Lead and bismuth corrosion resistant protection method for T91 and SIMP steel

A corrosion protection, T91 technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of oxide film dissolution, corrosion, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific technical solutions of the present invention are described in conjunction with the examples.

[0029] 1. Wire-cut T91 steel and SIMP steel substrates into several pieces of block-shaped small samples with a size of 20mm×10mm×5mm. After pretreatments such as grinding and derusting, dust and decontamination, and sandblasting, they are then placed in electric blast drying box for use

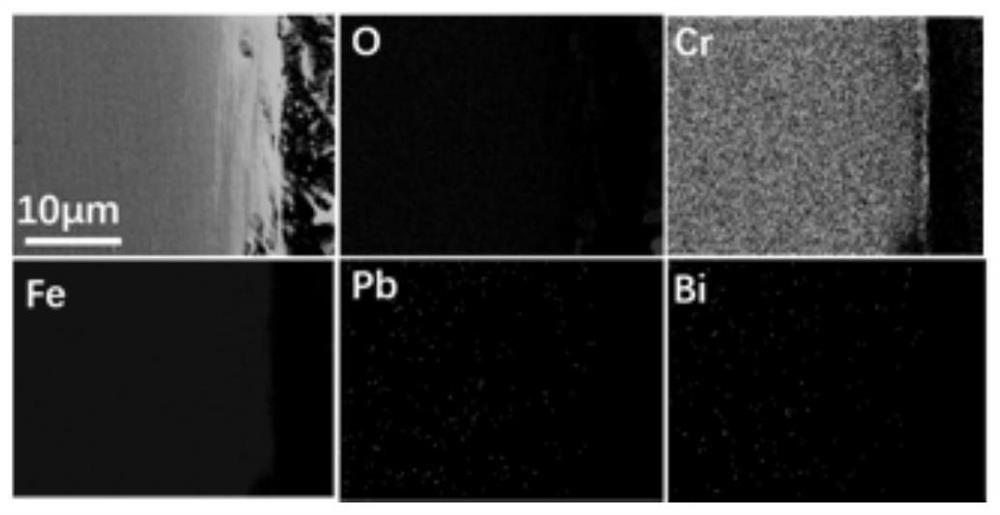

[0030] 2. Deposit a chromium coating on one side of the T91 steel and SIMP steel by magnetron sputtering, the thickness of the chromium coating is 2-3 microns.

