High-modulus hot-melt prepreg and preparation method thereof

A prepreg and high-modulus technology, applied in the field of high-modulus hot-melt prepreg and its preparation, can solve the problems of substandard prepreg apparent quality, a large number of hairs, broken wires, loss of mechanical properties, etc., and achieve smoothness Good performance and quality stability, reduced fiber modulus, and improved strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the hot-melt resin matrix is selected from epoxy resin, the high-modulus fiber is selected from M40X carbon fiber, and the modulus is higher than 380GPa.

[0034] (1) Adhesive film preparation: use the coating process to make epoxy resin into the upper and lower adhesive films. The coating film parameters are: coating film temperature 60-80 ℃, coating film speed 5-15m / min, and the surface density is 18-22g / m 2 film.

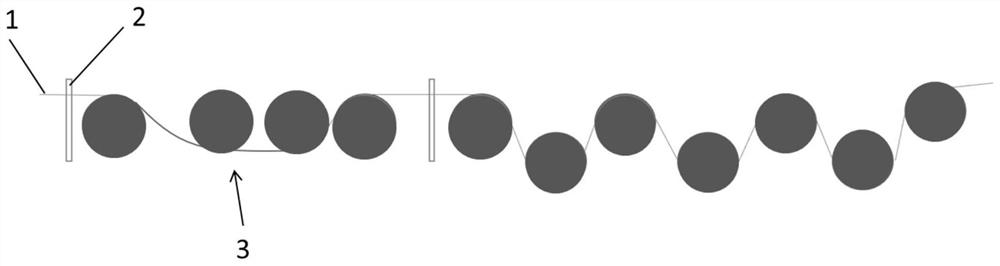

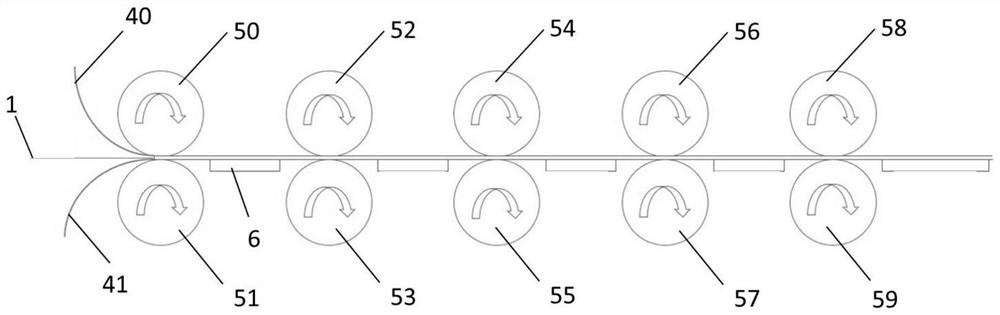

[0035] (2) Yarn threading and spreading of high-modulus fibers: fully unfold and flatten the M40X carbon fibers through threading and spreading; ≤60°, the angle is adjusted by the position of the creel and the position of the fiber hanging), to reduce the friction between it and the equipment parts, so that the M40X carbon fiber does not appear hair balls and broken filaments during the yarn threading process; secondly, if figure 1 As shown, the high-modulus fiber 1 (M40X carbon fiber) is made to pass through several groups of spre...

Embodiment 2

[0039] In this embodiment, the hot-melt resin matrix is selected from epoxy resin, the high-modulus fiber is selected from M55J carbon fiber, and the modulus is higher than 540GPa.

[0040] (1) Film preparation: use the coating process to make epoxy resin into the upper and lower film, the film parameters are: film temperature 60-80 ℃, film speed 5-15m / min, and the surface density is 23-29g / m 2 film.

[0041] (2) Yarn threading and spreading of high-modulus fibers: fully unfold and flatten the M55J carbon fibers through threading and spreading. ≤45°, the angle is adjusted by the placement position of the creel and the yarn hanging position of the fiber), to reduce the friction between it and the equipment parts, so that the M55J carbon fiber does not appear hairballs and broken filaments during the yarn threading process; secondly, the M55J carbon fiber is sequentially Through several groups of spreading combs and spreading rollers, in each set of spreading combs and spre...

Embodiment 3

[0045] In this embodiment, the hot-melt resin matrix is selected from cyanate resin, the high-modulus fiber is selected from M55J carbon fiber, and the modulus is higher than 540GPa.

[0046] (1) Preparation of adhesive film: Use cyanate resin to make upper and lower adhesive films by coating process. The coating parameters are: coating temperature 50-70°C, coating speed 5-15m / min, and the surface density is 38- 42g / m 2 film.

[0047] (2) Yarn threading and spreading of high-modulus fibers: fully unfold and flatten the M55J carbon fibers through threading and spreading. ≤45°, the angle is adjusted by the placement position of the creel and the yarn hanging position of the fiber), to reduce the friction between it and the equipment parts, so that the M55J carbon fiber does not appear hairballs and broken filaments during the yarn threading process; secondly, the M55J carbon fiber is sequentially Through several groups of spreading combs and spreading rollers, in each set of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com