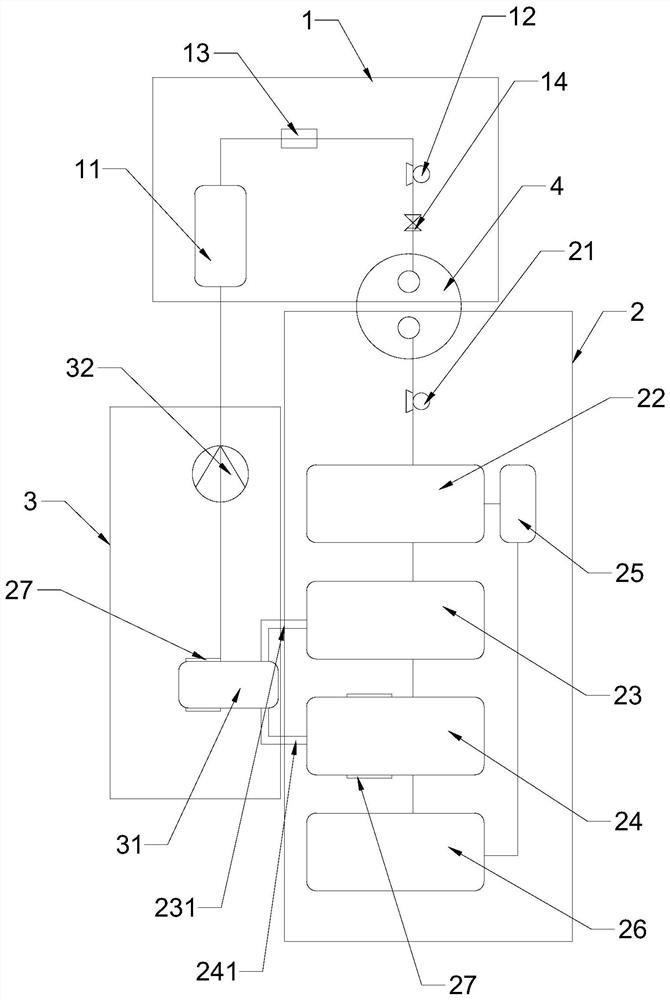

Oil field carbon dioxide injection huff-puff oil extraction ground device

A carbon dioxide and ground device technology, which is applied in the fields of mining fluid, earthwork drilling, sustainable manufacturing/processing, etc., can solve the problems of inability to recover pure carbon dioxide, achieve the effects of improving recovery rate, reducing working pressure and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

