Polystyrene production equipment

A polystyrene and equipment technology, applied in the field of polystyrene production equipment, can solve the problems of uneven heating of the slurry, affecting the foaming effect, material damage, etc., to improve the uniform effect of heating and foaming, and improve the heating and foaming. effect, the effect of improving the heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

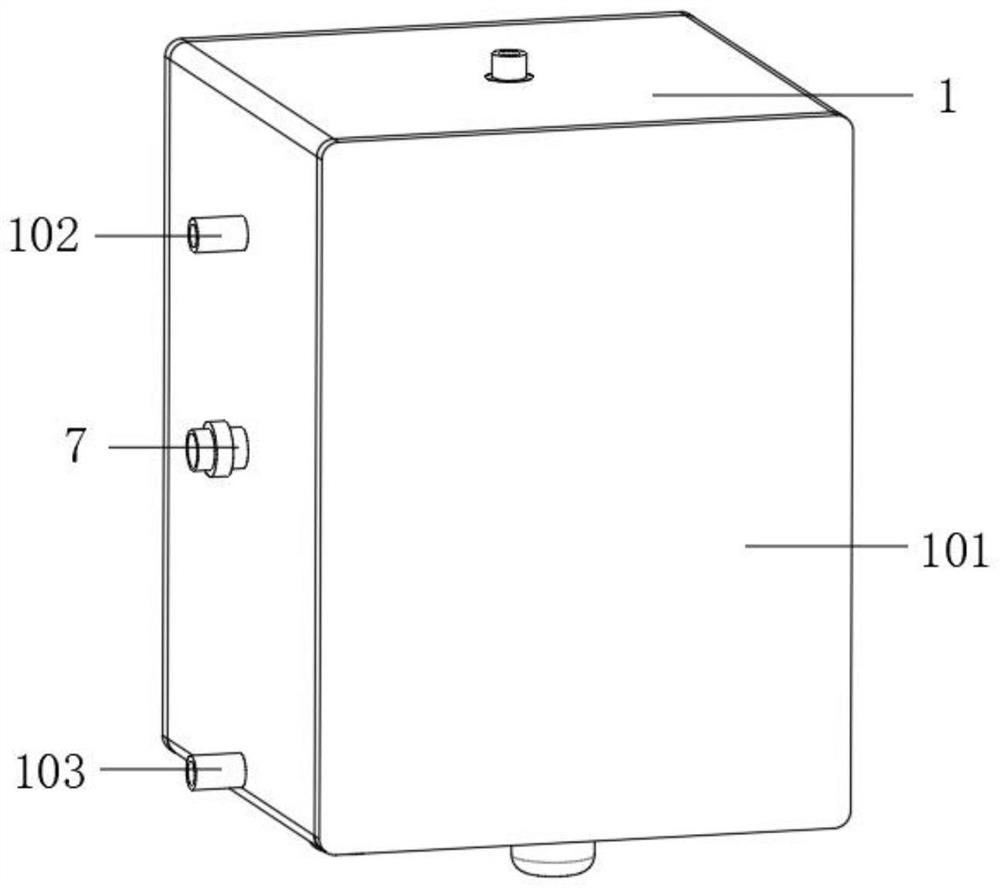

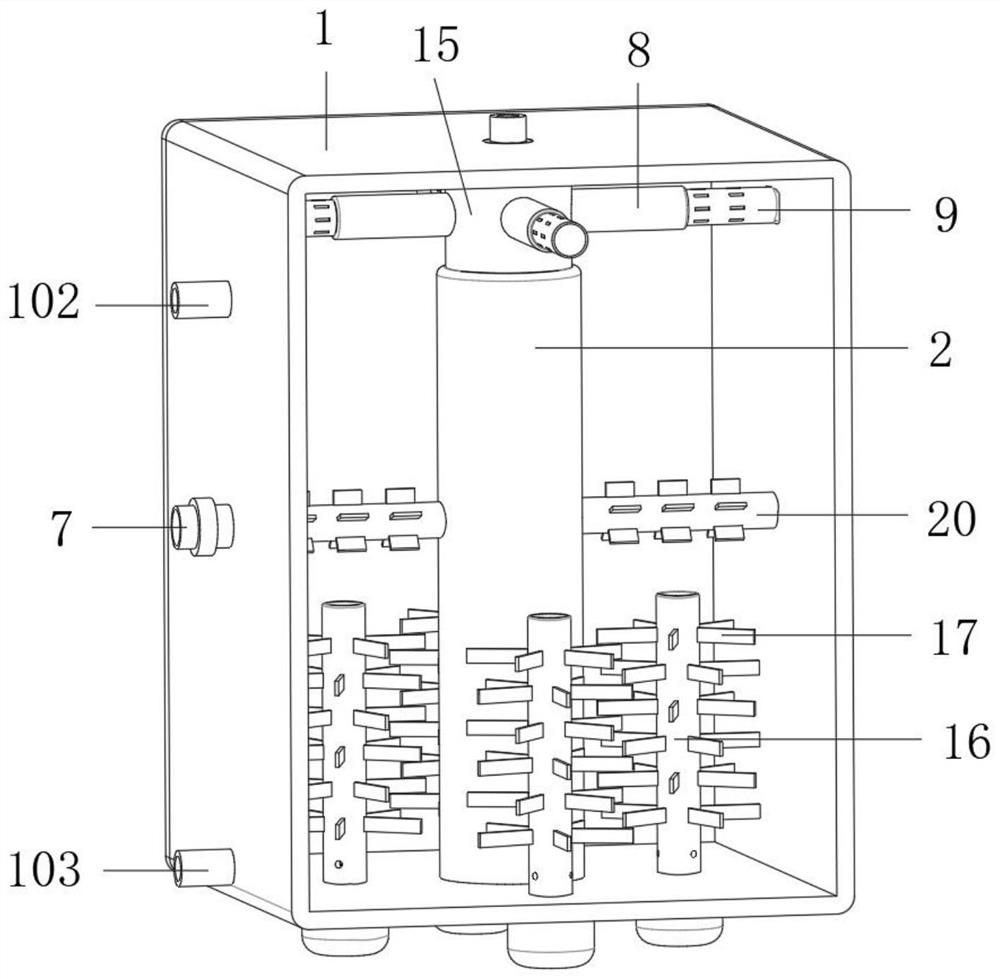

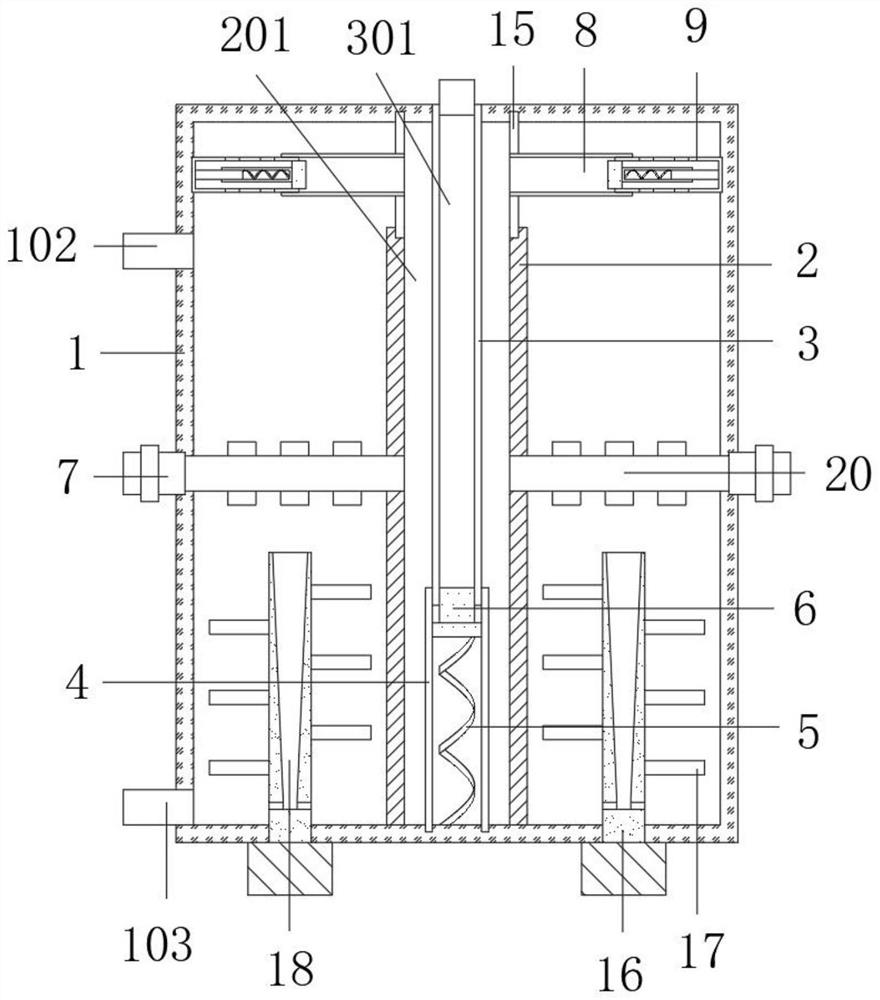

[0030] refer to Figure 1-Figure 3 , a kind of polystyrene production equipment, comprises foam box 1, and the both ends of foam box 1 can be detachably connected with sealing cover 101, and the intermediate position between foam box 1 top and bottom inner wall is fixed with heat exchange tube 2, and the top and bottom ends of the heat exchange tube 2 are sealed with the inner wall of the foam box 1, the top inner wall of the foam box 1 is located at the center of the heat exchange tube 2, and a vent pipe 3 is fixed, and the top end of the vent pipe 3 is connected to There is an air intake pipe, and the air intake pipe feeds high-temperature steam