Comprehensive accelerator masterbatch, preparation method thereof and vulcanized rubber product

A technology of accelerators and colloidal particles, applied in the field of rubber, can solve the problems of high odor and toxicity, achieve good quality, good rubber vulcanization effect, and improve the effect of vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

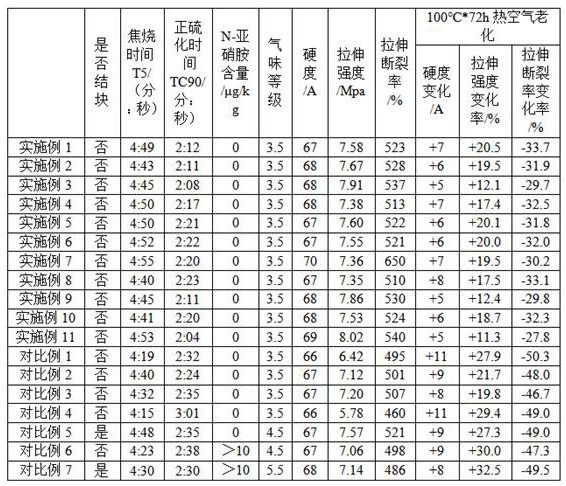

Examples

Embodiment 1

[0053] A kind of comprehensive accelerator masterbatch, its preparation method comprises the following steps:

[0054] ①, Premix:

[0055] Put 9.5kg of EPDM 4045M and 2kg of EVA resin into the internal mixer for mixing, discharge the glue at 120°C, and harvest the masterbatch;

[0056] ②, Mixing: Put the masterbatch harvested in step ① and accelerator ZBEC 17.5kg, accelerator TBTD 5kg, accelerator CLD 5kg, stearic acid 0.75kg, fatty acid zinc 1.25kg and trehalose 0.5kg into the internal mixer Mixing, debinding at 50-65°C, specifically at 60°C in this example, to obtain the compounded material;

[0057] 3. Open refining: send the mixed material obtained in step 2 into the open mill, adjust the roll distance of the open mill to be 1 mm, perform thin pass operation 2 times, and obtain the film;

[0058] ④, granulation: send the film prepared in step ③ into the granulator for cutting and granulation, turn on the blower to dry, and use a vibrating screen to promote the separation...

Embodiment 2-4

[0060] Examples 2-4 On the basis of the method in Example 1, the dosage of the components of the comprehensive accelerator masterbatch is adjusted, and the specific adjustments are shown in Table 1 below.

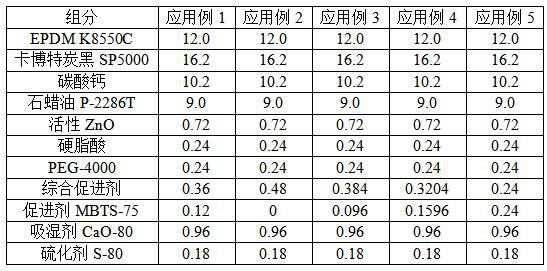

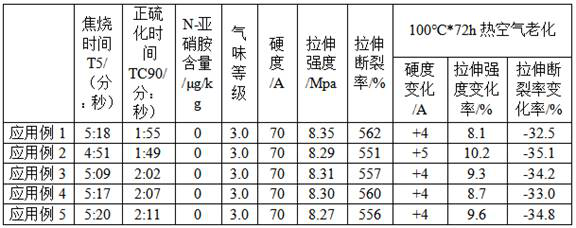

[0061] Table 1 The batching list of Examples 1-11 (unit: kg)

[0062]

Embodiment 5-8

[0064] In Examples 5-8, on the basis of the component distribution ratio and method of Example 3, the component distribution ratio of the rubber matrix is adjusted, and the specific adjustment conditions are shown in Table 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Mooney viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com