Novel integrated high-voltage circuit on-off connection system

A high-voltage circuit and connection system technology, applied in the direction of circuits, connections, and components of connecting devices, etc., can solve the problems of relay adhesion failure, increased component size, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

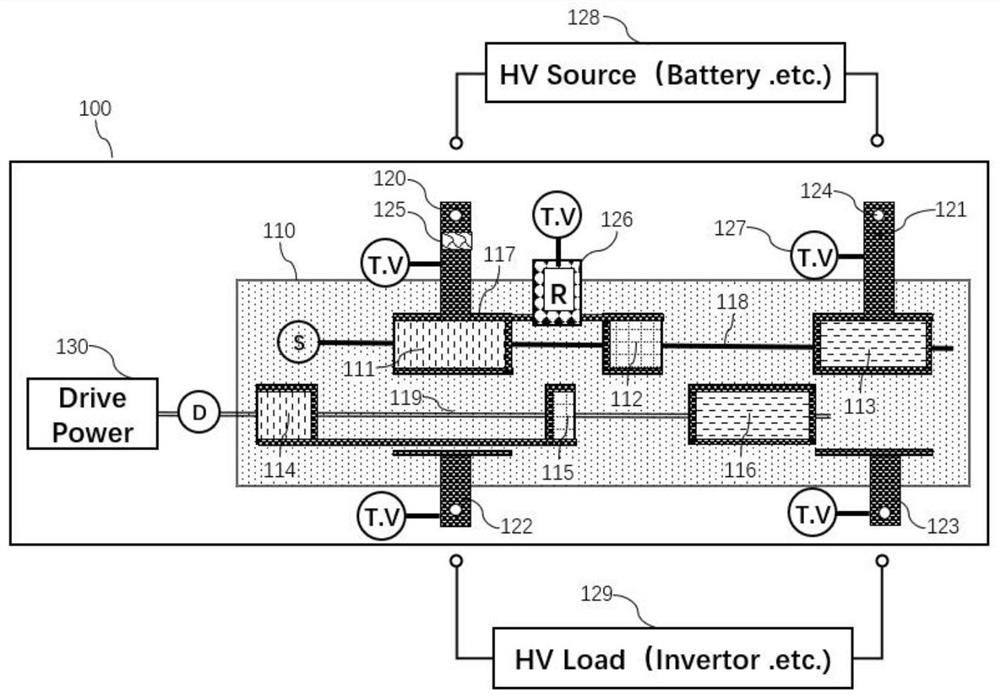

[0048] A new type of integrated high-voltage circuit on-off connection system, such as figure 1 , Figure 3-Figure 13 As shown, it includes a first high-voltage power supply 128, a high-voltage load 129 and a high-voltage on-off connection device 100. The disconnecting device 100 is electrically connected, the high-voltage load 129 is electrically connected to the high-voltage connecting device 100 through the third high-voltage connecting terminal 122 and the fourth high-voltage connecting terminal 123 of the high-voltage connecting device 100, and the first high-voltage power supply 128 is connected to the high-voltage The load 129 is connected through the connection interface 121 of the high-voltage on-off connection device 100 to form a high-voltage circuit, and the high-voltage on-off connection device 100 is fixedly connected through the structure 110;

[0049] The high-voltage on-off connection device 100 includes a first assembly shaft 118, a first contact body 111, a...

