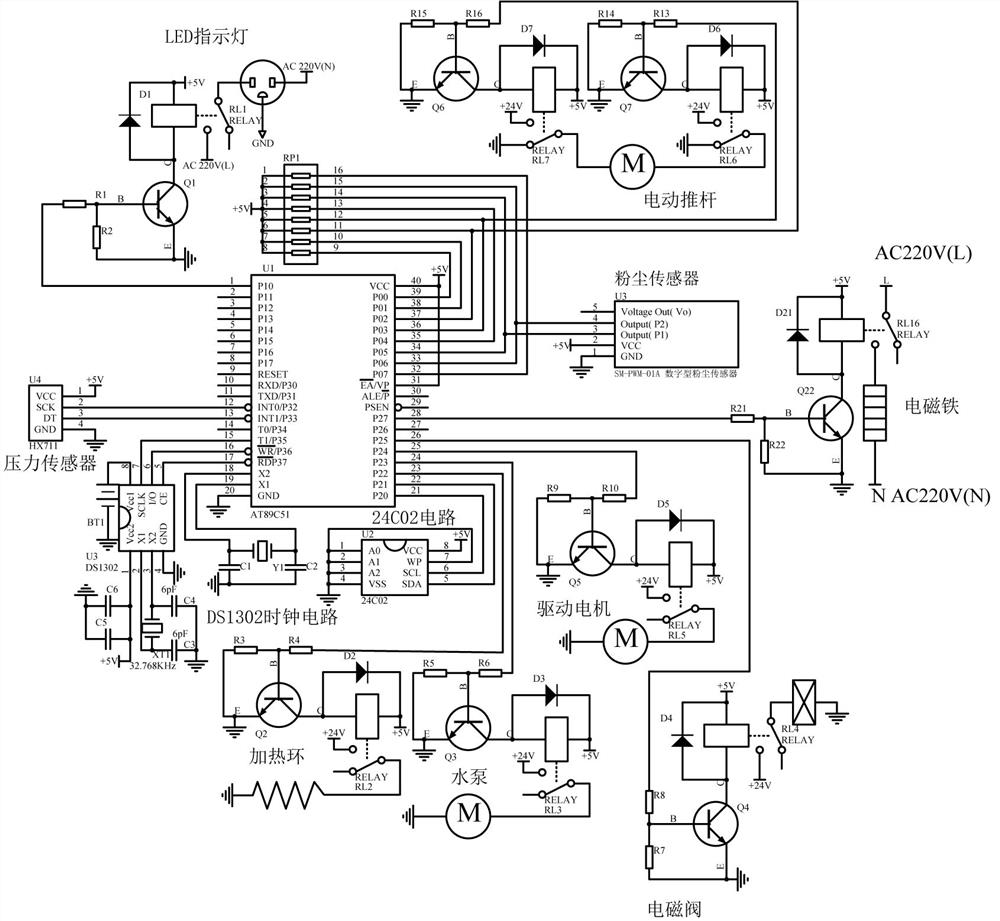

[0036] On the basis of Example 1, such as Figure 4-9As shown, a blanking mechanism 9 is also included, and the blanking mechanism 9 includes a fixed ring 91, an outer wall of the mechanism 92, a top cover 93, a dust sensor 94, an LED indicator light 95, a solenoid valve 96, a mechanism liner 97, and a swivel ring 98 With the first telescopic rod 99, the right side of the upper part of the support rod 4 is provided with a fixed ring 91, the inner side of the fixed ring 91 is provided with a mechanism outer wall 92, and the top of the mechanism outer wall 92 is threadedly equipped with a top cover 93, and the middle part of the top cover 93 is provided with a dust sensor 94 , the right side of the mechanism outer wall 92 is provided with an LED indicator light 95, the bottom of the mechanism outer wall 92 is provided with a discharge port, the middle part of the discharge port is provided with a solenoid valve 96, the mechanism outer wall 92 is provided with a mechanism liner 97...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com