Online prediction method for chemical components in tobacco leaf curing process based on transfer learning and near infrared spectrum

A technology of near-infrared spectroscopy and transfer learning, which is applied in the field of tobacco leaf curing process analysis, can solve problems such as poor prediction results, long cycle time, and high cost, and achieve the effects of improving prediction accuracy, simple operation, and high robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

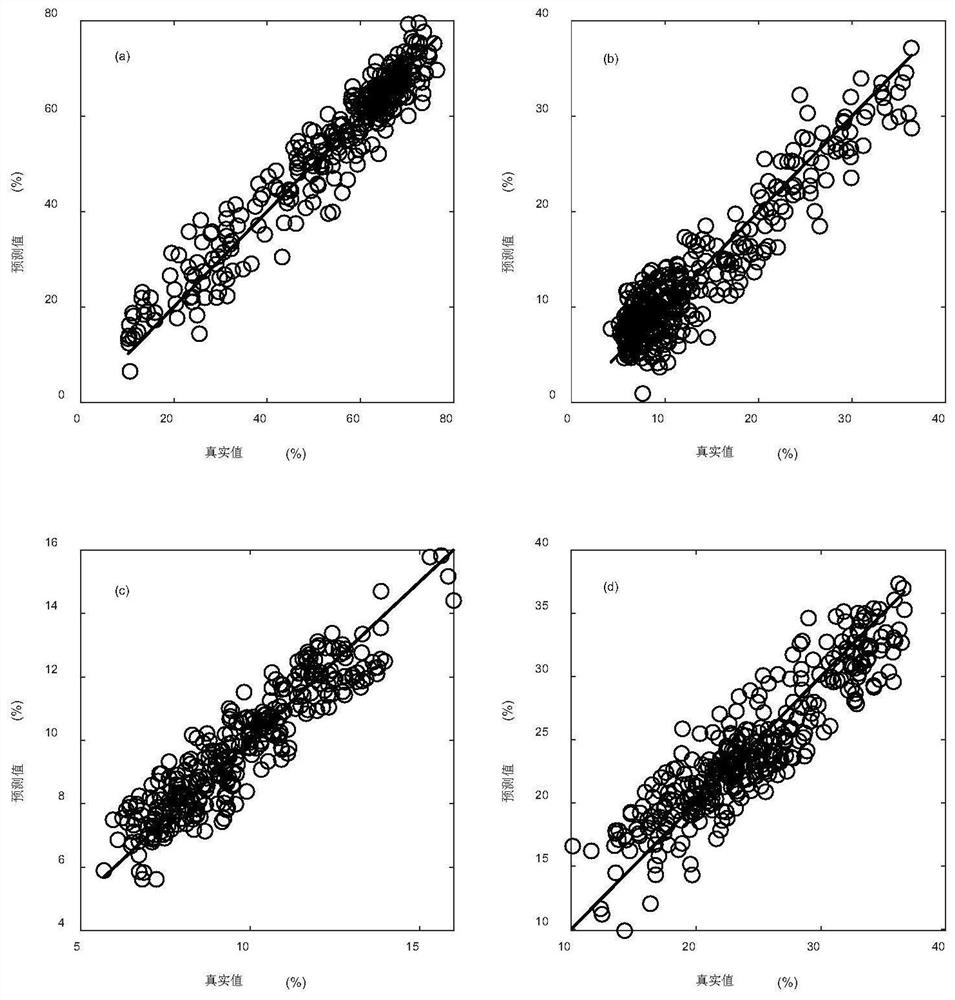

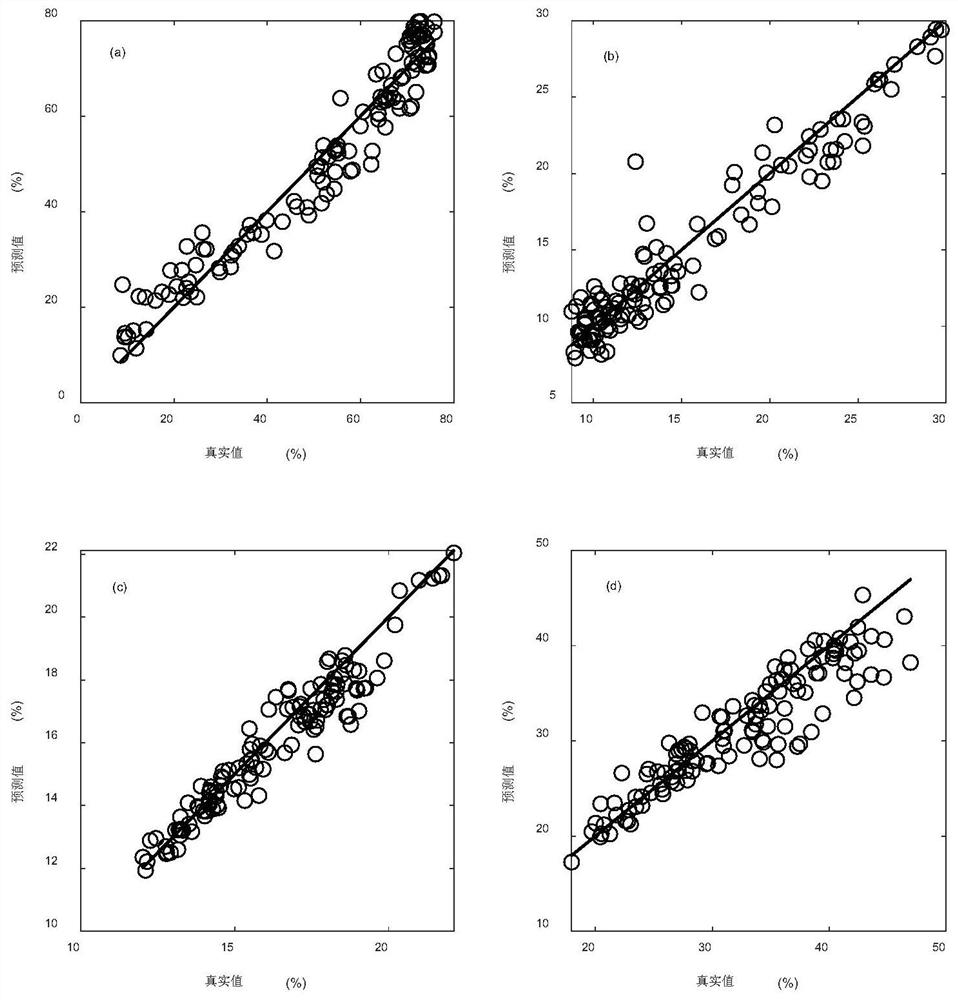

Examples

Embodiment

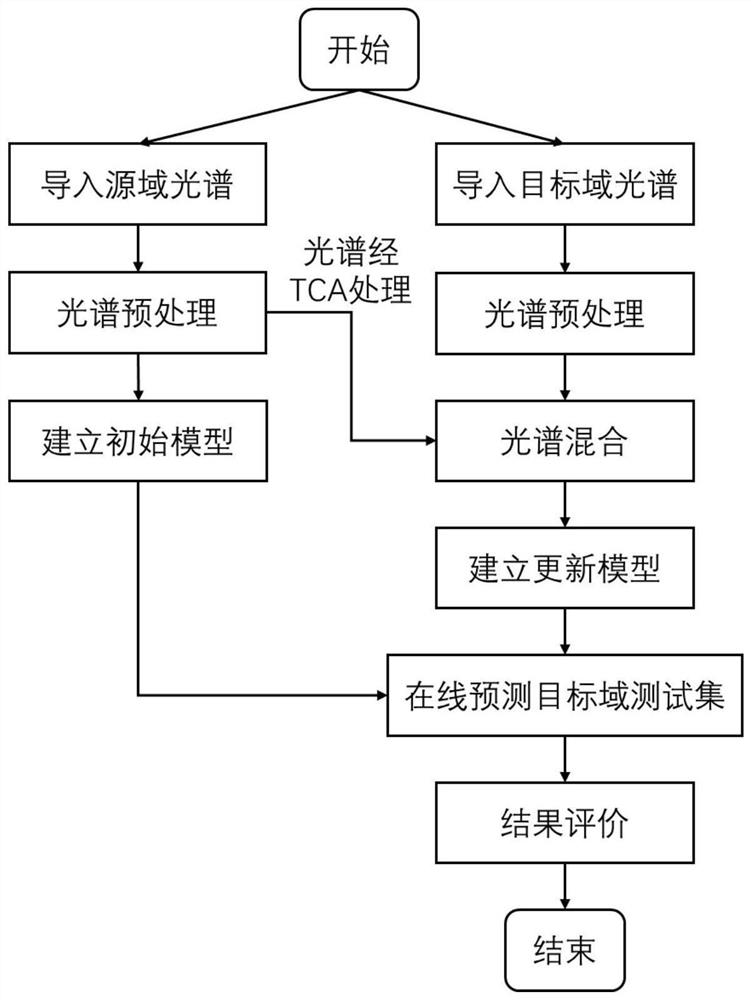

[0045] An online prediction method for chemical components in the tobacco leaf curing process based on migration learning and near-infrared spectroscopy, which specifically includes the following steps:

[0046] (1) Collect tobacco leaf samples at predetermined time intervals during the tobacco leaf curing process, collect the spectra of the tobacco leaf samples and determine the chemical composition values, specifically including:

[0047] When collecting the spectrum of tobacco leaves, for each of the tobacco leaf samples, use a fiber optic probe-type near-infrared spectrometer to avoid leaf veins during collection, and measure the spectrum with the fiber optic probe vertically close to the tobacco leaf surface to obtain a stable, smooth and accurate spectrum Information, without destroying the tobacco leaves, convenient and fast;

[0048] Use one of the methods of spectrophotometry, gas chromatography-mass spectrometry, liquid chromatography, continuous flow method, and sol...

specific Embodiment

[0071] An online prediction method for chemical components in the tobacco leaf curing process based on migration learning and near-infrared spectroscopy, which specifically includes the following steps:

[0072] (1) The flue-cured tobacco variety Yunyan 87 was selected, and the pre-cured tobacco leaves were preliminarily screened, and the upper complete and pest-free tobacco leaves with relatively consistent size, shape and maturity were selected for the curing test.

[0073] (2) Collecting samples and measuring near-infrared spectra: Sampling was performed at intervals of 8 hours during the curing process, and 50 tobacco leaf samples were taken each time. Using a fiber optic probe-type near-infrared spectrometer, the fiber optic probe was vertically attached to the tobacco leaf surface to measure the spectrum. The spectral range was set to 900nm-1700nm, the integration time was set to 10ms, and the number of scans was set to 32 times.

[0074] (3) Determination of the water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com