Elevator energy-absorbing buffer structure, integrated elevator car frame and preparation method thereof

A buffer structure, elevator car technology, applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of long construction time, complex elevator buffer structure, water accumulation in elevator pits, etc., and achieves convenient production. , The effect of reducing own weight and increasing load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

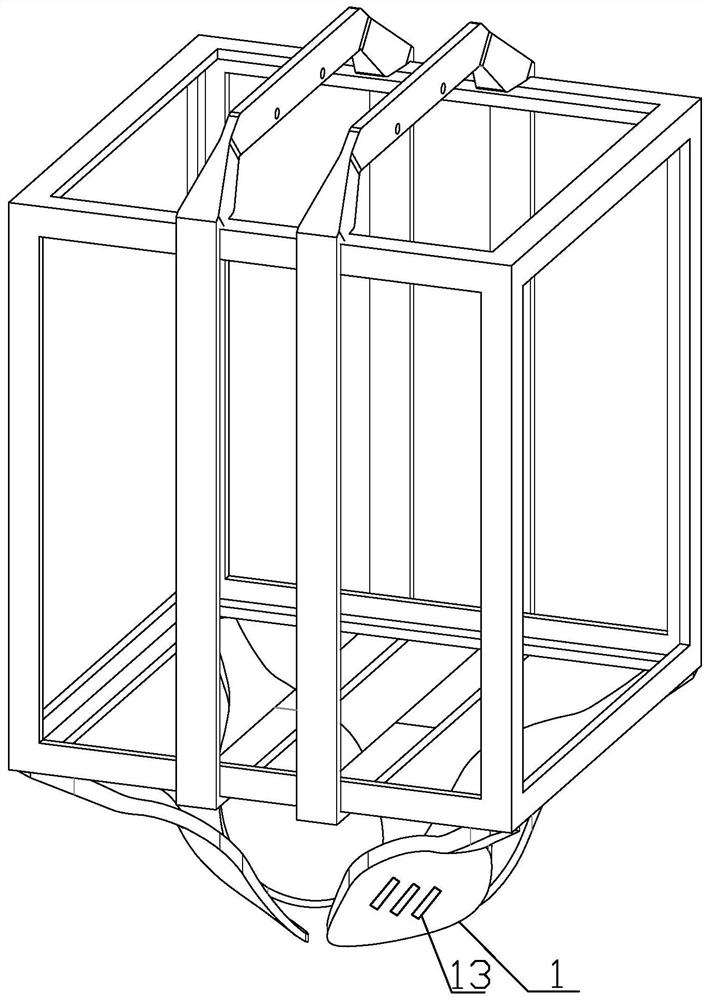

[0052] An energy-absorbing buffer structure for an elevator, comprising several curved shrapnels 1, the several curved shrapnels 1 are evenly distributed and fixedly arranged around the bottom surface of an elevator car, and the central axis of each said curved shrapnel 1 starts from the bottom edge of the car. The edge to the edge of the curved elastic piece 1 away from the bottom edge of the car is in an 'S' shape, and the several curved elastic pieces 1 extend downward from the bottom edge of the car to the central axis of the car and gather together.

