Internal circulation transmission cold batch cylinder and use method thereof

A technology of internal circulation and cold stacking, which is applied to the processing of textile material drums, liquid/gas/steam open fabric processing, and textile material carrier processing, which can solve problems such as poor penetration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

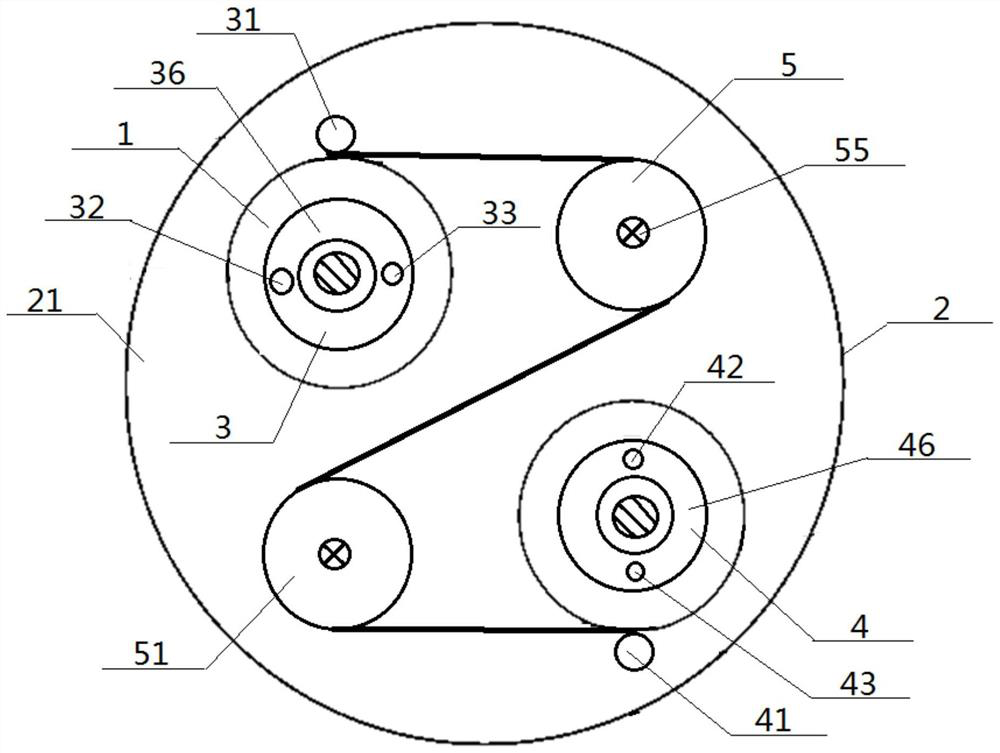

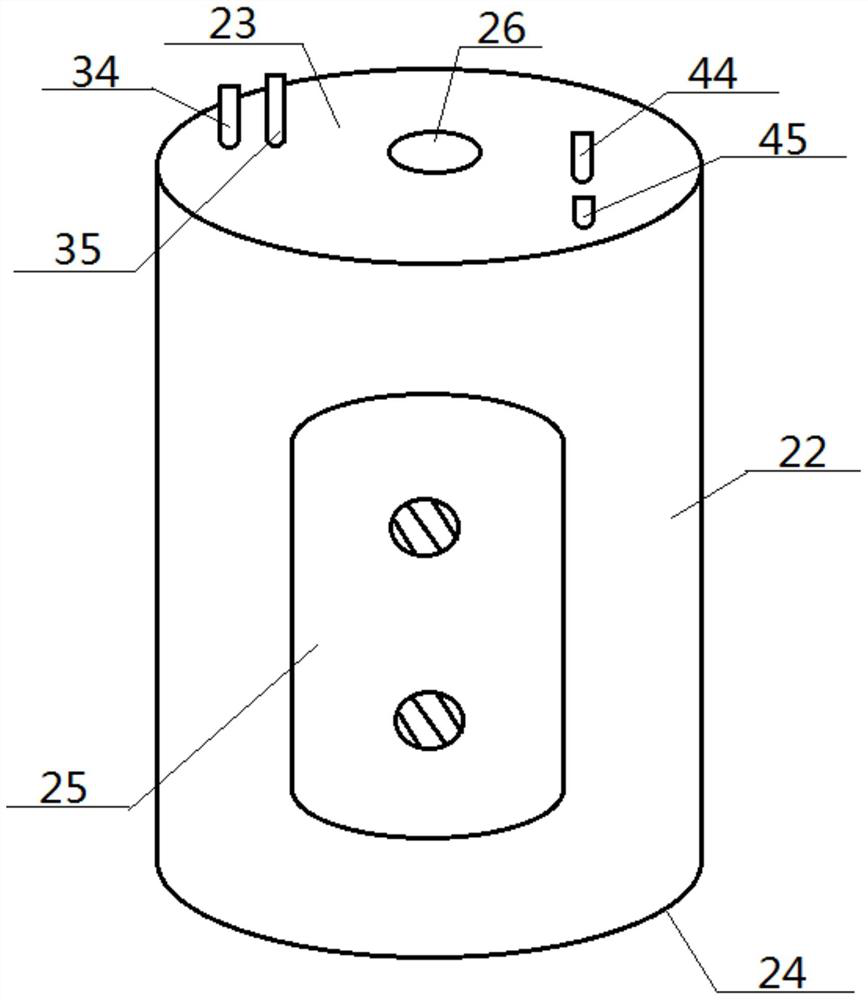

[0056] see figure 1 — Figure 8 , an internal circulating transmission cold stack cylinder, including a liquid-filled cylinder 2 and an inner cylinder cavity 21 provided inside, and the liquid-filled cylinder 2 includes a cylinder side wall 22 and a cylinder top plate 23 and a cylinder bottom plate 24 connected to its two ends , the bottom surface of the cylinder top plate 23 is in contact with the top surface of the cylinder bottom plate 24 through the inner cylinder cavity 21; the first drive roller 3, the second follower roller 5, the third follower roller 51 and the The No. 4 driving roller 4, the No. 1 driving roller 3 and the No. 4 driving roller 4 are respectively located at the two ends of a diagonal line, and the No. 2 follower roller 5 is located on the right side of the No. 1 driving roller 3, so The No. 3 follower roller 51 is located on the left side of the No. 4 drive roller 4; The side circumference of the No. 4 driving roller 4 is driven and matched, and a do...

Embodiment 2

[0059] Basic content is the same as embodiment 1, the difference is:

