Tail end wire stripping machine for high-power transmission cable

A technology for conveying cables and stripping machines, which is used in cable installation, equipment for dismantling/armored cables, cable installation devices, etc. and other problems, to achieve the effect of convenient cutting of insulating protective layer, simple peeling and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

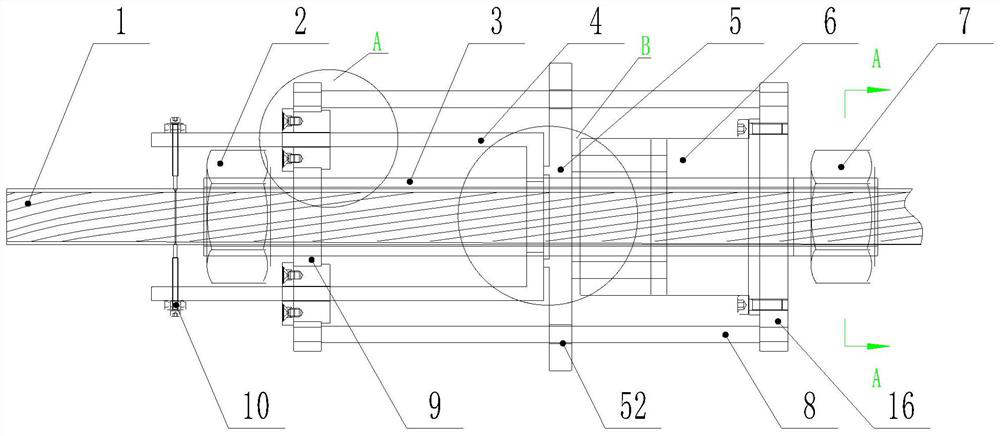

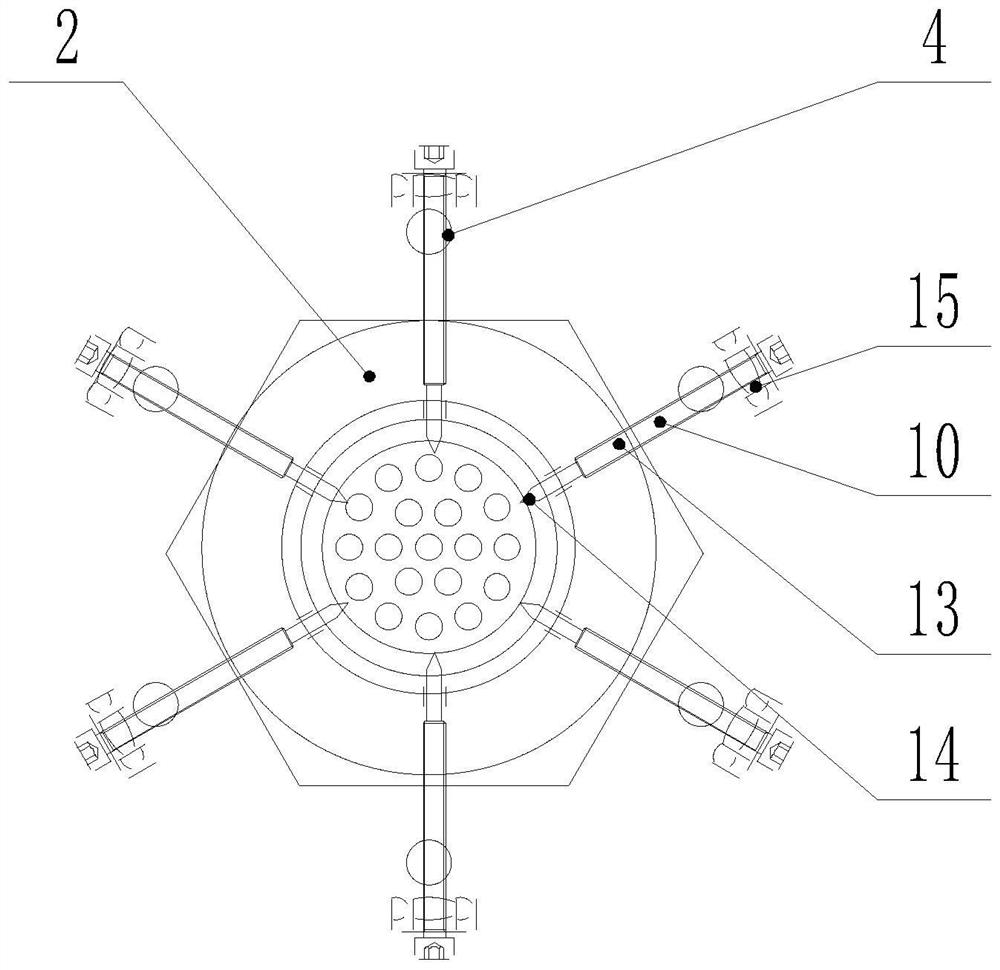

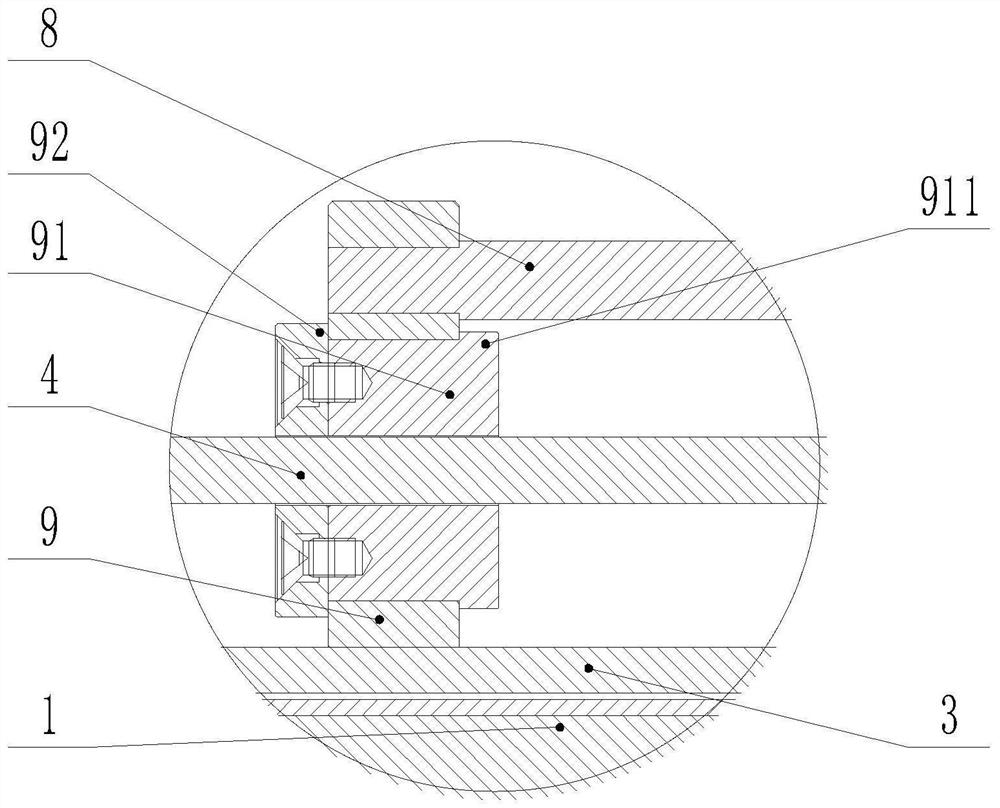

[0025] Such as Figure 1-7 As shown, the terminal stripping machine of a high-power transmission cable according to the present invention includes a fixed sleeve 3, and the two ends of the fixed sleeve 3 are processed with threads, and grooves 31 are processed along the radial direction at the thread. There are lock nut A2 and lock nut B7, through the screwing of lock nut A2 and lock nut B7, the thread is tightened at the groove 31, and the cable 1 is positioned; the positioning plate is fixedly installed on the left side of the fixing sleeve 3 A9, the positioning plate B16 is fixedly installed on the right side, and the positioning plate A9 and the positioning plate B16 are connected by a fixed rod 8. The fixing sleeve 3 is tubular, and the diameter of the inner hole is larger than that of the cable 1. A groove 31 is processed on the outer surface of the fixing sleeve 3. The shape of the groove 31 is helical, and the shape of the helix is consistent with the winding rule of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com