Electromagnetic coupling vibration test system and control strategy during high-speed rotation of direct-drive hub motor

An in-wheel motor and electromagnetic coupling technology, which is applied in the field of direct-drive in-wheel motor controller test systems and control strategies, can solve problems such as reduced vehicle ride comfort and vehicle ride comfort affecting occupant comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] In this embodiment, the specific implementation process includes the following steps:

[0041] Step S1: Set the parameter information of the drum, obtain the required torque, input the speed and torque, and send a control command through the vehicle controller to complete the process of starting the vehicle rotation.

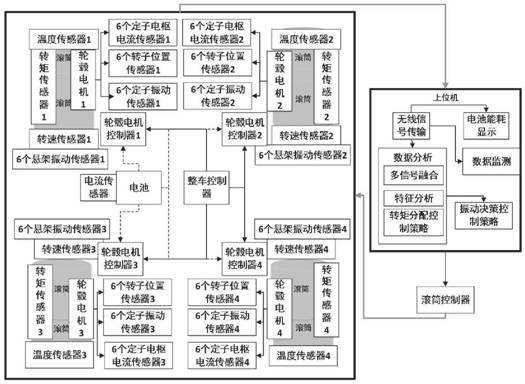

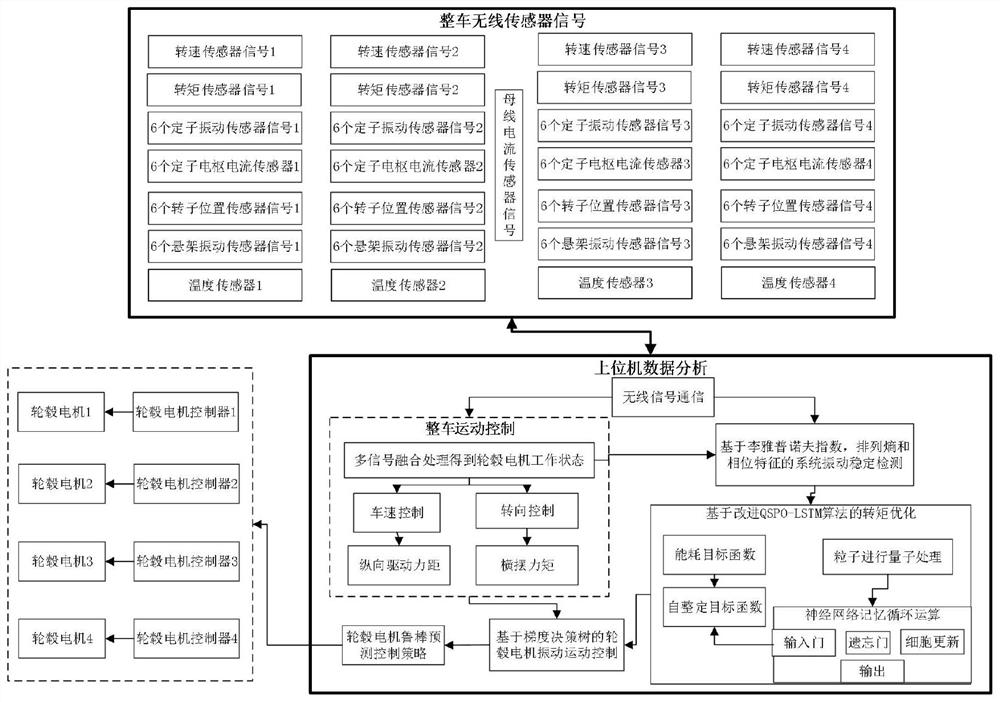

[0042] Step S2: The sensor module detects the working status of the wheel drive in real time. On the one hand, the information is transmitted to the acquisition system through wireless Bluetooth, and then to the data analysis system; on the other hand, the information of the wheel motor is fed back to the wheel motor controller. Control the rotation of the hub motor.

[0043] Step S3: The vibration stabilization layer in the data analysis system processes and calculates the fusion signal. The data is randomly sampled, the phase characteristics are obtained through the time series diagram, and the Lyapunov index and permutation entropy are calculated.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com