Motion shaft positioner for artificial knee joint replacement

An artificial knee joint and motion axis technology, applied in the direction of knee joints, joint implants, joint implants, etc., can solve the problems of too much resection of the tibial lateral condyle, insufficient resection, inconvenient modification of the knee joint surface, etc., and achieve saving The effect of time and money, simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to facilitate the explanation of the present invention, the present invention is intended to be expressed in a specific embodiment. Various different objects are depicted in a ratio, size, deformation amount, or displacement amount suitable for explanation, rather than drawing according to the proportion of the actual components, and will be described.

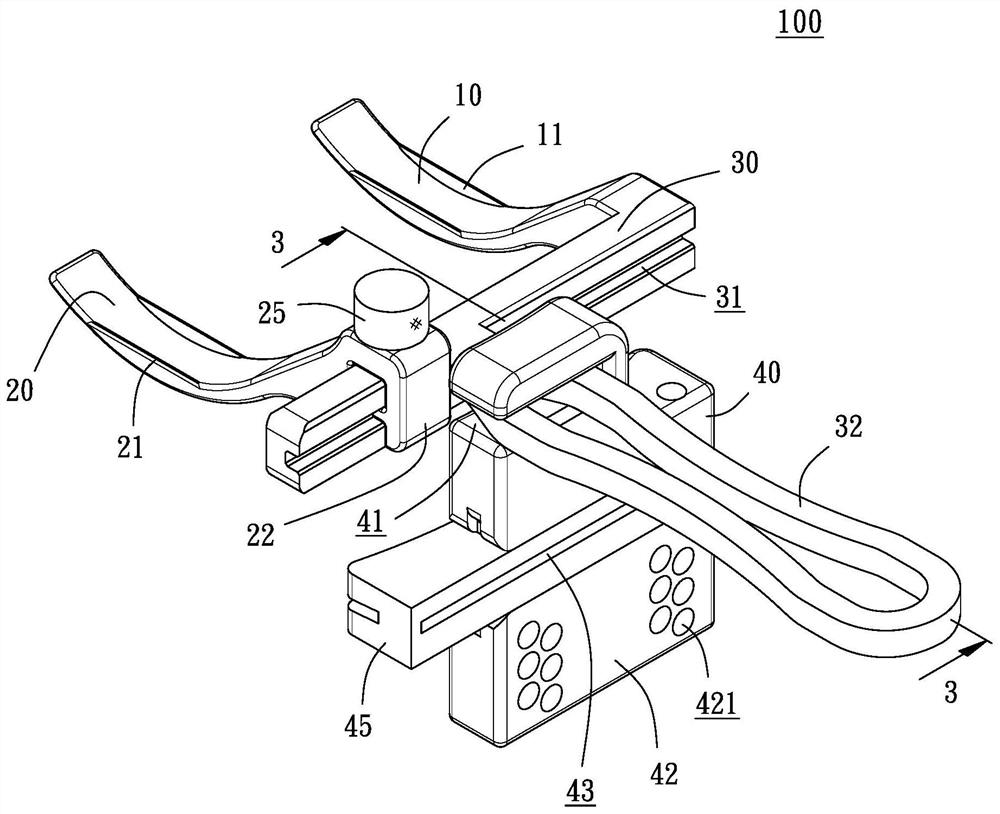

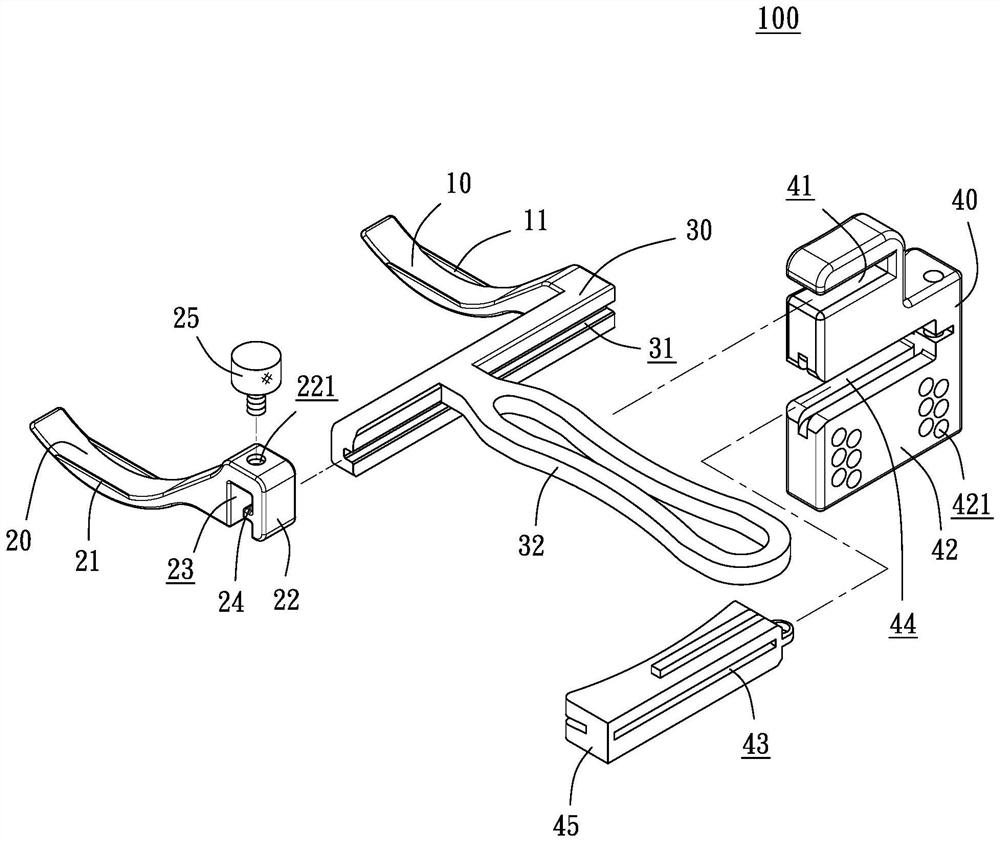

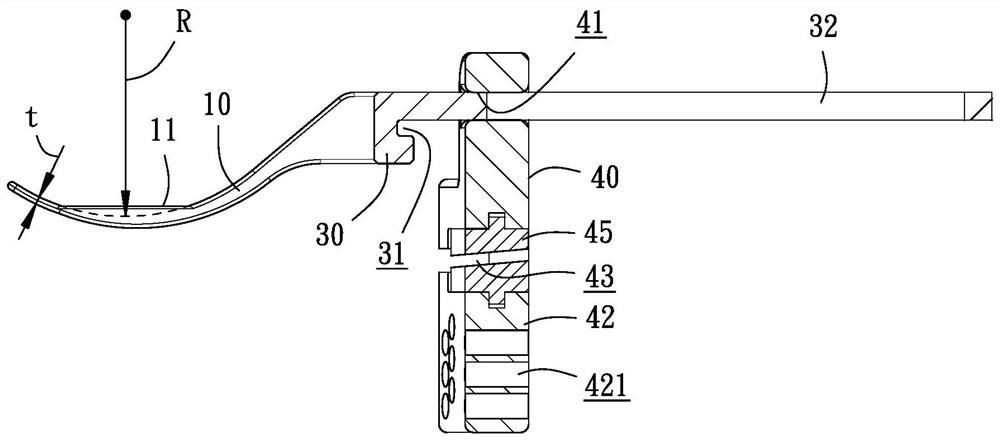

[0046] See Figure 1 to 8 As shown, the present invention provides a motion shaft positioner 100 for artificial knee joint replacement, as the name sustain is used in artificial knee joint replacement, and the definition of this motion axis is clearly described in the background art. Further details will be described again. The motion shaft positioner 100 mainly includes a spoon arm 10, 20 and a joint body, and further includes a guiding cutting member 40 in a preferred embodiment, wherein:

[0047] The spoon arm 10, 20, and the shape are distinguished, respectively, and the curved arc shape described in the scoop i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com