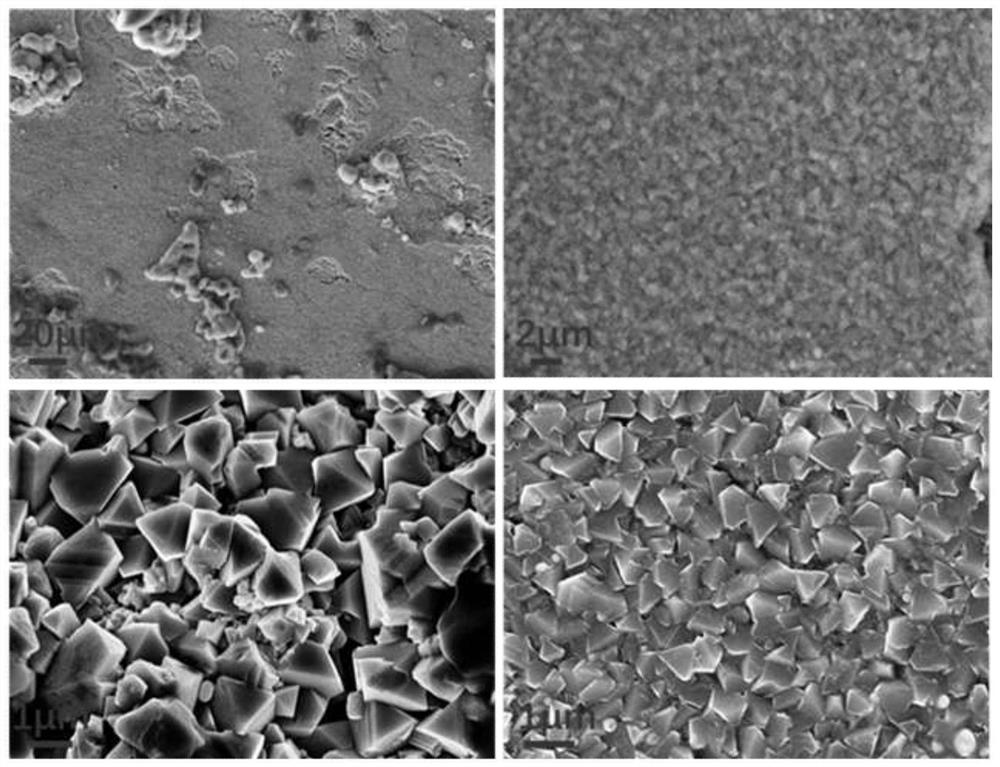

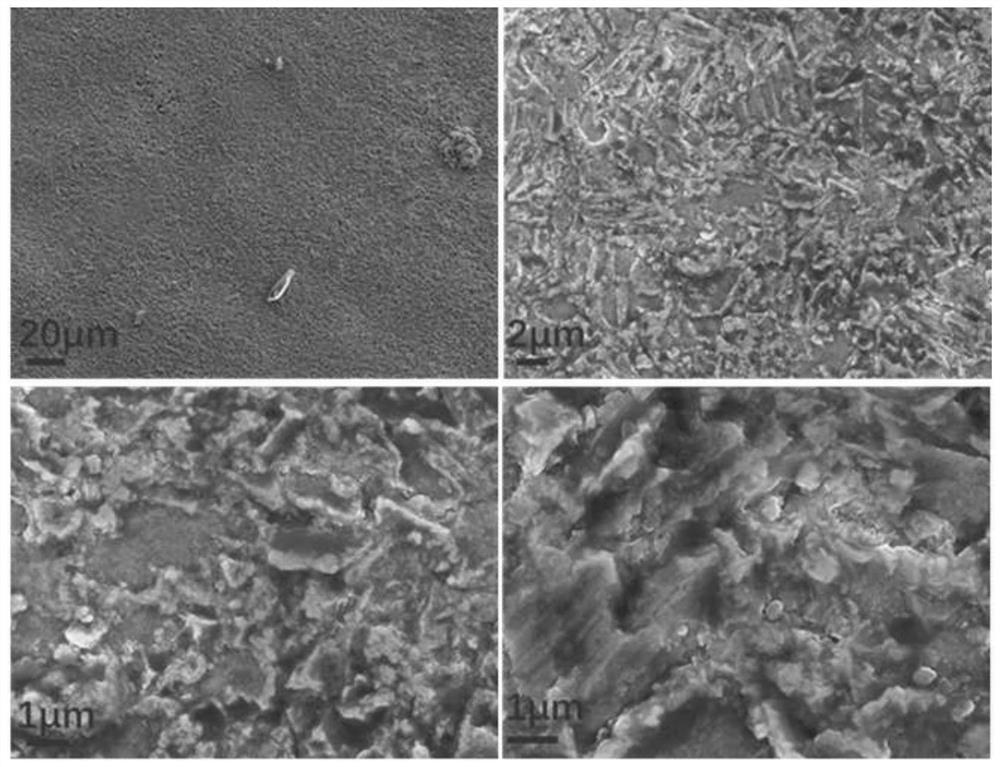

[0031] 3. The T91 steel and SIMP steel with chromium coating on the surface were corroded in liquid LBE at 700°C for 50 hours and 140 hours.

[0032] 4. After the corrosion experiment is completed, take out the sample, wash off the residual lead and bismuth on the surface of the sample with glycerin solution at 170°C, then wash the glycerol on the surface of the sample with hot water at 70°C, and finally clean the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com