Efficient and rapid grain screening device

A screening device and fast technology, applied in the direction of screening, removing smoke and dust, and grilling, can solve the problems of cumbersome operation process, waste of time, and low screening efficiency, and achieve simple operation process, increase flexibility, and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

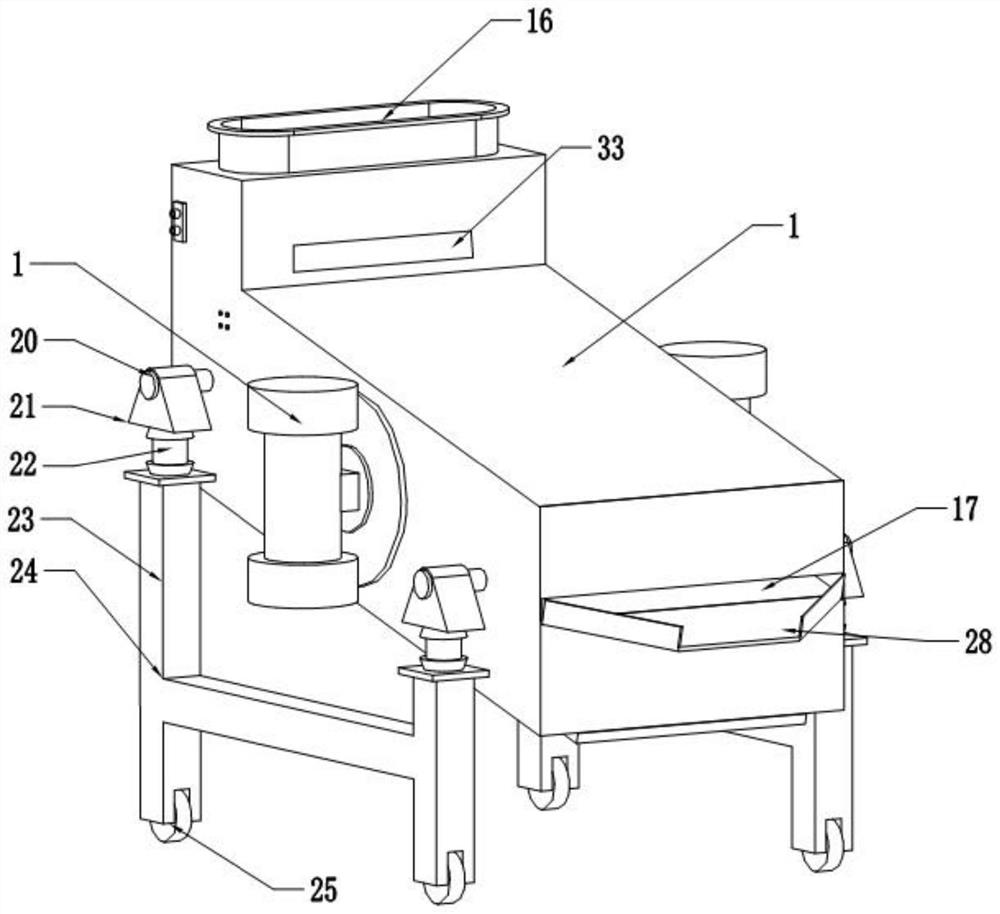

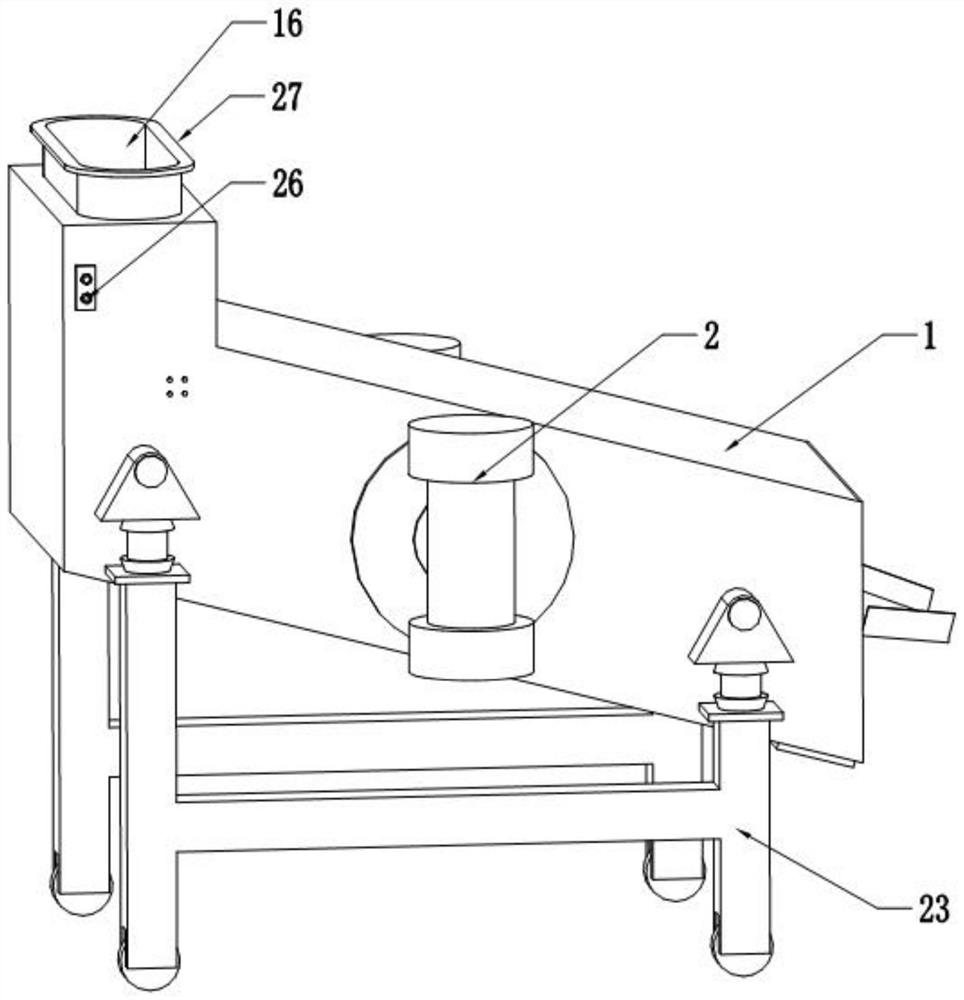

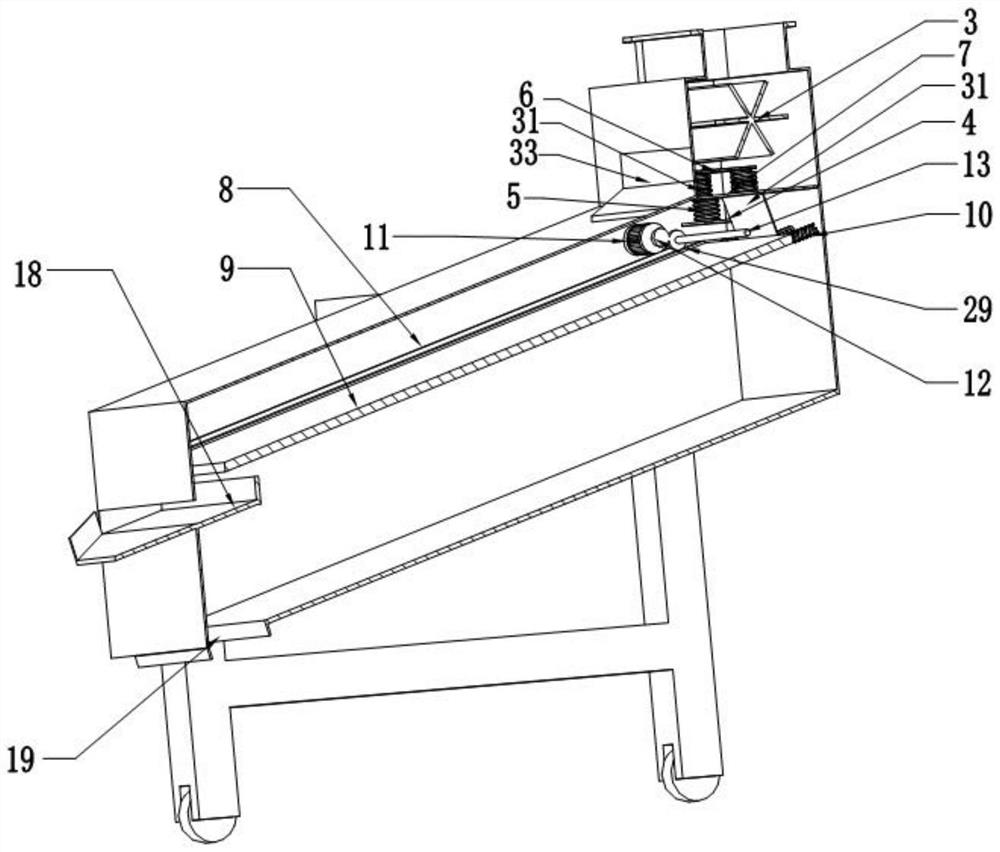

[0030] See figure 1 , 5The present invention provides a technical solution: a highly efficient fast food screening device, including the box 1, the casing 1 side is provided with a vibration motor 2, and a feeding port 16 is provided at the top of the casing 1, and the feed port 16 is provided. The round bulk plate 27, the casing 1 is rotated and connected to the hexagle shunting plate 3, the width of the hexafa shunt plate 3 is larger than the width of the feed port 16, and the inner wall of the casing 1 is provided with a plurality of sets of fixing plates 4, and the fixed plate 4 is provided. There is a buffered spring 5, and the end of the buffer spring 5 is respectively provided with the first buffer plate 6 and the second buffer plate 7, and the center position of the hexafa shunt plate 3 is located at one end away from the first buffer 6, which can make it from entering The mixture poured by the inlet 16 can be driven on the hexafan shunting plate 3 and drive the hexafan sh...

no. 2 example

[0036] Based on the first embodiment, a highly efficient fast food screening apparatus is provided, and a large impurity such as stone or the like present in the food inside is not easily screened during actual use of the apparatus. When the vibration motor 2 drives the device to move downward, since the buffer spring 5 is buffered, only the first buffer plate 6 and the second buffer plate 7 are slow, the first buffer board 6 and the first buffer plate 6 and the first buffer board 6 The two buffer plate 7 cannot be separated from the top mixed grain, so the effect of collision extrusion cannot be achieved well, and the mixed food is only in the top of the first buffer plate 6 and the second buffer plate. The extrusion sliding out of the row is poor, and even impacts its elastic shake, so that the large bonded block food is unable to squeeze, affecting the subsequent screening, in order to solve this problem, the device can be large The bonding block performs effective crushing, im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com