Warp knitting transverse moving device and warp knitting machine

A traversing device and warp knitting technology, applied in the field of warp knitting machines, can solve the problems of glue aging, non-compliance with environmental protection requirements, difficulty in maintaining veil fixation for a long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The preparation method of the plush fabric comprises the following steps: veil warping, core yarn warping → machine weaving → gray cloth slitting → gray cloth combing → gray cloth ironing → gray cloth presetting → gray cloth dyeing (except yarn-dyed, no need Dyeing), softening→drying of colored cloth→colored cloth wool (except for single-sided plush, which does not need to be brushed)→colored cloth blowing (mainly for wool-like products, other products can be selectively blown or not) →Combing the colored cloth→Scalding the colored cloth→Shearing the colored cloth→Shaking the colored cloth→Shaping the finished product of the colored cloth.

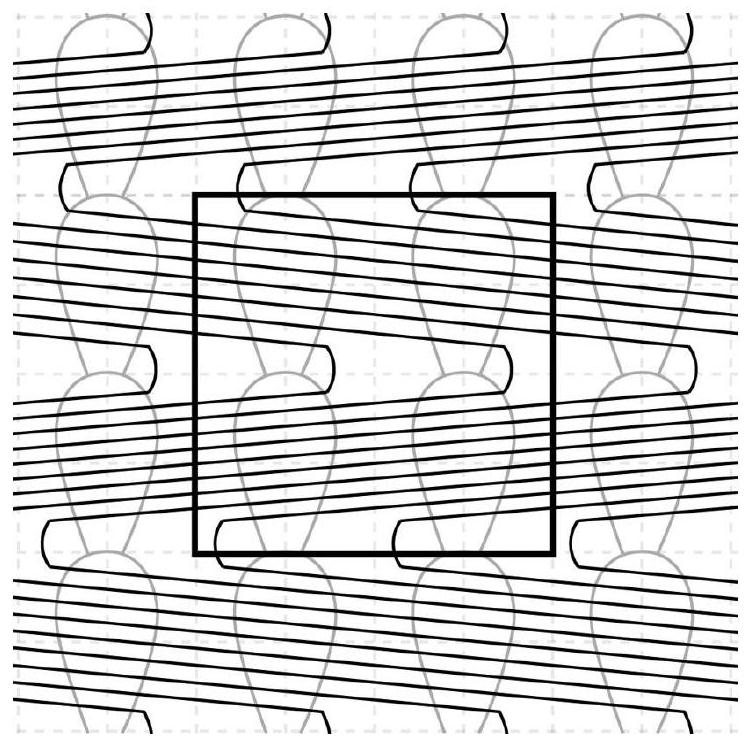

[0077] During the weaving process, the number of comb bars is i, and 5≤i≤8. Specifically, when i=5, GB 1 、GB 2 and GB 4 、GB 5 Configure core yarn; when i=6, GB 1 、GB 2 and GB 5 、GB 6 Configure core yarn; when i=7, GB 1 、GB 2 and GB 6 、GB 7 Configure core yarn or GB 1 , GB 2 、GB 3 and GB 5 、GB 6 、GB 7 Configure the ...

