Novel thread winding hollow glass fiber reinforced plastic rod

A fiberglass and hollow-core technology, applied in plant support, horticulture, botanical equipment and methods, etc., can solve the problems of inconvenient climbing vegetable growth, easy-to-break surface, low corrosion resistance, etc. The effect of improving the service life and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

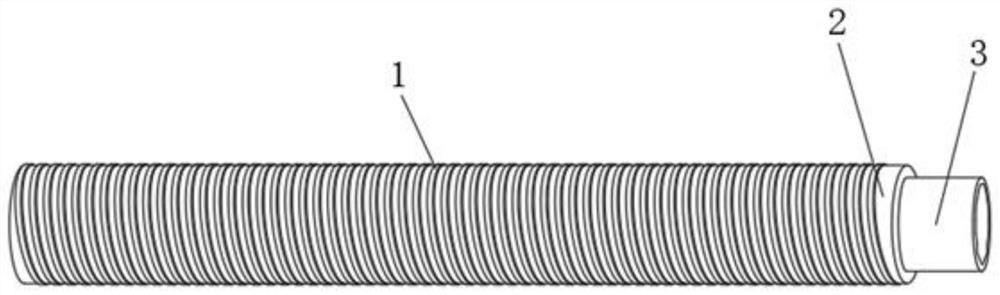

[0027] Such as figure 1 As shown, the embodiment of the present invention provides a novel thread-wound hollow fiberglass rod, comprising a polyester fiber strip 1, the polyester fiber strip 1 is wound on the outer periphery of a longitudinal glass fiber tube 2, and the longitudinal glass fiber tube 2 is arranged on a PE plastic tube 3 exterior.

[0028] A method for preparing a novel thread-wound hollow fiberglass rod, comprising the following preparation steps:

[0029] S1. Prepare a certain amount of high-density polyethylene raw material and 3% black color masterbatch, add the black color masterbatch into the polyethylene raw material, mix and dry, and obtain mixture A, which can be finally obtained through the black color masterbatch The color of the PE plastic pipe 3 is changed. After drying, the mixture A is sent to the hopper through the feeding machine, and the mixture A is sent to the inside of the mold through a meter weight for heating. The meter weight is used to...

Embodiment 2

[0039] Such as figure 1As shown, the embodiment of the present invention provides a novel thread-wound hollow fiberglass rod, comprising a polyester fiber strip 1, the polyester fiber strip 1 is wound on the outer periphery of a longitudinal glass fiber tube 2, and the longitudinal glass fiber tube 2 is arranged on a PE plastic tube 3 exterior.

[0040] A method for preparing a novel thread-wound hollow fiberglass rod, comprising the following preparation steps:

[0041] S1. Prepare a certain amount of high-density polyethylene raw material and 3%-4% black color masterbatch, add the black color masterbatch into the polyethylene raw material, mix and dry to obtain the mixture A, which can be obtained through the black color masterbatch Change the color of the finally obtained PE plastic pipe 3. After drying, send the mixture A to the hopper through the feeding machine, and send the mixture A to the inside of the mold through the meter weight for heating. The meter weight is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com