Control process of sulfide in sulfur bearing steel

A technology of sulfide and sulfur-containing steel, applied in the field of sulfide control technology in iron-based alloys, can solve problems such as unstable control and unsatisfactory effect, and achieve the effect of ensuring service performance and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment relates to the production of a steel product with a sulfur content of 0.015%, and its chemical composition is calculated by mass percentage:

[0032] 0.47%C, 0.25%Si, 1.05%Mn, 0.009%P, 0.015%S, 0.08%Cr, 0.02%Ni, 0.07%Cu, 0.015%Al, 0.07%V, 0.002%Nb, 0.015%Ti, 0.01% Mo, 0.012% N, the balance is Fe and unavoidable impurity elements.

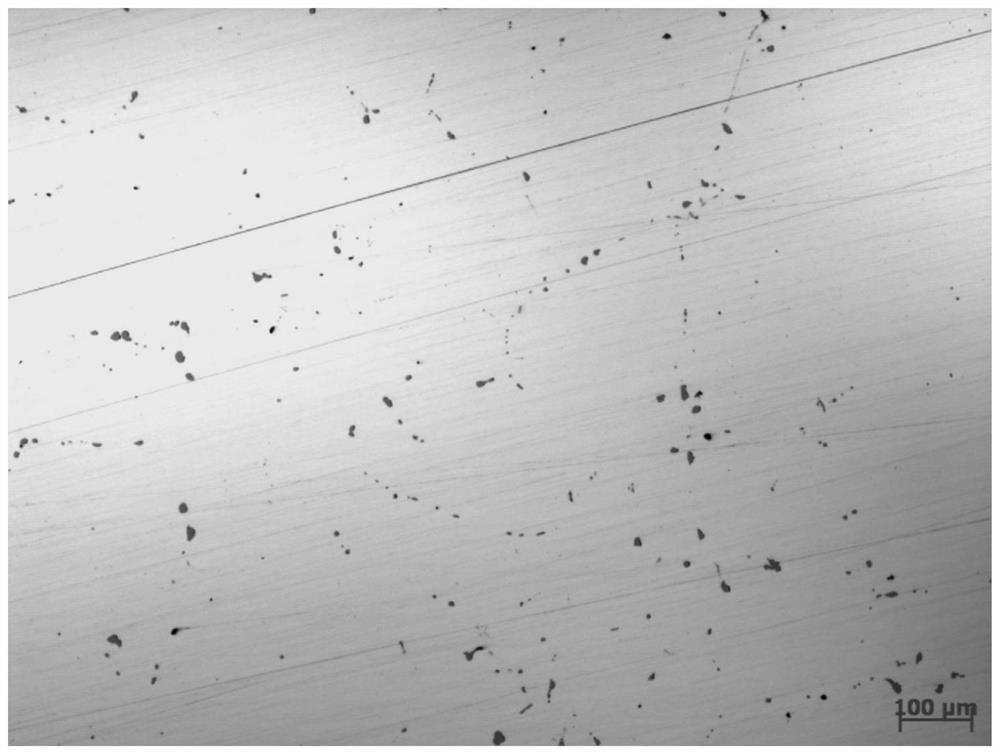

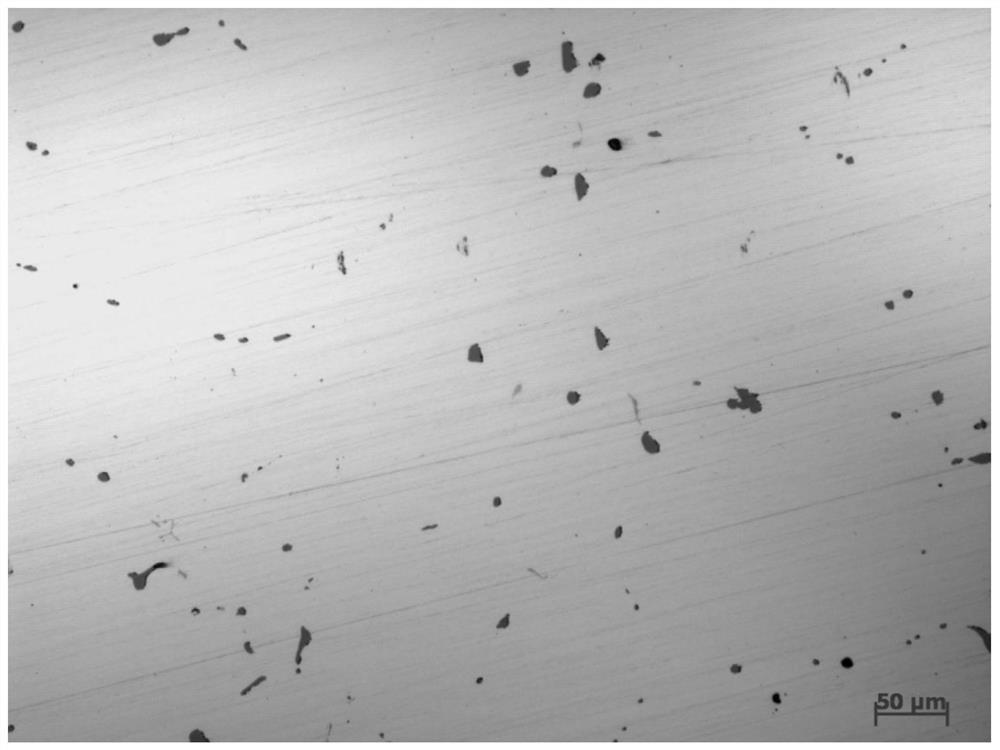

[0033] The manufacturing process of the 0.015% sulfur content steel product is: EAF electric furnace → LF refining furnace → VD vacuum refining furnace → molten steel denaturation treatment (adding 70m of composite cored wire whose main component is Fe-Mn-Ti-Zr, about 0.12Kg / tons of steel) → CCM continuous casting (M crystallizer + F end, M stirring frequency at 4Hz, stirring current at 100A, F stirring frequency at 20Hz, stirring current at 350A, where M is unidirectional rotation stirring, S+F is Forward / reverse two-way rotation stirring) EMS electromagnetic stirring continuous casting to obtain 300mm thick continuous ca...

