Tool and system for cleaning optical fiber drawing channel

A channel and optical fiber technology, which is applied in the tooling and system field of optical fiber drawing channel cleaning, can solve the problems of easy shaking of optical fiber drawing, easy dust pollution and other problems, and achieve the effect of uniform adsorption force, good convergence and collection, and enlarged range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

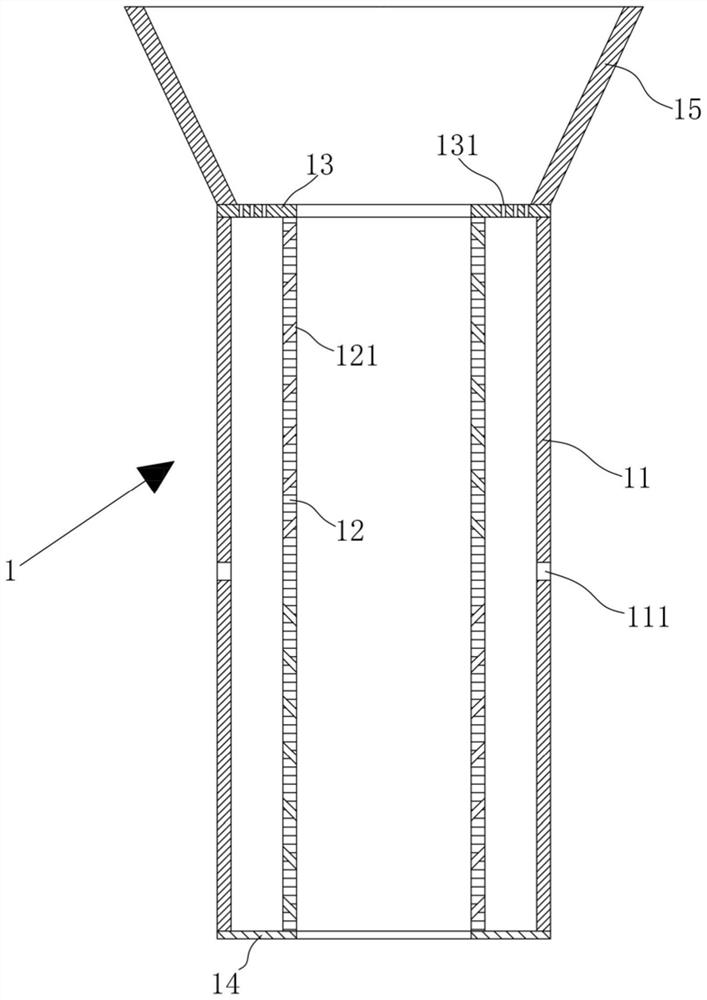

[0046] refer to figure 1 , this embodiment provides a tool for cleaning the optical fiber drawing channel, including an outer cylinder 11 , an inner cylinder 12 , an upper ring plate 13 and a lower ring plate 14 .

[0047] Wherein, the outer cylinder 11 is provided with at least two ports 111 , the ports 111 are suitable for externally connecting the negative pressure mechanism 3 , and all the ports 111 are evenly distributed along the circumference of the outer cylinder 11 . The main function of the interface 111 is to connect with the negative pressure mechanism 3 in use to form an air flow. The shape of the interface 111 is not limited here, and may be circular or square or other common shapes, depending on the shape of the joint of the negative pressure mechanism 3 . The arrangement form of the interface 111 can be only one circle in the axial direction of the outer cylinder 11, or two or more circles along the axial direction of the outer cylinder 11, but each circle mus...

Embodiment 2

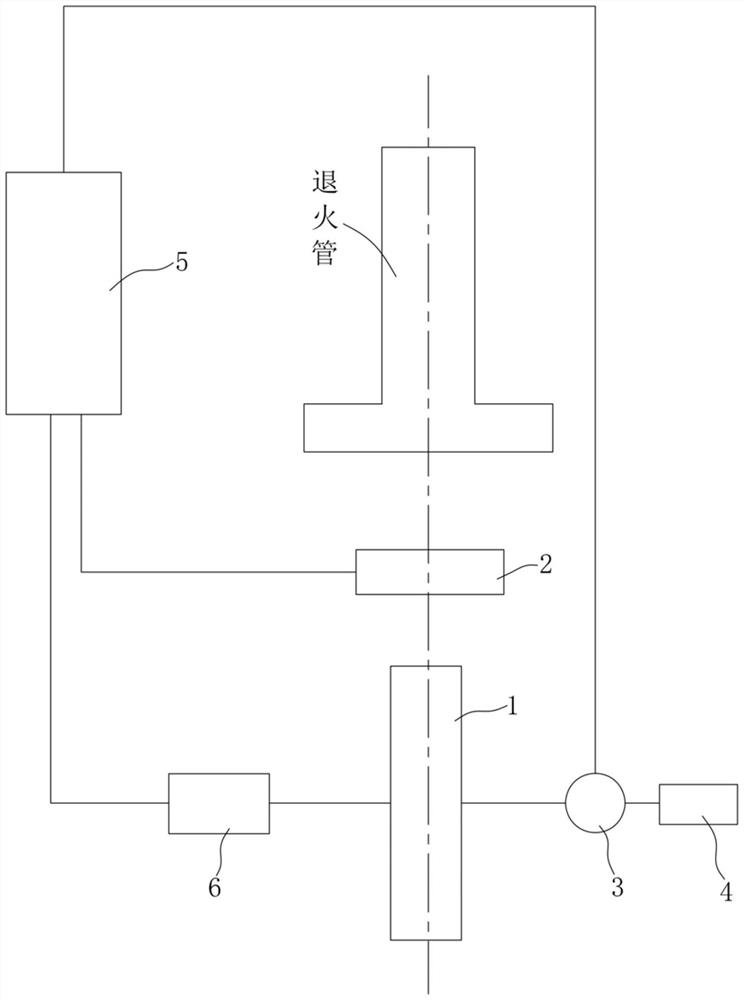

[0058] refer to figure 2 , this embodiment provides a system for cleaning the optical fiber drawing channel, including a wire diameter meter 2, a tooling 1, a negative pressure mechanism 3, a filter mechanism 4 and a controller 5.

[0059] Among them, the wire diameter meter 2 is a mature structure in the field, which is suitable for detecting the diameter of an optical fiber. It should be noted that, because it needs to cooperate with the controller 5, it is necessary to use the electronic wire diameter gauge 2 capable of sending signals.

[0060] Wherein, the tooling 1 adopts the structure as described in the first embodiment.

[0061] Wherein, the negative pressure mechanism 3 can adopt common structures such as a vacuum machine and an exhaust fan, and the negative pressure mechanism 3 is provided with an input port and an output port, and its input port is connected with the interface 111, so that a negative pressure is formed in the dust discharge channel, thereby remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com