Telescopic rotary hydraulic cylinder for realizing rotary action

A technology of telescopic rotation and hydraulic cylinder, applied in the field of hydraulic cylinder, can solve the problems of inconvenient rotation control, lack of control structure to block rotation power, etc., and achieve the effect of high applicability and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

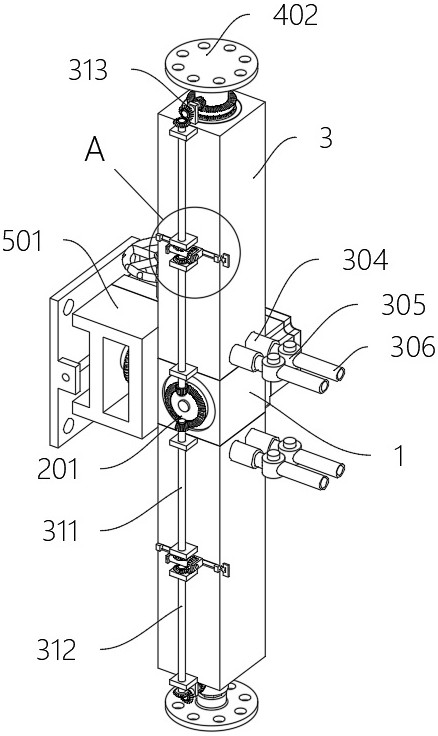

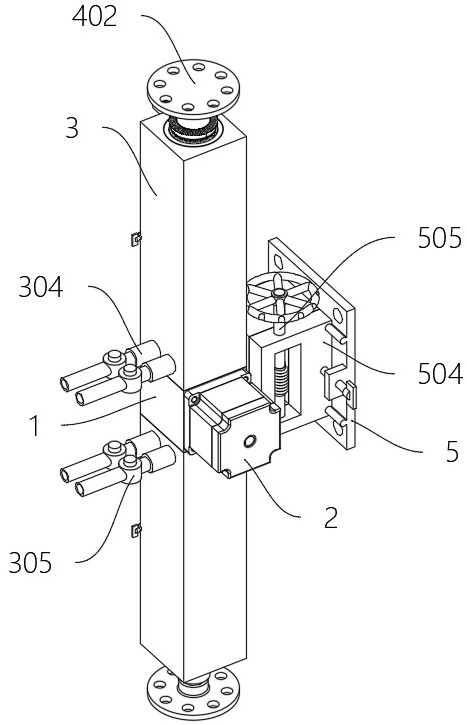

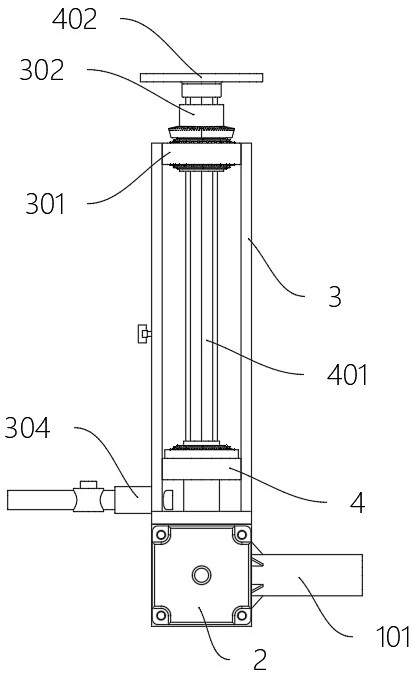

[0031] Example: Please refer to Figure 1 to Figure 8 :

[0032] The present invention proposes a telescopic rotary hydraulic cylinder for realizing rotation, comprising: a central component 1, a through hole is opened in the middle of the central component 1; a servo motor 2, and the servo motor 2 is fixedly arranged on the rear side of the central component 1 After the rotating shaft of the servo motor 2 passes through the front end of the central assembly 1, a bevel gear plate 201 is fixedly arranged; the hydraulic cylinder 3 is fixedly arranged at the upper and lower ends of the central assembly 1; the top middle of the hydraulic cylinder 3 is fixedly provided with a limit The middle of the ring 301 and the limit ring 301 cooperate with the double-row tapered roller bearing to rotate and set the rotating sleeve 302; the piston part 4, the piston part 4 is a T-shaped cylindrical structure, and the piston part 4 is slidingly arranged in the hydraulic cylinder 3; the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com