[0060] A No. 1 fixed roller 31 is arranged on the side of the No. 1 driving roller 3, and the side circumference of the No. 1 fixed roller 31 and the side circumference of the No. 1 driving roller 3 are clamped up and down to carry out transmission cooperation; the No. 4 driving roller The No. 4 fixed roller 41 is arranged on the side of 4, and the side circumference of the No. 4 fixed roller 41 and the side circumference of the No. 4 driving roller 4 are clamped up and down to carry out transmission cooperation; the No. 1 driving roller 3 is located on the No. 1 fixed Between the roller 31 and the No. 3 follower roller 51 , the No. 4 driving roller 4 is located between the No. 4 fixed roller 41 and the No. 2 follower roller 5 .

Embodiment 3

[0062] Basic content is the same as embodiment 1, the difference is:

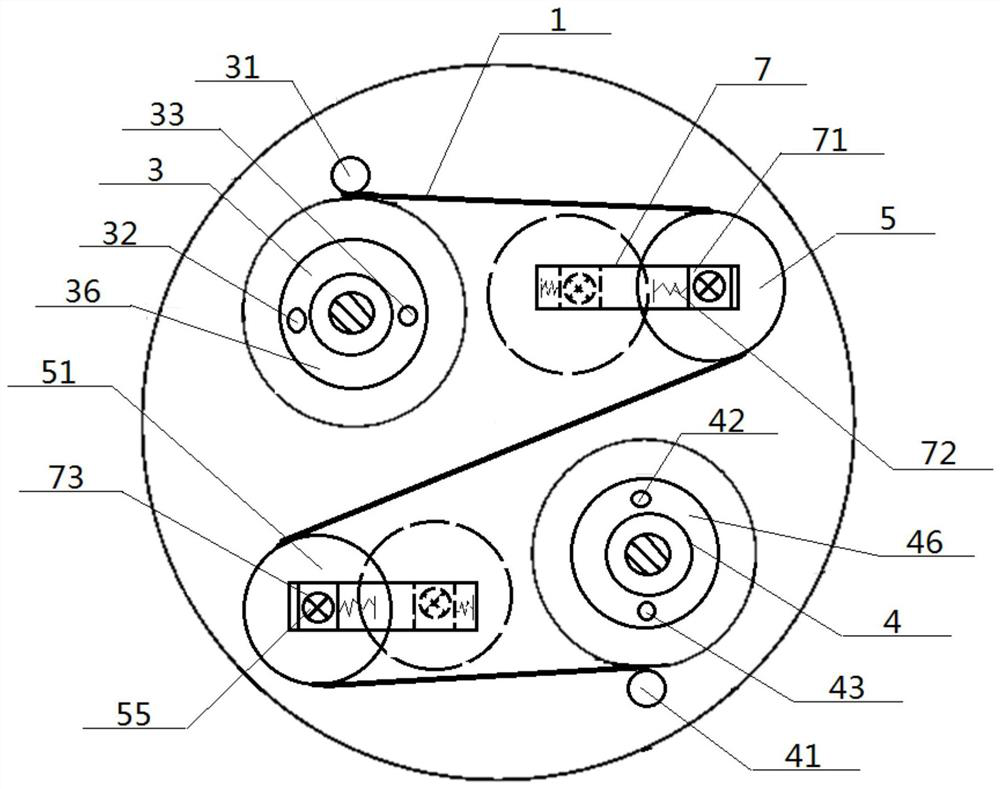

[0063] Structurally: the ends of the No. 2 follower roller 5 and the No. 3 follower roller 51 are set one by one in the roller hole 73, and the roller hole 73 is set in the middle of the roller slider 71. The roller slider 71 is slidingly fitted in the horizontal direction along the inner wall of the roller slider frame 7, the side wall of the roller slider 71 is connected with the inner end of the horizontal spring 72, and the outer end of the horizontal spring 72 faces away from the roller slider 71. Direction extends, and roller slider 71, horizontal spring 72 are all positioned at the inside of roller slider frame 7, and a roller slider 71 corresponds to a roller slider frame 7, and the positions of all roller slider frames 7 are all fixed.

[0064] In terms of method: when the cloth roll 1 drives the No. 2 follower roller 5 and the No. 3 follower roller 51 to rotate together, the side walls of the No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com