Clamp and method for turning thin-wall dish-shaped part on lathe

A thin-walled, turning technology, used in clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of increasing machining residual material, low material utilization rate, and increasing machining difficulty, achieving efficient turning and improving machining efficiency. Remarkable and guaranteed effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

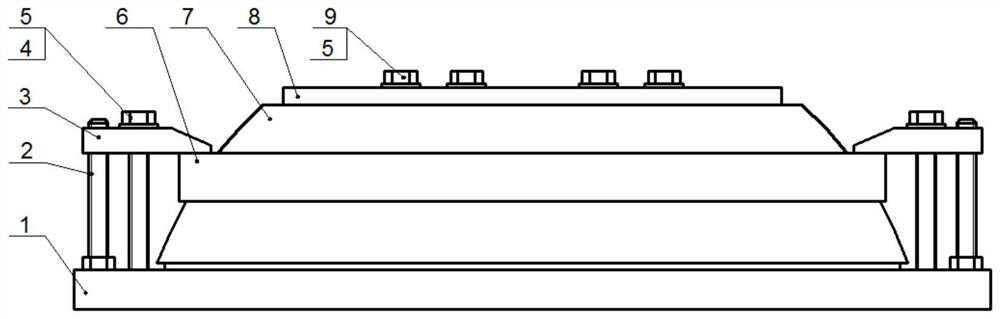

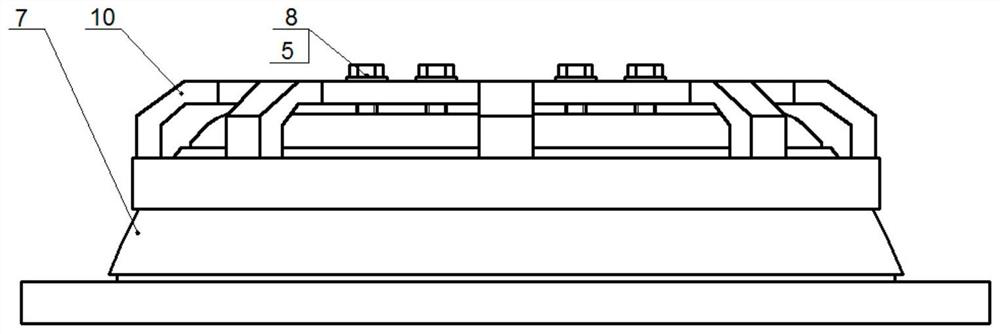

[0069] This embodiment is a fixture for turning thin-walled disc-shaped parts on a lathe. The present invention includes a punch 1, a supporting bolt 2, a first pressing plate 3, a first pressing bolt 4, a gasket 5, a pressing ring 6, a second pressing plate 8, a second pressing bolt 9, and a third pressing plate 10.

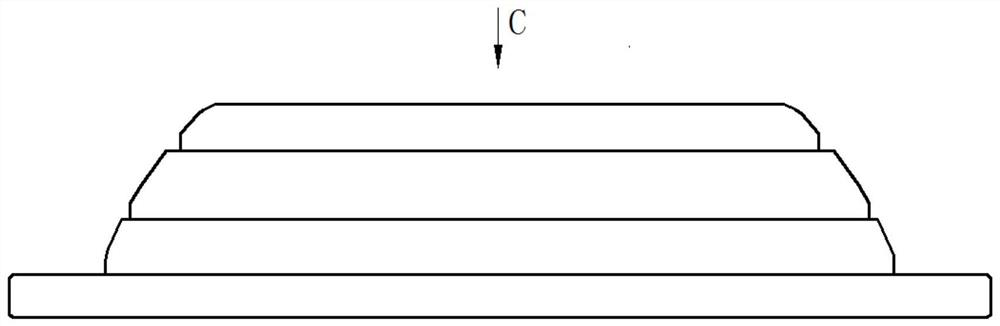

[0070] The fixed body is a welded structure, which is assembled and welded by a splint, a circular body, a positioning ring, a bottom plate, and a rib plate. refer to image 3 , 4 , Shown in 5, punch 1 is a ball crown part with a bottom of 45# steel, and the big end of the ball crown has a chassis. The radius SR of the outer contour of the spherical crown is the same as the radius of the inner arc surface of the workpiece, and the wall thickness of the inner contour and the outer contour is 25mm. There are upper and lower ring grooves on the outer contour surface of the spherical crown, the distances from the end face of the chassis are 97mm and 57mm respecti...

Embodiment 2

[0080] Taking the processing material 30CrMnSiA, the radius of the inner arc of the thin-walled butterfly workpiece is SR246mm, the wall thickness is 2mm, and the height is 42.86mm, and the upper and lower end surfaces of the workpiece require processing of 38 ° conical surface as an example to illustrate how to process and use the present invention. Special processing device.

[0081] Specific operation method during use: Use the general clamping method to clamp the chassis of the punch on the lathe, and use the dial indicator to align the runout of the outer arc surface of the punch and the top surface of the spherical crown within 0.03 mm. First screw the support bolts into the threaded holes of the pressure plate 1, insert the compression bolts 1 into the through holes of the flat gasket and the oblong holes of the pressure plate 1, and then screw them into the evenly distributed threaded holes of the punch chassis. Then insert the workpiece into the outer surface of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com