Microorganism detection and analysis instrument convenient for slice analysis

A technology for microbial detection and analysis instruments, applied in biochemical instruments, bioreactors/fermenters for specific purposes, enzymology/microbiology devices, etc. Stress state, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

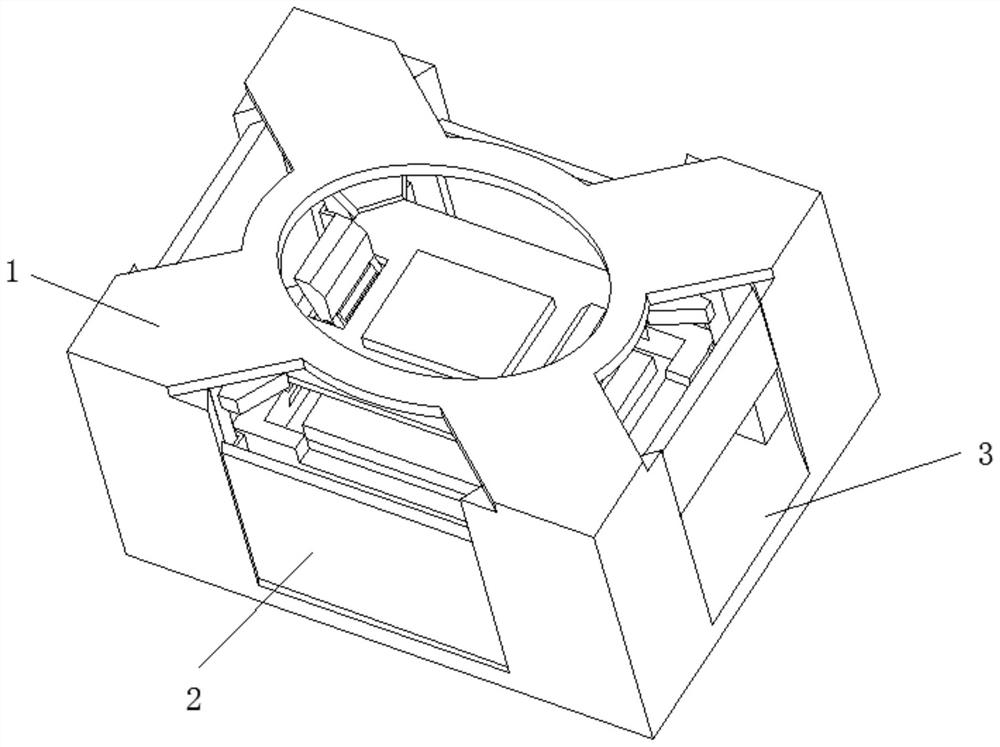

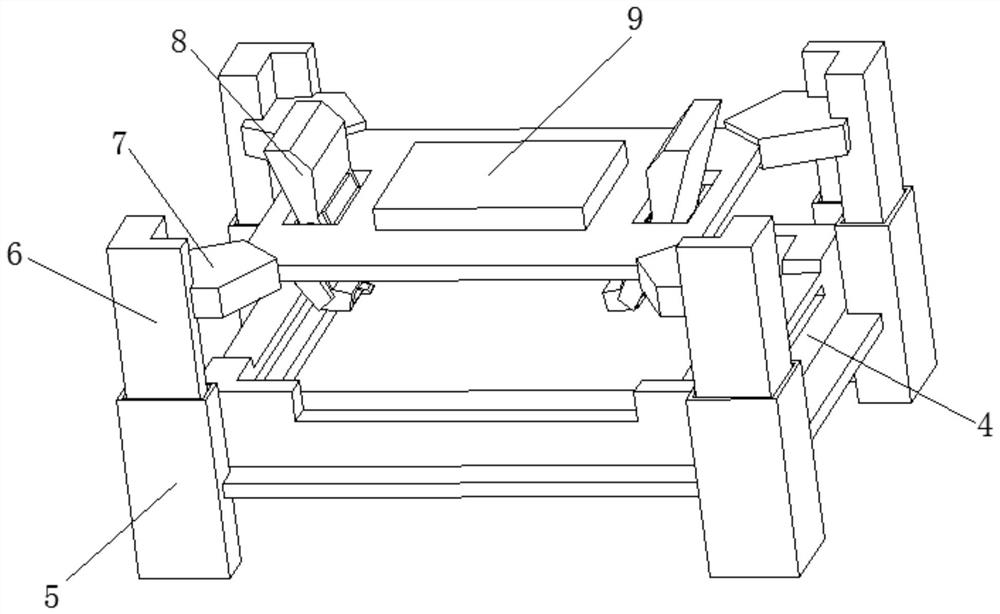

[0036] like Figure 1-3 As shown, the present invention provides a technical solution: a microbial detection and analysis instrument that is convenient for slice analysis, including an instrument rack 1, the front of the instrument rack 1 is fixedly connected with a partition 2, and the two sides of the instrument rack 1 are provided with There is a slicing outlet 3, and the bottom of the inner cavity of the instrument rack 1 is fixedly connected with an inner support shell 5, and the inside of the inner support shell 5 is provided with an inner damping rod 6, and the inner damping rod 6 is fixed between the opposite sides. A fixed block 7 is connected, and a lower pressure plate 9 is fixedly connected between the fixed blocks 7, and an operating device 8 is rotated inside the lower pressure plate 9, and a fixing device 4 is fixedly connected between the opposite sides of the inner support shell 5 , and the fixing device 4 is arranged directly below the operating device 8;

...

Embodiment 2

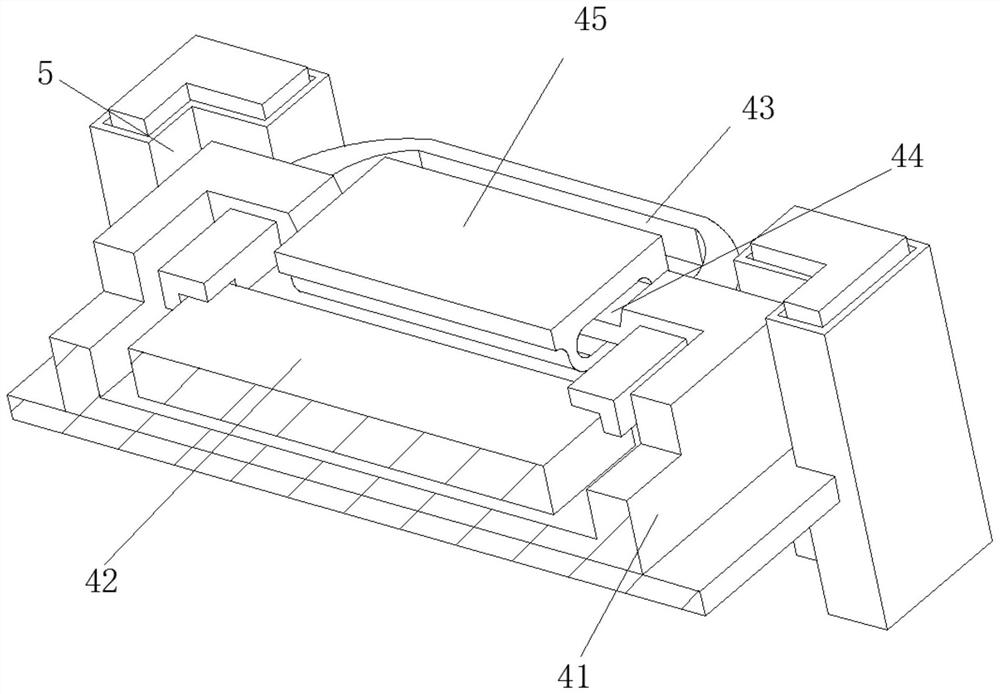

[0042] like Figure 4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the locking device 45 includes a locking block 451, and a first spring 452 is fixedly connected to the depression at the top of the locking block 451, and the first spring 452 An end of a spring 452 away from the locking block 451 is fixedly connected with a built-in sliding block 456 .