into the air pipe 3, and the connecting net cylinder 4 is connected between the bottom end of the air pipe 3 and the inner wall of the bottom of the foaming box 1, and the inner wall of the bottom of the foaming box 1 is located at the bottom of the connecting net cylinder 4. The center position is fixed with a vertically placed firs...

Embodiment 2

[0036] Embodiment 2 includes all structures and methods of Embodiment 1, with reference to image 3 with Image 6 , a kind of polystyrene production equipment, also includes, the inner wall of the bottom of the foaming box 1 is rotatably connected with a plurality of vertically placed stirring rods 16, and the plurality of stirring rods 16 are ring-shaped along the outer circumference of the heat exchange tube 2 Distribution, the bottom end of the stirring rod 16 is connected with a drive motor, the outer wall of the stirring rod 16 is fixed with a plurality of stirring blades 17, the top of the stirring rod 16 is provided with a drainage cavity 18, and the vertical section of the drainage cavity 18 is set in a conical structure. , the cross-sectional area of the drainage chamber 18 gradually decreases from top to bottom, and the bottom end of the inner wall of the drainage chamber 18 is provided with a plurality of horizontally arranged perforations 1801. In actual heating ...

Embodiment 3

[0040] Embodiment 3 includes all structures and methods of embodiment 1 and embodiment 2, with reference to figure 2 with Figure 8 , a polystyrene production equipment, also includes two outlet pipes 7, and the two outlet pipes 7 are respectively fixed on the inner walls of both sides of the foam box 1, and the outlet pipe 7 is provided with an initial outward facing A one-way valve, a horizontal connecting pipe 20 is connected between the air outlet pipe 7 and the heat exchange pipe 2, and the two ends of the communication pipe 20 are respectively connected to the heat exchange pipe 2 and the air outlet pipe 7 through bearing rotation, and the communication pipe 20 A plurality of heat exchange fins 21 are penetrated and fixed on the outer wall of the heat exchange fins 21. The end of the heat exchange fins 21 away from the connecting pipe 20 is provided with a flow diversion groove 22 that penetrates horizontally. The width of the flow diversion groove 22 gradually decrease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com