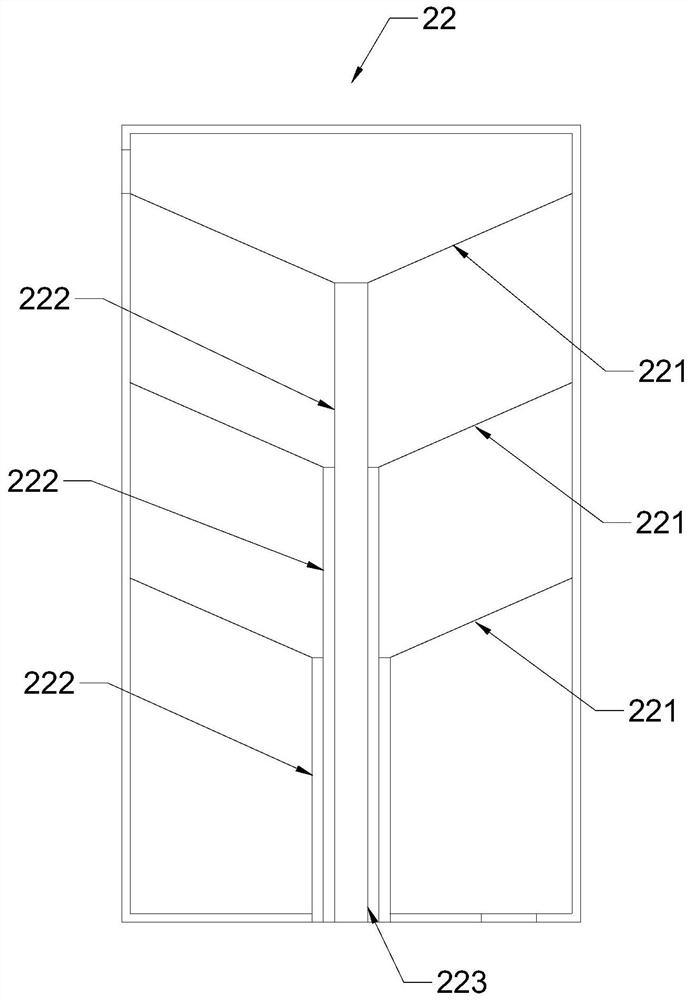

[0050] Embodiment 1: as figure 2 As shown, the filter screen 221 in the multi-stage slag removal tank 22 in this embodiment is set as a funnel shape with a low center and high surroundings. The slag removal tank 22 forms a slag discharge hole 223;

[0051] The slag discharge pipe 222 of each adjacent two layers of filter screens 221 is set in the form of step-by-step sleeves, and the slag discharge pipe 222 of the filter screen 221 near the inlet end of the multi-stage slag removal tank 22 is located on the inner side, away from the multi-stage slag removal tank 22 The slag discharge pipe 222 of the filter screen 221 at the inlet end is located on the outside.

[0052] By arranging the multi-stage slag removal tank 22 in the above-mentioned form, the multi-stage slag removal tank 22 can realize the filtering form of graded filtration, and the larger solid dross is blocked by the filter screen 221 near the inlet end of the multi-stage slag removal tank 22 , and the smaller s...

Embodiment 2

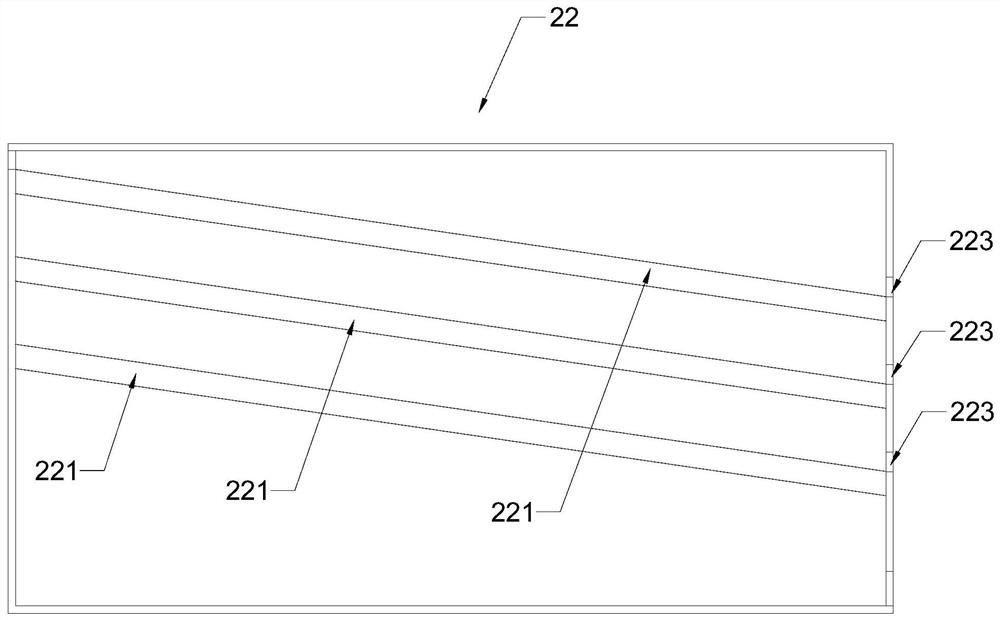

[0054] Embodiment 2: as image 3 with Figure 4 As shown, the filter screen 221 of the multi-stage slag removal tank 22 in this embodiment is set as a C-shaped curved plate in cross section, and the opening of the filter screen 221 faces upwards and goes from high to low inside the multi-stage slag removal tank 22 It is arranged obliquely, and several filter screens 221 are parallel to each other.

[0055] By setting the filter screen 221 in the form of a C-shaped curved plate, and making the openings of the multi-screen screens face to the upper side, the filter screen 221 can accept the crude oil flowing in from the inlet end of the multi-stage slag removal tank 22, and make the filtered The solid dregs that are filtered by the net 221 are collected at the bottom of the filter screen 221; by setting the filter screen 221 in a form that is inclined from high to low, the solid dregs that stay on the filter screen 221 can be removed under the action of their own gravity. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com