Dispersion machine

A technology of dispersing machine and body, applied in mixers, mixer accessories, shaking/oscillating/vibrating mixers, etc., can solve the problem that the dispersing blade does not move up and down, and does not have automatic cleaning, etc., to improve the vibration effect and reduce foam. , the effect of increasing the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

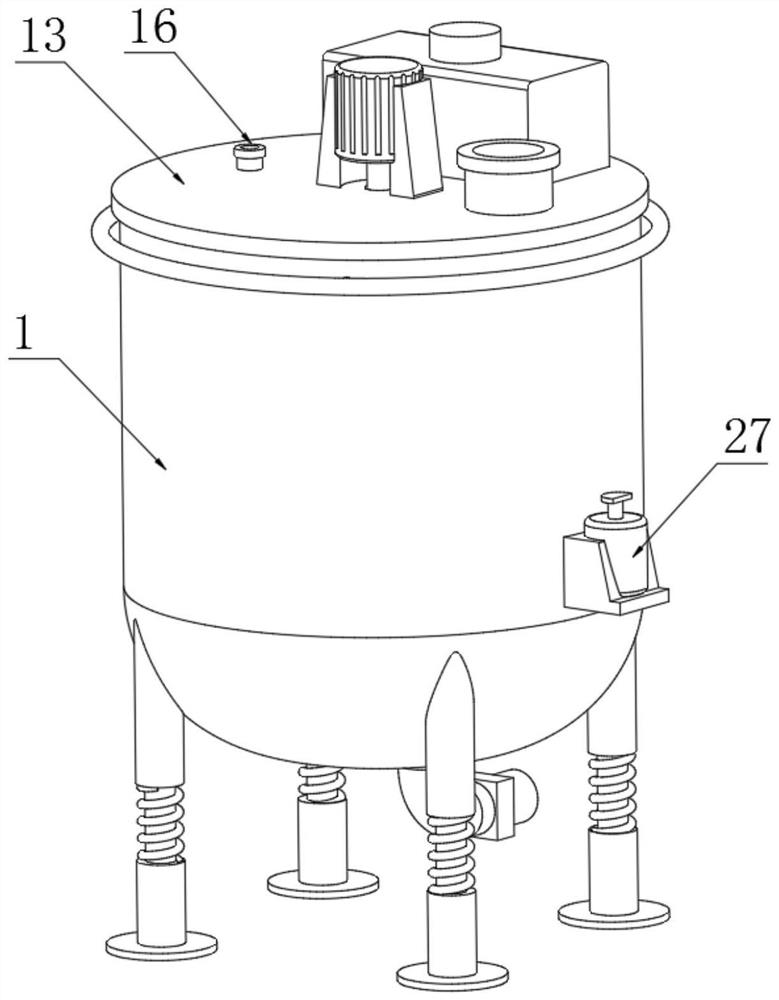

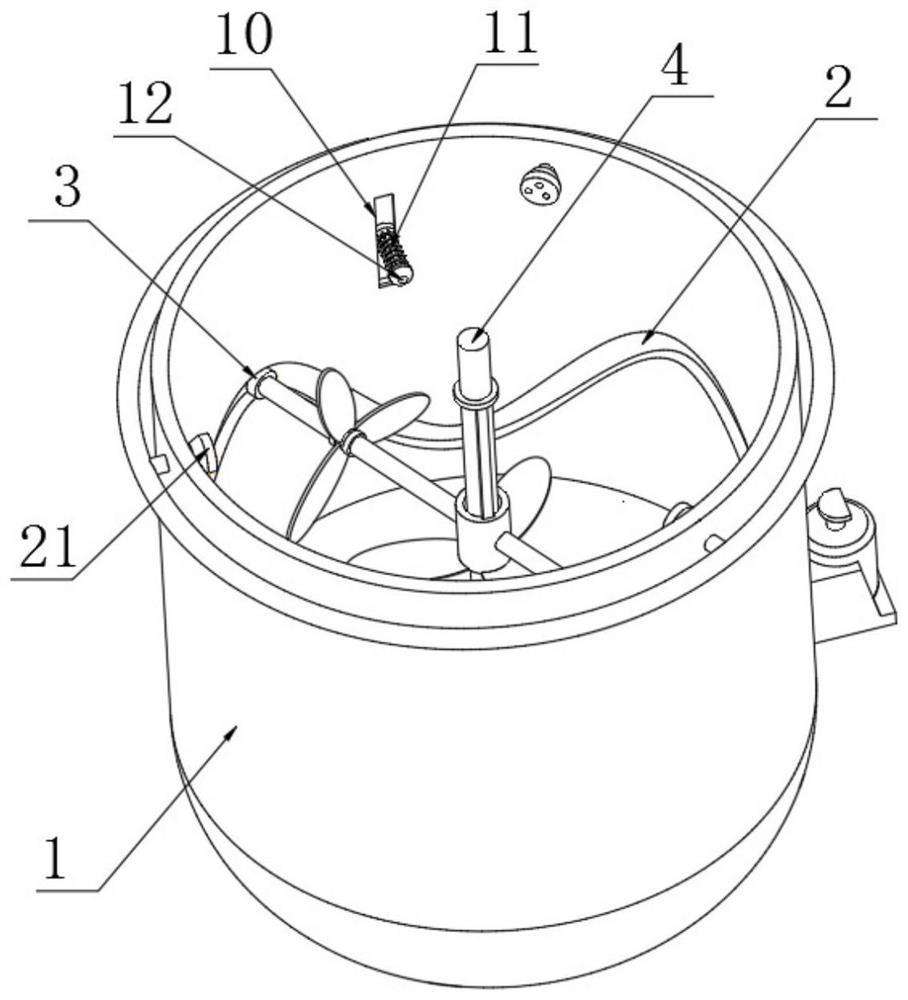

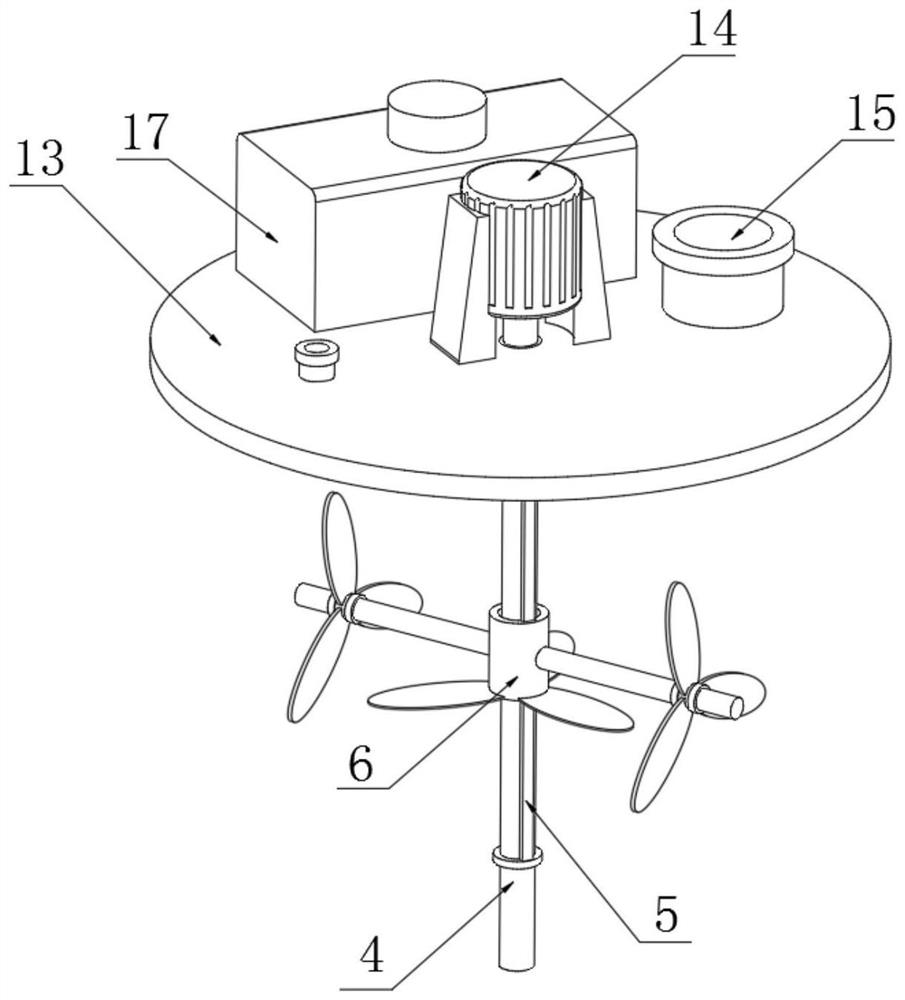

[0029] see Figure 1-7 , the present invention provides the following technical solutions: a dispersing machine, including a body 1, the inner wall of the body 1 is provided with a wave groove 2, the inside of the wave groove 2 is slidingly connected with a slider 3, and the inner bottom wall of the body 1 moves through a coupling Connected with a transmission rod 4, one side of the outer surface of the transmission rod 4 is fixedly connected with the limit block 5, the outer surface of the transmission rod 4 is sleeved with a movable cylinder 6, one side of the outer surface of the movable cylinder 6 is fixedly connected with a support rod 7, and the movable The lower surface of the cylinder 6 is fixedly connected with the first dispersing blade 8 , the middle part of the outer surface of the support rod 7 is rotatably connected with the second dispersing blade 9 , and the support rod 7 is movably connected with the slider 3 .

[0030] In a specific embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com