Method for monitoring assembly process of prefabricated concrete member based on stereoscopic vision

A prefabricated concrete, stereo vision technology, applied in image data processing, complex mathematical operations, instruments, etc., can solve the problems of high cost of TLS equipment, inability to use in large quantities, estimated depth errors, etc., to reduce labor costs and equipment costs, Reduce labor and equipment costs, and detect fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

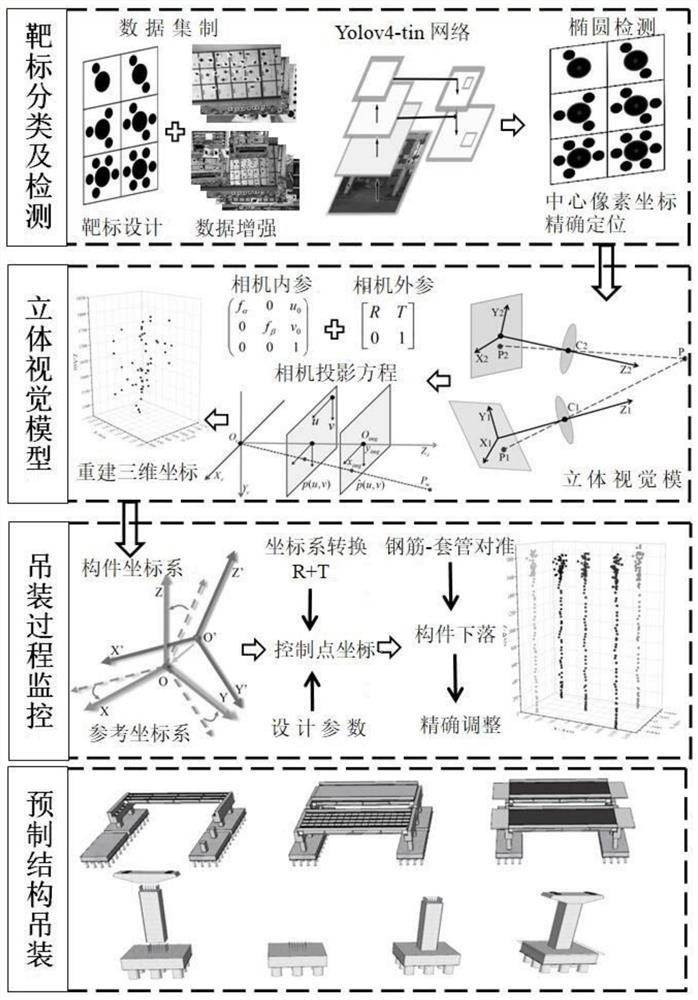

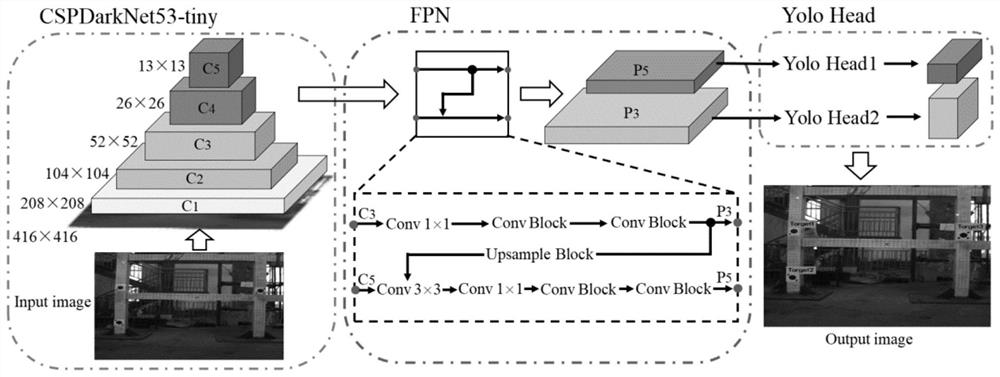

[0053] Such as figure 1 As shown, it is a frame diagram of the method for monitoring the assembly process of precast concrete components based on stereo vision in the present invention. The method includes three-dimensional displacement measurement with binocular stereo vision, ellipse detection based on deep learning, and structural hoisting monitoring based on coordinate system conversion. According to the returned coordinate information, the deviation can be clearly obtained, and the coordinates of the control points can be adjusted to the ideal elevation. Finally, the hydraulic machine is used to precisely adjust the plane coordinates of the control points. After se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com