Resistor layout arrangement structure applied to high-precision and high-common-mode differential amplifier and trimming method

A differential amplifier, high-precision technology, used in special data processing applications, instruments, electrical digital data processing, etc. The effect of solving the poor initial matching degree, reducing the deviation and reducing the cost of trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

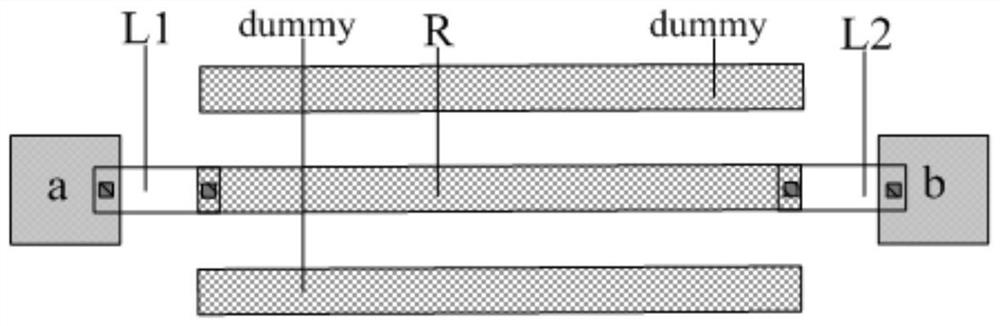

[0043] See Figures 1 to 7 A resistance layout arrangement applied to high-precision high-interstitial difference amplifiers, including two resistance arrays different from resistance. Among them, the resistance array having a small resistance is the first resistance array, and the resistive array having a large resistance is listed as a second resistance array.

[0044] The first resistor array and a second resistor array are connected by a metal wire.

[0045] The second resistor array includes a series (N-1) strip rectangular resistance and a repairable backpack resistor R. N . (N-1) strip rectangular resistance is recorded as R 1 R 2 , ..., r N-1 . N is a resistance ratio of the second resistance array and the first resistance array.

[0046] The first resistor array is a rectangular resistance, and the resistance value is reserved as R.

[0047] The resistance of the second resistor array is N * R.

[0048] (N-1) Stand-shaped rectangular resistance is placed in parallel.

[00...

