Anti-whiplash mechanism of automobile seat

A car seat, anti-whiplash technology, applied in vehicle seats, special positions of vehicles, vehicle parts, etc., can solve the problems of high manufacturing requirements, high fuel consumption of the whole vehicle, high cost, and achieve low manufacturing requirements, light weight, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

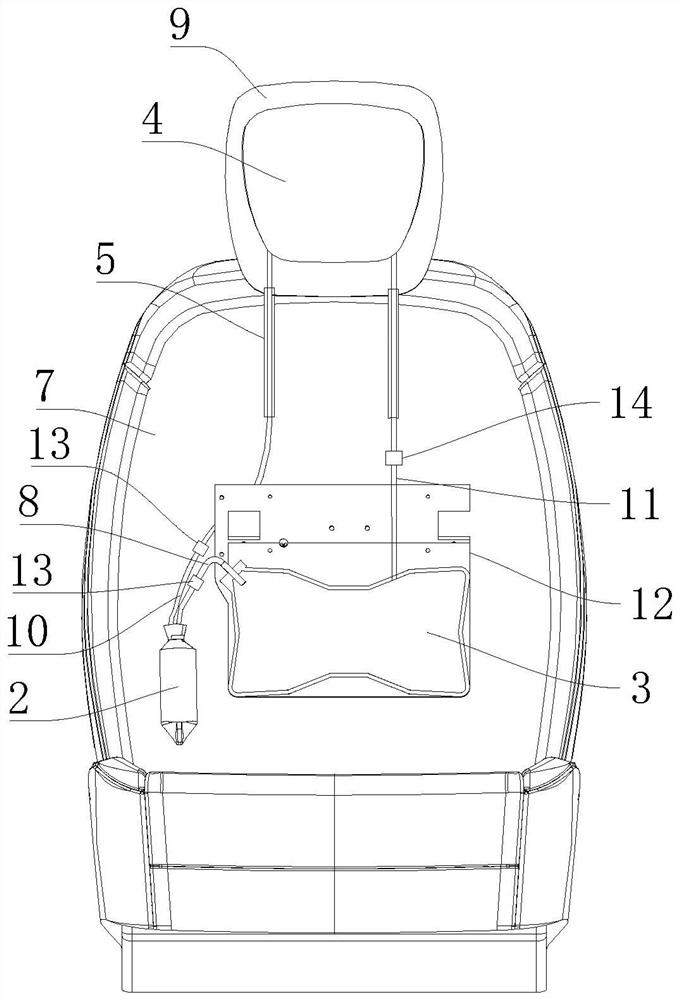

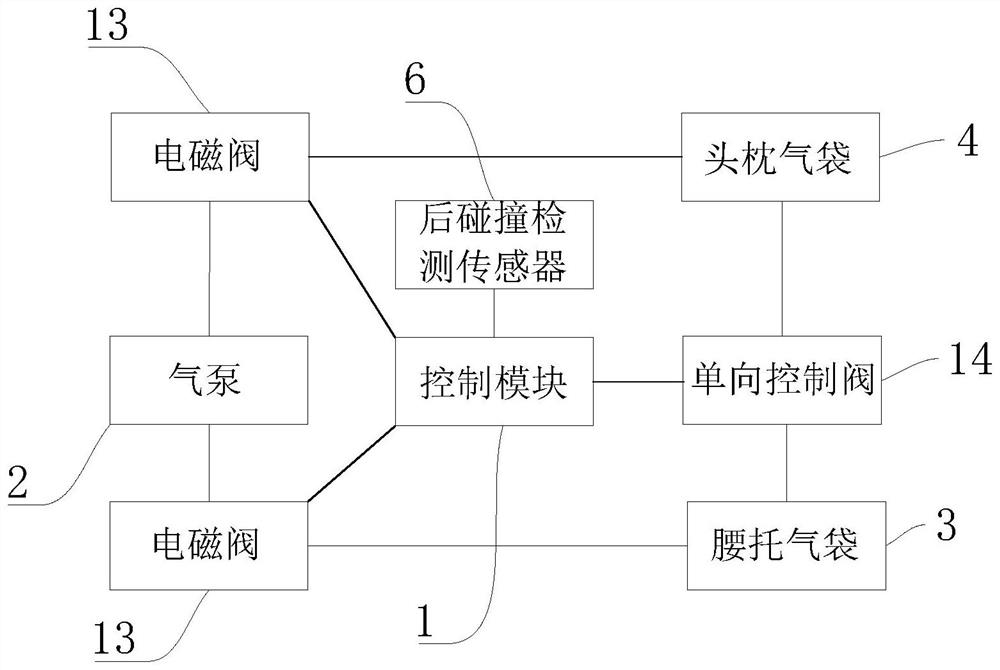

[0018] An anti-whiplash mechanism for a car seat, comprising a control module 1, an air pump 2, a lumbar support air bag 3, a headrest air bag 4, a hollow headrest rod 5 and a rear collision detection sensor 6; the control module 1 is arranged on the vehicle body In the central control large screen, the air pump 2 and the lumbar support air bag 3 are installed in the seat back 7; the air pump 2 and the lumbar support air bag 3 are connected through the first air pipe 8; the headrest air bag 4 Installed in the seat headrest 9; the headrest air bag 4 is connected with the air pump 2 through the second air pipe 10; and the lumbar support air bag 3 and the headrest air bag 4 are passed through the third air pipe 11 connection; two sides of the lower part of the seat headrest 9 are respectively provided with two hollow headrest rods 5; the seat headrest 9 is installed on the seat back 7 through the hollow headrest rods 5 The top of the vehicle; the rear collision detection sensor 6...

Embodiment 2

[0020] An anti-whiplash mechanism for a car seat, comprising a control module 1, an air pump 2, a lumbar support air bag 3, a headrest air bag 4, a hollow headrest rod 5 and a rear collision detection sensor 6; the control module 1 is arranged on the vehicle body In the central control large screen, the air pump 2 and the lumbar support air bag 3 are installed in the seat back 7; the air pump 2 and the lumbar support air bag 3 are connected through the first air pipe 8; the headrest air bag 4 Installed in the seat headrest 9; the headrest air bag 4 is connected with the air pump 2 through the second air pipe 10; and the lumbar support air bag 3 and the headrest air bag 4 are passed through the third air pipe 11 connection; two sides of the lower part of the seat headrest 9 are respectively provided with two hollow headrest rods 5; the seat headrest 9 is installed on the seat back 7 through the hollow headrest rods 5 The top of the vehicle; the rear collision detection sensor 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com