Nuclear power-based liquefied natural gas floating storage and regasification unit (LNG-FSRU) regasification system

A technology of LNG-FSRU and liquefied natural gas, which is applied in the field of liquefied natural gas floating regasification, can solve problems such as marine environmental hazards, achieve high nuclear energy utilization, considerable economy, and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

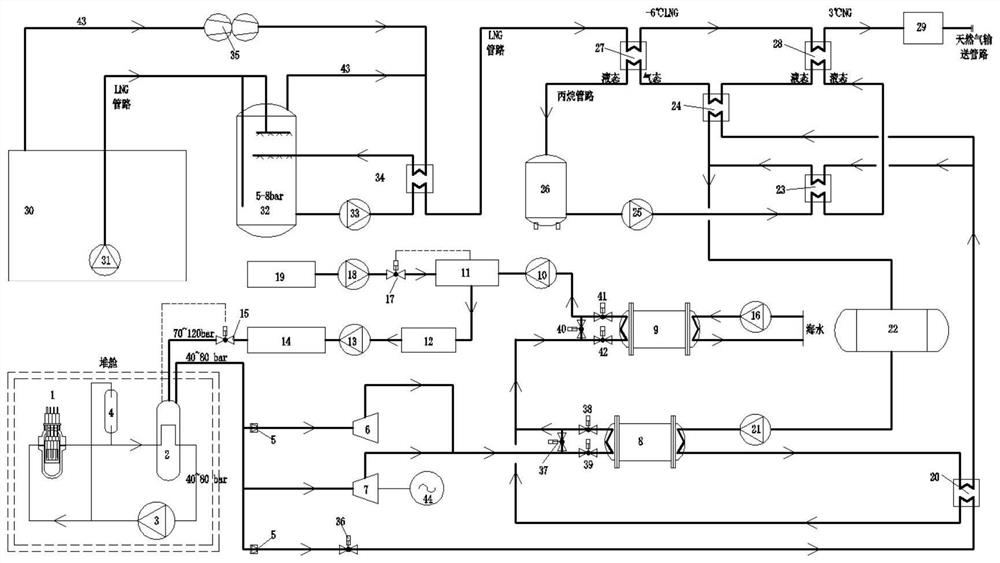

[0030] Such as figure 1 The shown regasification system of a liquefied natural gas floating regasification unit (LNG-FSRU) based on nuclear power has a reactor cabin, and a nuclear reactor is arranged in the reactor cabin. The nuclear reactor adopts a conventional pressurized water reactor, and the pressurized water reactor passes The pipeline is connected with the steam generator and the main circulation pump in sequence, and the main circulation pump flows back to the pressurized water reactor to form the first circulation network. A voltage stabilizer is arranged between them, and the voltage stabilizer is used to prevent the equipment from being damaged due to the high pressure in the first circulation network and the boiling of the coolant caused by the low pressure.

[0031] The steam generator is sequentially connected with the throttling device, the pump turbine, the first water glycol heater, the seawater condenser, the condensate pump, the warm water tank heating, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com