Film preparation method for improving surface shape of optical element

A technology for film preparation and optical components, applied in optical components, optics, ion implantation and coating, etc., can solve the problems of inappropriate optical components, increase processes and costs, and achieve the effect of reducing adverse effects and improving surface shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Substrate treatment: Clean the substrate by ultrasonic method and dry it with isopropanol.

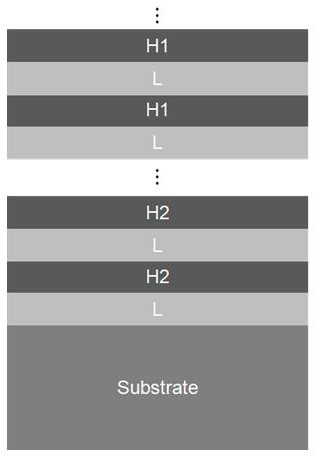

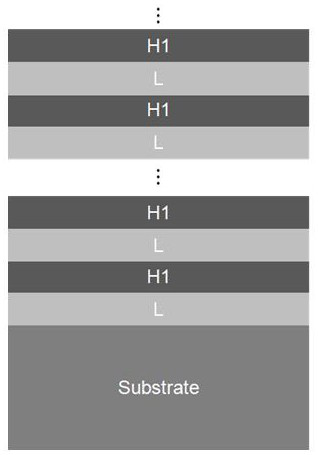

[0019] (2) Plating: use ion beam assisted deposition method, keep the temperature at 210°C for 40min, 1.8x10 -3 Under Pa vacuum degree, the following film system will be designed: 1.85L-1.98H2-1.99L-1.55H2-2.37L-1.39H2-2.32L-1.54H2-1.79L-0.74H2-0.99L-1.13H2-1.00L -0.79H2-1.06L-1.23H2-1.07L-0.81H2-0.92L-1.20H2-1.08L-0.90H1-0.88L-1.10H1-0.99L-0.95H1-0.99L-1.08H1-0.88L-0.93 H1-1.06L-1.11H1-0.90L-0.89H1-1.08L-1.09H1-0.89L-0.91H1-1.72L (H2 is hafnium oxide; H1 is tantalum pentoxide; L is silicon dioxide)

[0020] plated onto the substrate.

[0021] In this embodiment, the PV measured by the ZYGO interferometer is 0.12λ@633nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com