Embodiment 1

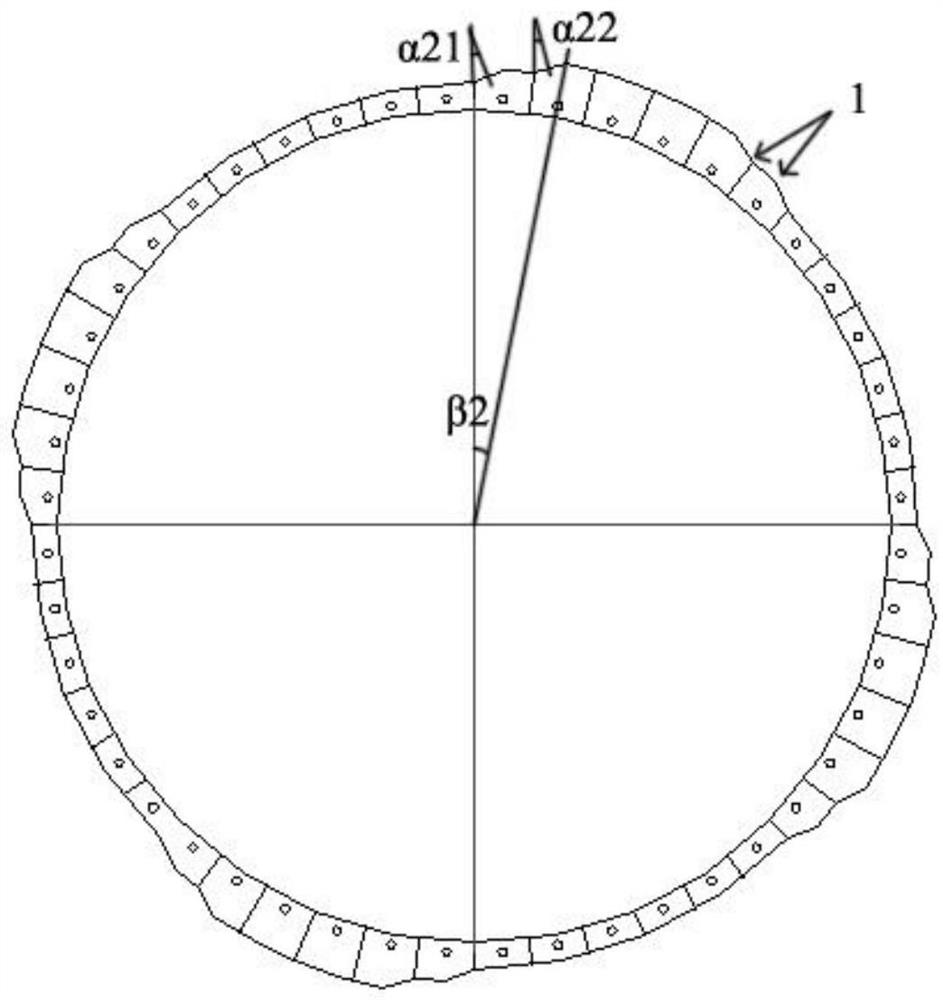

[0102] Such as image 3 Shown is a schematic diagram of a faceplate structure in the six-stroke process (this figure is also a scaled-down view of one of the schemes).

[0103] The flower disc is equally divided into 8 rows along the circumference. The transition point 1 of the slope surface can be a straight line transition as shown in the figure, or a transition of an arc surface, so that it is smoother to use.

[0104] On the outer surface of the faceplate, two slopes are formed between adjacent rows, and the pressure angles α21 and α22 of the slopes are both between 15° and 35°, while the thrust motion angle β2 between adjacent rows is between Between 7.5° and 82.5°.

Embodiment 2

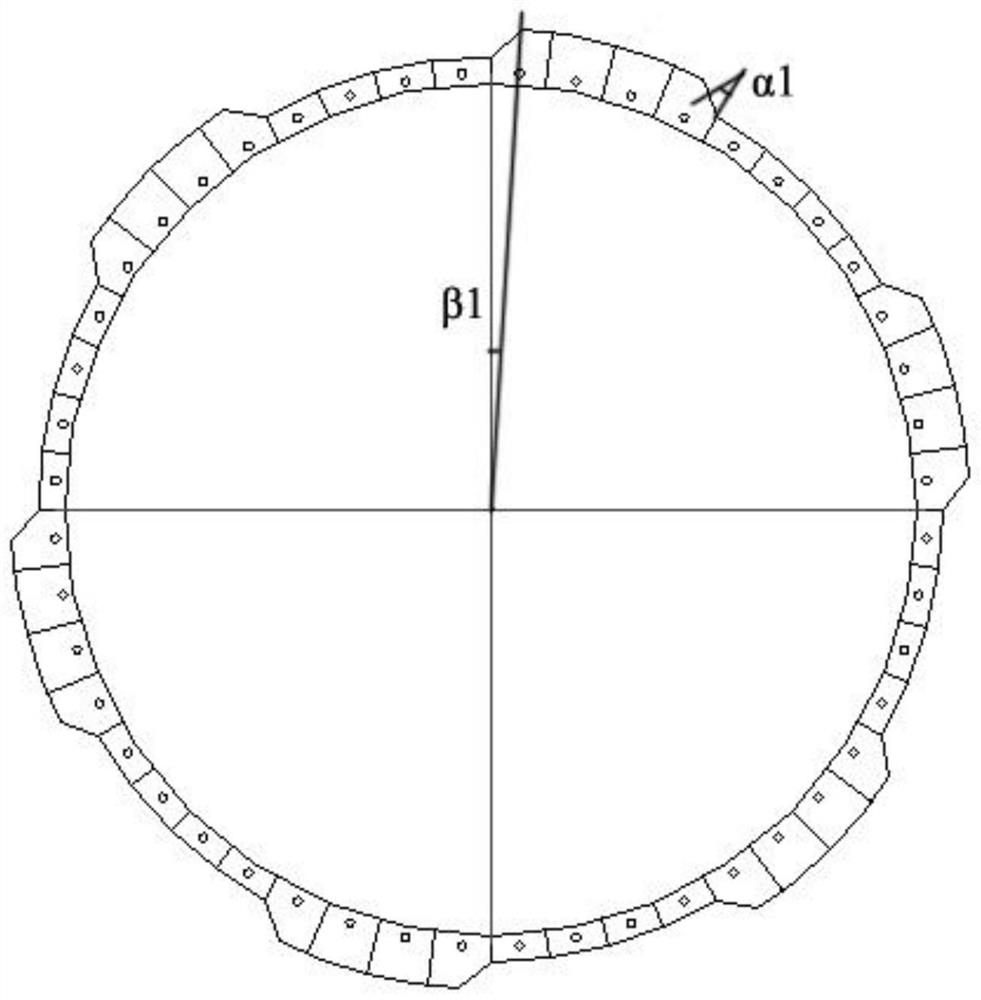

[0106] Such as Figure 4 Shown is a schematic diagram of a faceplate structure in the eight-stroke process (this figure is also a scaled-down view of one of the schemes).

[0107] The flower disc is evenly divided into 6 rows along the circumference.

[0108] On the outer surface of the flower disc, three slopes are formed between adjacent rows, and the pressure angles of the slopes are respectively between 10° and 15°, while the thrust movement angle between adjacent rows is between 7.5° and 82.5° between.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Longitudinal tear strength | aaaaa | aaaaa |

| Longitudinal tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com