Model Predictive Control Method of Permanent Magnet Synchronous Motor Based on Dead Zone Effect

A permanent magnet synchronous motor, model predictive control technology, applied in the field of control, can solve problems such as large torque ripple, dead zone and overall modeling of the motor, and failure to realize the change of the control signal state and control performance requirements of the inverter. Achieve the effects of reducing loss, improving torque control effect, and reducing internal power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

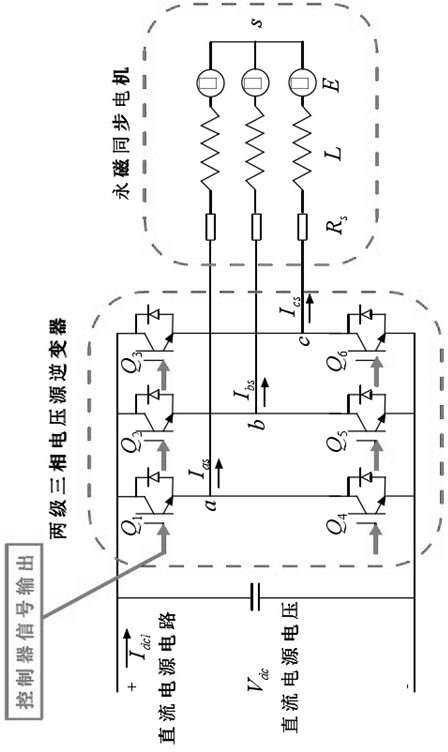

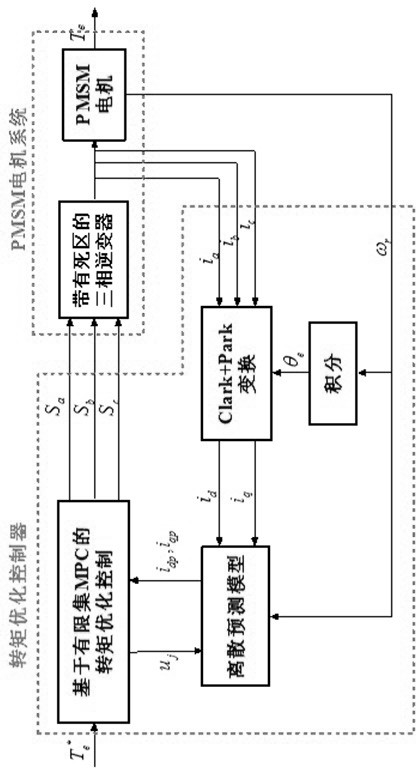

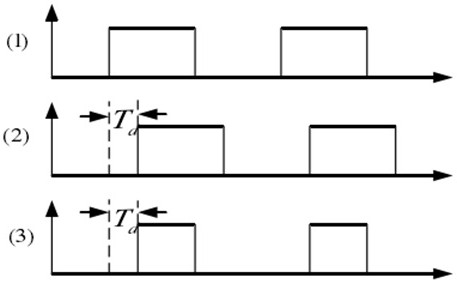

[0058] The present invention relates to a model predictive control method for permanent magnet synchronous motors considering the dead zone effect. Discrete optimal control of the switch and compensation for the influence of the dead zone effect of the inverter can improve the control performance of the permanent magnet synchronous motor, reduce torque ripple, and reduce losses.

[0059] The permanent magnet synchronous motor control system based on model predictive control designed by the present invention can well solve the above three problems. The present invention uses predictive control in the discrete optimization control of the inverter, predicts the future behavior information according to the status of the inverter and the dynamic characteristics of the load, directly optimizes the discrete switch variables, and realizes the drive control of the inverter. Due to the number of discrete switch variables finite, hence the name Finite Set Model Predictive Control (FCS-MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com