Stator assembly and motor with same

A stator winding and stator technology, applied to the shape/style/structure of electric components, winding conductors, windings, etc., can solve problems such as unbalanced current, difficult manufacturing process, and high production cost, so as to reduce solder joints and reduce production costs. Difficulty and production cost, the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

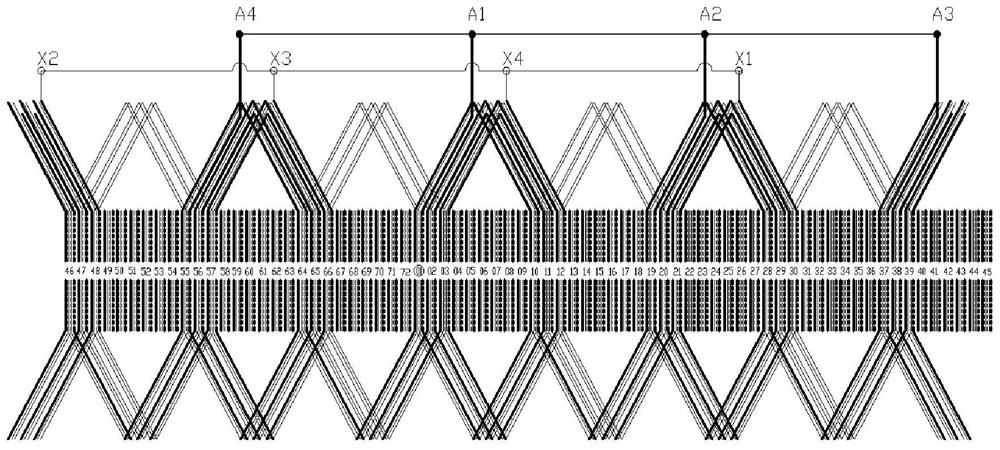

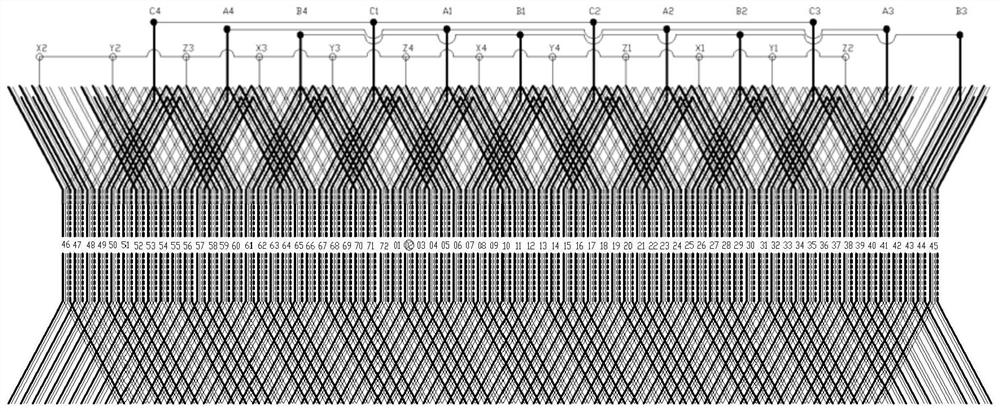

[0038] Refer below Figure 1-Figure 8 A stator assembly according to an embodiment of the invention is described.

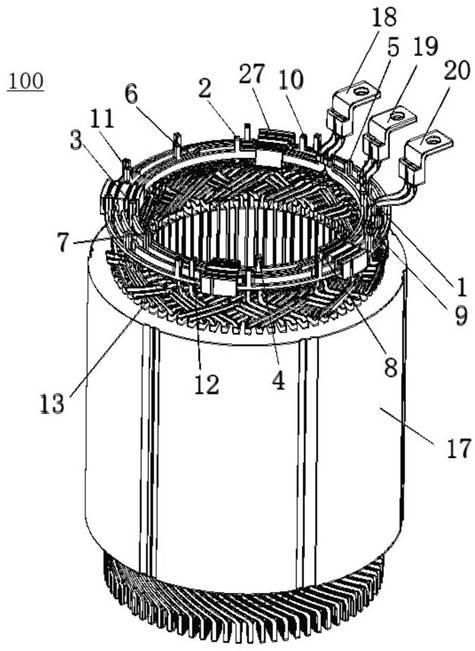

[0039] figure 1 It is a structural schematic diagram of a stator assembly according to an embodiment of the present invention, such as figure 1 As shown, the stator assembly 100 of the embodiment of the present invention includes a stator and stator windings.

[0040] Wherein, the stator includes a stator core 17 , Z coil slots 13 are distributed along the circumferential direction on the inner wall of the stator core 17 , and the Z coil slots 13 all extend along the radial direction of the stator core 17 . The coils of each phase winding are set in preset spans.

[0041]Among them, the stator winding includes a three-phase winding, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com