Embodiment 2

[0039] This embodiment relates to the production of a steel product with a sulfur content of 0.060%, and its chemical composition is calculated by mass percentage as:

[0040] 0.38%C, 0.58%Si, 1.45%Mn, 0.012%P, 0.060%S, 0.16%Cr, 0.01%Ni, 0.01%Cu, 0.015%Al, 0.0059%Ti, 0.01%Mo, 0.018%N, balance It is Fe and inevitable impurity elements.

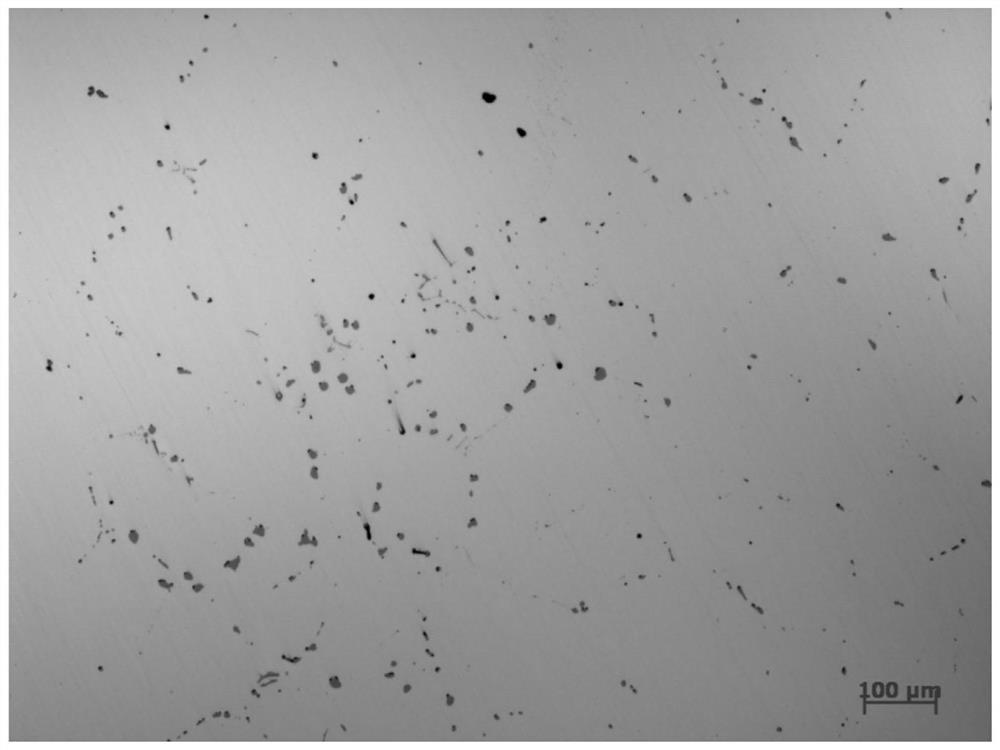

[0041]The manufacturing process of the steel product with 0.060% sulfur content is: BOF electric furnace → LF refining furnace → RH vacuum refining furnace → molten steel denaturation treatment (adding 200m of composite cored wire mainly composed of Fe-Mn-Ti-Zr, about 0.36Kg / ton Steel) → CCM continuous casting (M crystallizer + S casting stream + F end, M stirring frequency at 2.5Hz, stirring current at 135A, S stirring frequency at 8.5Hz, stirring current at 240A, F stirring frequency at 18Hz, stirring The current is 350A, where M is one-way rotation stirring, S+F is forward / reverse two-way rotation stirring) EMS electromagnetic stirring cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com