Electrically neutral nanofiltration membrane, preparation method and application of electrically neutral nanofiltration membrane in desalination of small molecular dye wastewater

A nanofiltration membrane, electrically neutral technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of interfering ion selectivity, limited charging control range, difficult to control ratio, etc. Separation performance, reduction of adverse effects, effect of good separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

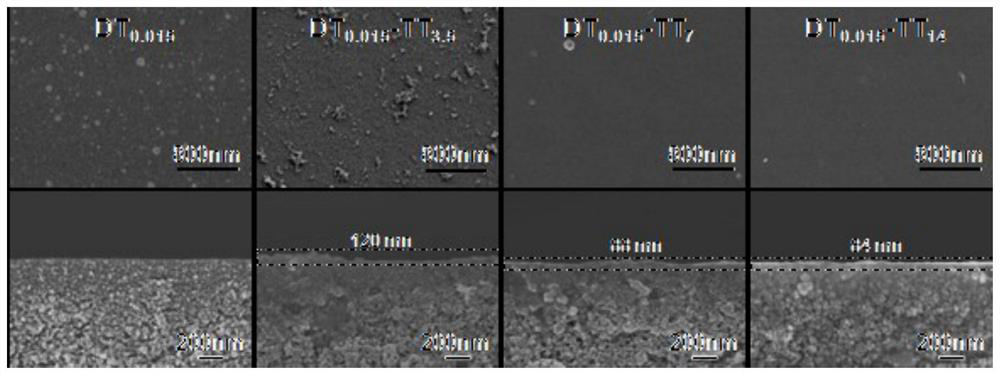

[0064] 1. Preparation of Flat Sheet Membrane

[0065] First, the polyimide polymer material is dissolved in an organic solvent, stirred for 24 hours to ensure full dissolution, and then left to defoam for 12 hours, and the solution is scraped out on the non-woven fabric with a scraper. Then, the membrane was prepared by phase inversion method and stored in deionized water.

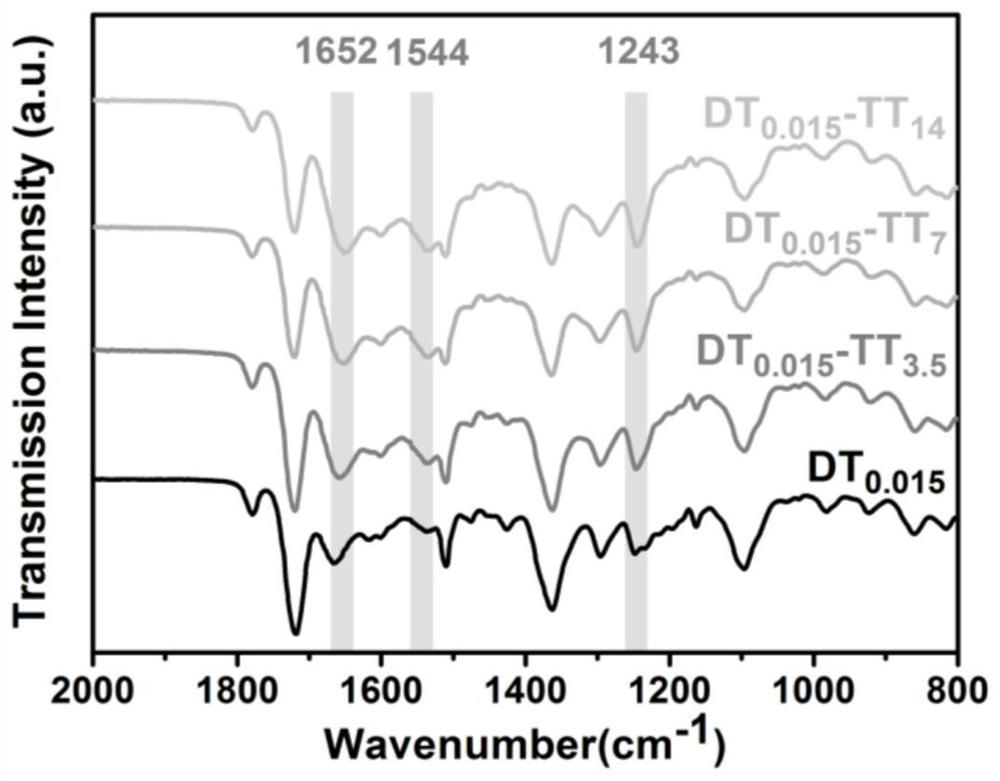

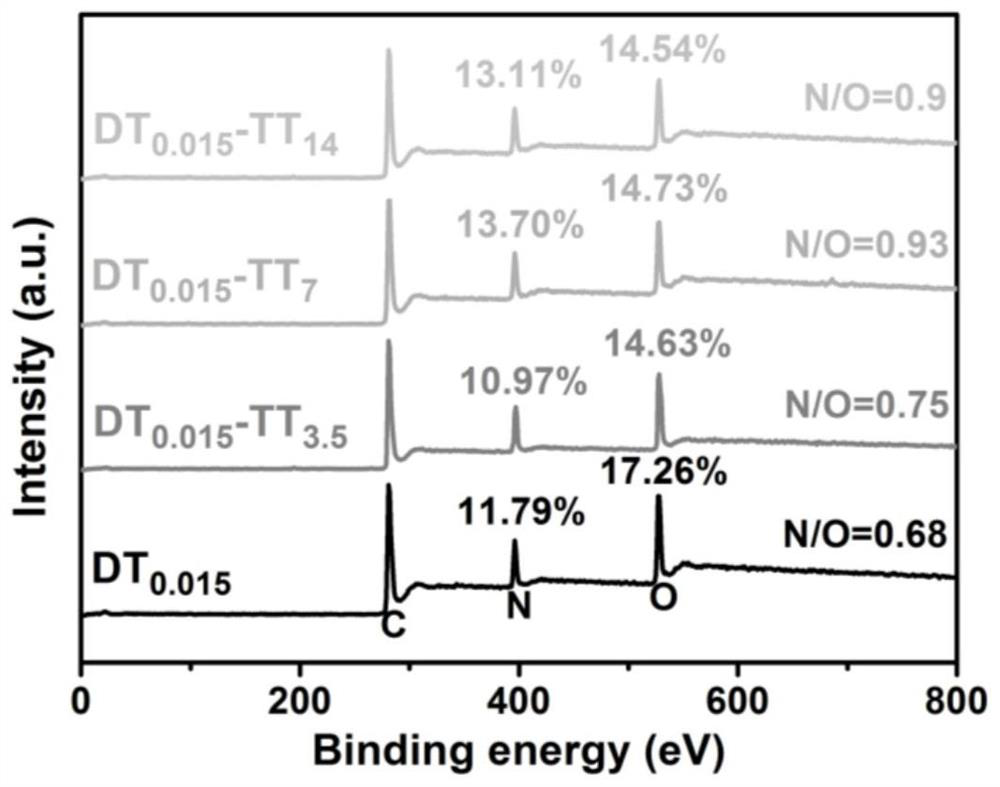

[0066] 2. Preparation of Selection Layer

[0067] Prepare DETA aqueous solution (0.01-0.06mol / L) of different concentrations, DETA is added in water to obtain interfacial polymerization aqueous phase; Trimellitic acid chloride (0.1wt%) is dissolved in n-hexane to obtain interfacial polymerization oil phase; Short-chain amine ( 0-14wt%) is dissolved in alcohol to obtain a modified phase. All three solutions were stirred thoroughly before use. First pour the water phase solution on the membrane, use a wipe paper to remove the excess water phase after two minutes, then pour into the organic phase, react fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com