Performance optimization method of water electrolysis hydrogen production system suitable for volatility input

A technology of a hydrogen production system and an optimization method, applied in the field of clean energy, can solve problems such as the inability to realize the performance optimization of the electrolysis water hydrogen production system, and achieve the effect of optimal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

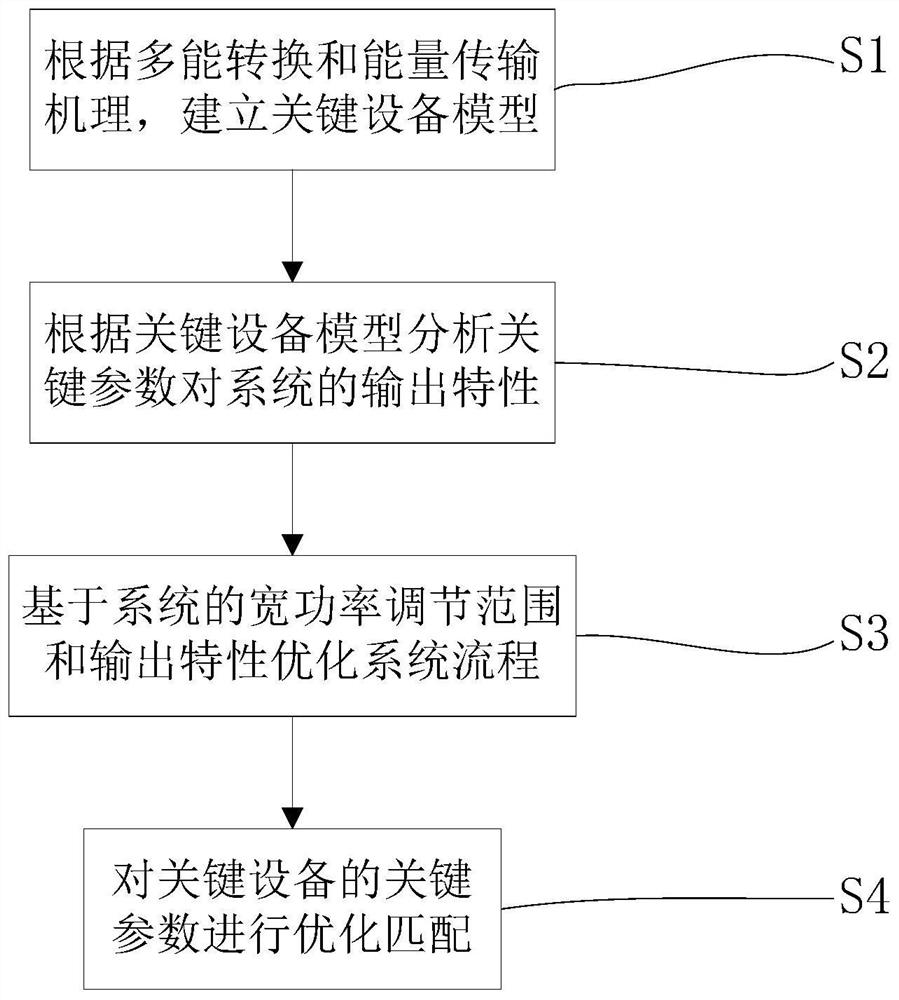

[0079] like figure 1 As shown, a performance optimization method for electrolyzed water hydrogen production system suitable for fluctuating input includes the following steps:

[0080] S1: According to the multi-energy conversion and energy transmission mechanism, establish the key equipment model;

[0081] S2: Analyze the output characteristics of key parameters to the system according to the key equipment model;

[0082] S3: Optimize the system process based on the wide power adjustment range and output characteristics of the system;

[0083] S4: Optimize and match key parameters of key equipment.

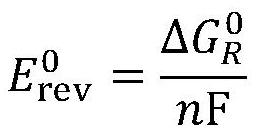

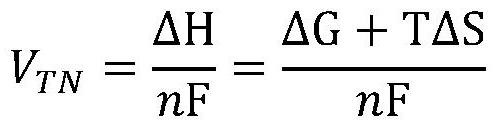

[0084] Step S1 establishes a simulation model of the proton exchange membrane electrolysis water hydrogen production system based on the mass balance equation, the energy balance equation and the electrochemical reaction equation by analyzing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com