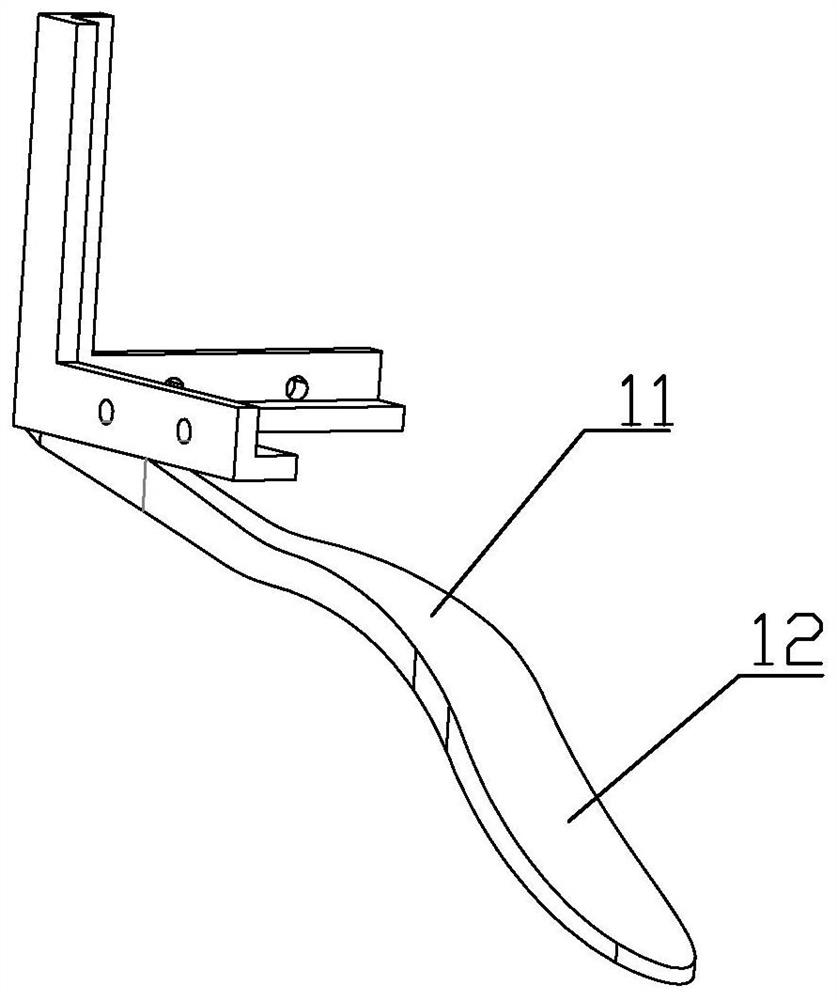

[0053] Further, the curved shrapnel 1 includes an arc surface I11 and an arc surface II12, the arc surface I11 is fixedly connected to the bottom edge of the elevator car, the arc surface I11 protrudes toward the central axis of the elevator car, and the arc surface II12 Contrary to the convex direction of the arc surface I11, the arc surface II12 is integrally formed with the arc surface I11.

[0054] Further, the model for...

specific Embodiment approach 2

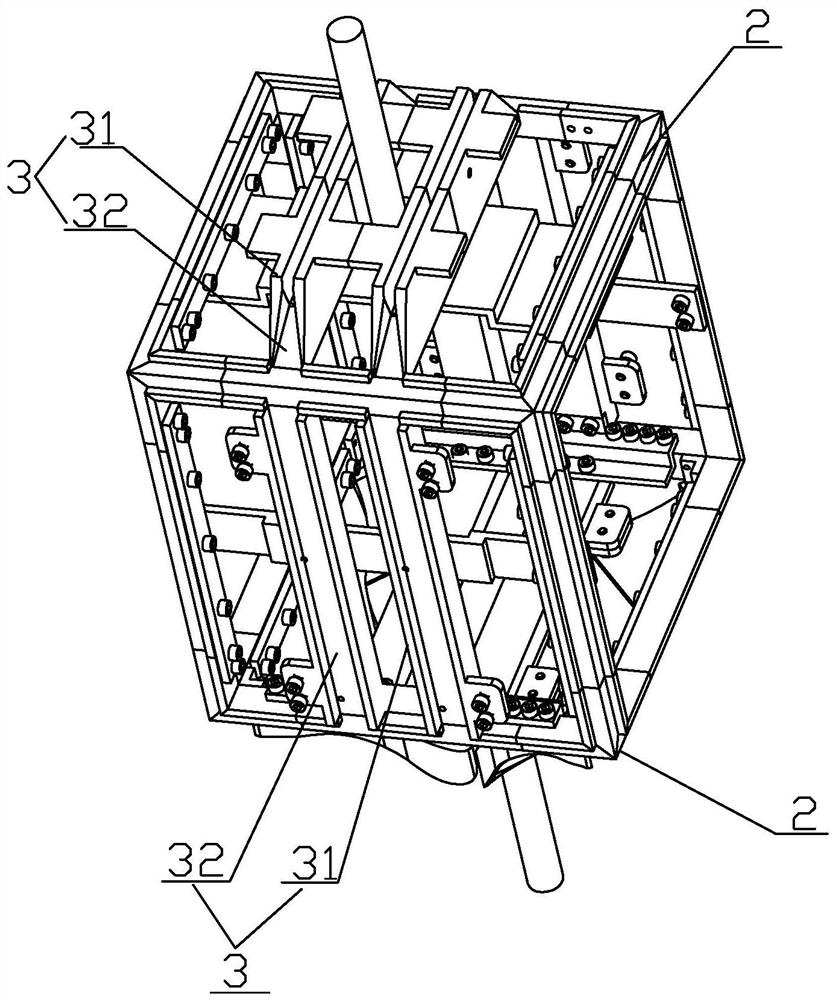

[0066] An elevator car cage frame includes an elevator car frame 2 and an elevator energy-absorbing buffer structure as described in Embodiment 1, and the elevator energy-absorbing buffer structure is fixedly arranged at the bottom edge of the elevator car frame 2 .

specific Embodiment approach 3

[0067] A method for preparing the elevator car cage described in Embodiment 2, comprising the following steps:

[0068] Step 1, making the elevator car frame blank: the elevator car frame tooling inner mold 2 is a cube frame, and the cross-section of each prism forming the cube frame is the shape of three steps. Wrap several layers of continuous fiber narrow strips on the surface and plane to obtain the elevator car frame blank. The cross-section of each prism that makes up the elevator car frame blank is 'L'-shaped. The advantages of the 'L'-shaped prism are strength. The second is to facilitate the subsequent placement of the wall panels of the elevator car;

[0069] Step 2. Making the lifting bracket blank: the upper surface, the lower surface and the middle part of the two side walls of the elevator car frame tooling inner mold 2 are fixedly provided with two mutually parallel baffles 31, forming two groups of mutually parallel lifting brackets. The inner mold 3 of the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com