Embodiment 2

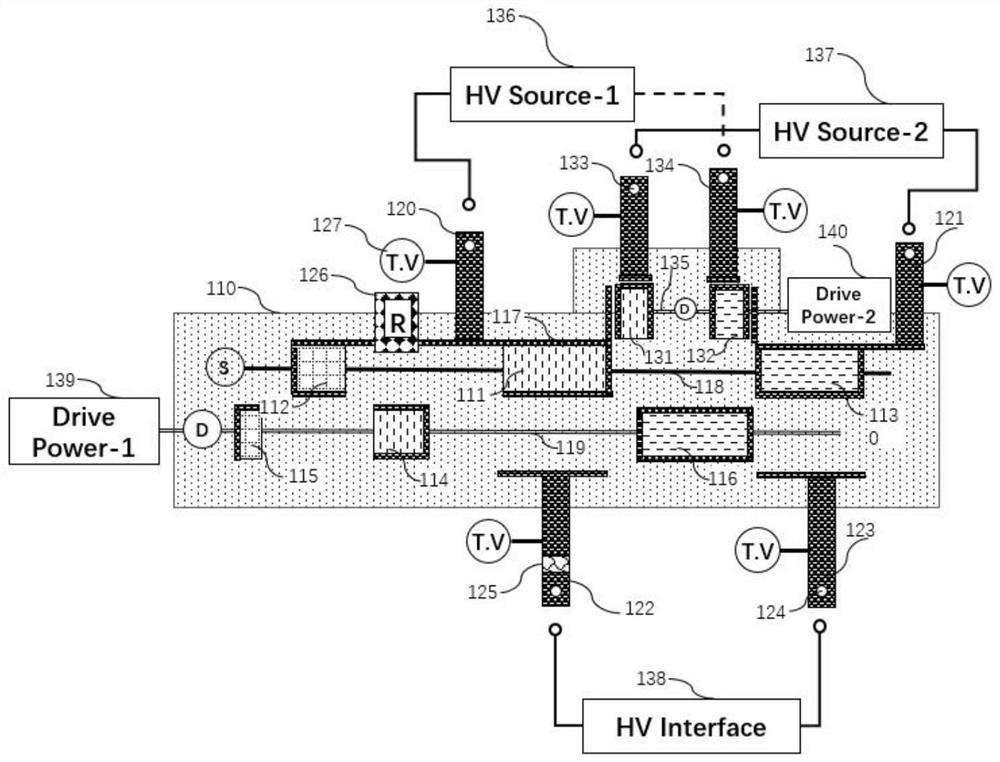

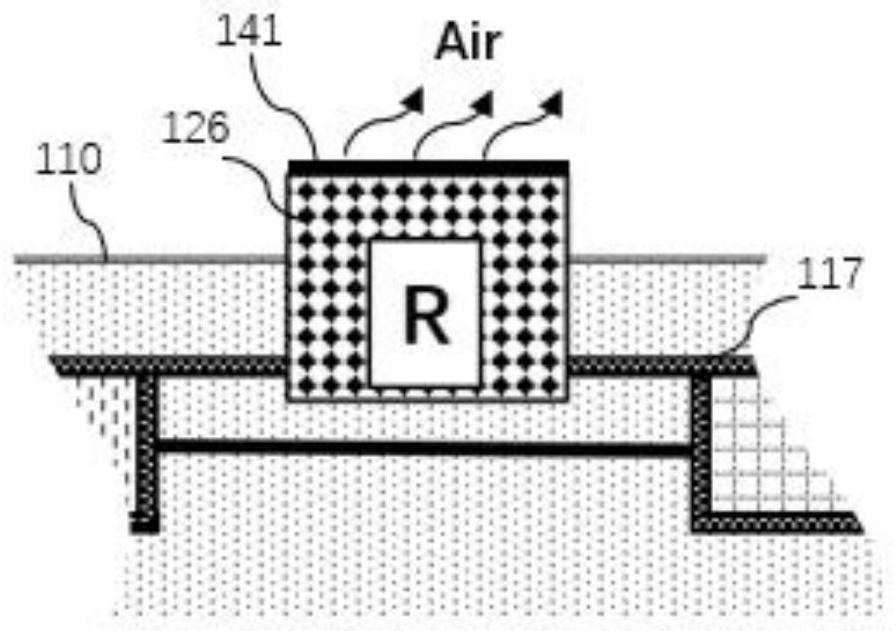

[0069] Such as figure 2 , Figure 14 with Figure 15 As shown, in scenarios where multiple high-voltage power supplies require different combinations, the high-voltage on-off connection device 100 can be expanded. Taking two high-voltage power supplies as an example, as Figure 14 As shown, one pole of the second high-voltage power supply 136 is connected to the first high-voltage connection terminal 120, and the other pole is connected to the fifth high-voltage connection terminal 134 to realize equipotential with the second high-voltage connection terminal 124; one pole of the third high-voltage power supply 137 One pole is connected to the second high-voltage connection terminal 124, and the other pole is connected to the sixth high-voltage connection terminal 133 to achieve equipotentiality with the first high-voltage connection terminal 120; the third assembly axis 135 is a heat sink structure; generally, the second high-voltage connection is realized. The parallel rel...

Embodiment 3

[0073] Such as Figure 16 As shown, the high-voltage on-off connection device 100 can be integrated and expanded with similar push-in connectors to Figure 16 For example, for a high-voltage on-off connection device 150 with a quick-plug connection function, the seventh high-voltage connection terminal 151 and the eighth high-voltage connection terminal 152 can be connected to the fourth high-voltage power supply 168, and the ninth high-voltage connection terminal 158 can be connected to the tenth high-voltage connection. The terminal 159 can realize a quick-plug connection with the outside of the high-voltage on-off connection device 150 with a quick-plug connection function, such as the eleventh high-voltage connection terminal 164 and the twelfth high-voltage connection terminal 165 on the external component 166;

[0074] The electrical components inside the high-voltage on-off connection device 150 with the function of quick-plug connection, such as the resistor 156, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com