[0043] The lower surface of the built-in slider 456 is fixedly connected with a bending rod 453, and the front of the locking block 451 is fixedly connected with an elastic limit rod 455, and the outer surface of the bend rod 453 is slidably arranged on the elastic limit rod. The interior of the 455.

[0044] The bottom end of the bending rod 453 is fixedly connected with an inserting cone 454, and the outer surface of the inserting cone 454 is compatible with the culture plate 42, and the inside of the locking block 451 is provided with a slide hole 457, and the slide The insi...

Embodiment 3

[0048] like Figure 5-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the operating device 8 includes an operating arm 81, and the inner rotation of the operating arm 81 is connected with a first rotating shaft 82. Both ends of the first rotating shaft 82 are fixedly connected to the inside of the lower pressing plate 9 , the bottom of the operating arm 81 is fixedly connected to a second rotating shaft 86 , and both ends of the second rotating shaft 86 are rotatably connected to a block 83 .

[0049] A slicing device 84 is fixedly connected to the bottom of the clamping block 83 , a limiting block plate 85 is fixedly connected to the outer surface of the operating arm 81 , and the bottom of the limiting block plate 85 is fixedly connected to the top of the slicing device 84 . Through the cooperation between the first rotating shaft 82 and the second rotating shaft 86, when the operator rotates the operating arm 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com