Embodiment 2

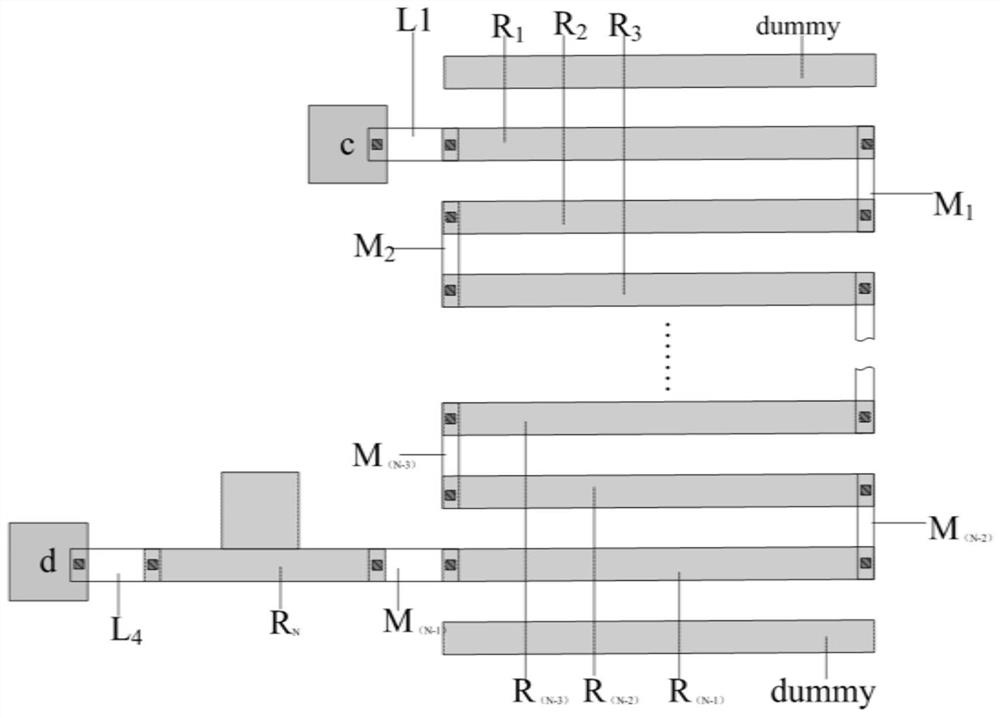

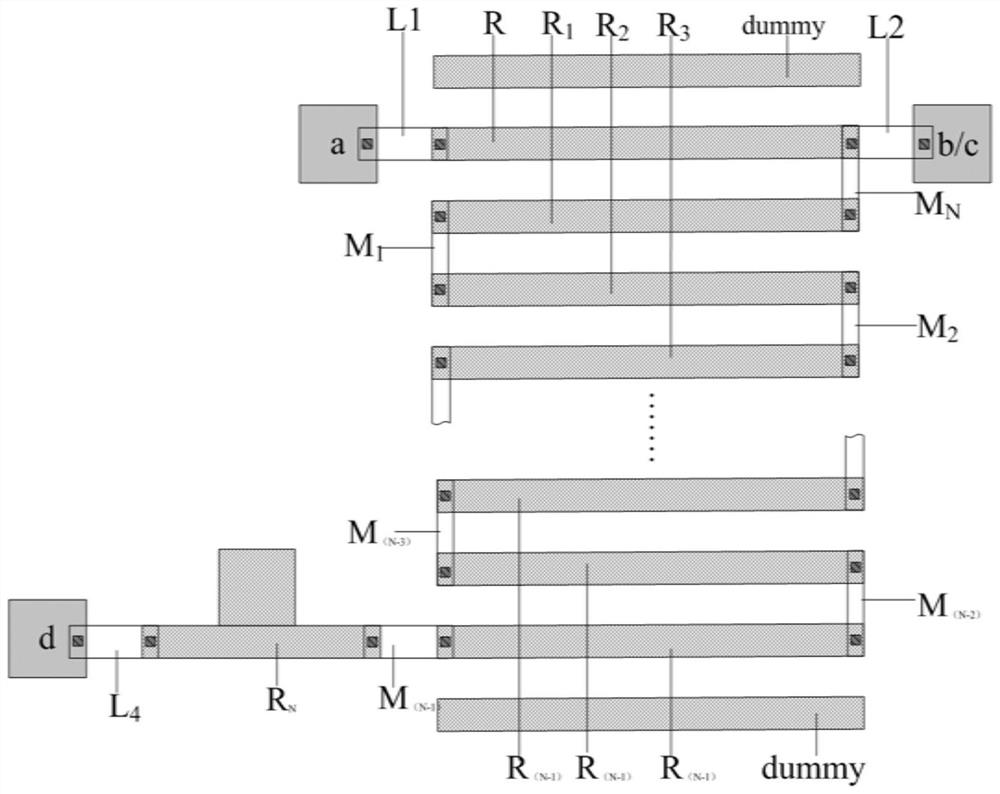

[0059] A resistance layout arrangement applied to high-precision high-interstitial difference amplifiers, including two resistance arrays of different resistance. Among them, the resistance array having a small resistance is the first resistance array, and the resistive array having a large resistance is listed as a second resistance array.

[0060] The first resistor array and a second resistor array are connected by a metal wire.

[0061] The second resistor array includes a series (N-1) strip rectangular resistance and a repairable backpack resistor R. N . (N-1) strip rectangular resistance is recorded as R 1 R 2 , ..., r N-1 . N is a resistance ratio of the second resistance array and the first resistance array.

Embodiment 3

[0063] A resistance layout arrangement applied to a high-precision high-interstitial difference amplifier, the main structure is shown in Example 2, wherein the first resistor array is a rectangular resistance and a resistance value is R.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com