Robot motion information planning method and related device

A technology of robot motion and motion information, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of not considering time, energy consumption, and the inability to meet the high efficiency and low energy consumption of industrial robots, and achieve the effect of improving the optimization accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

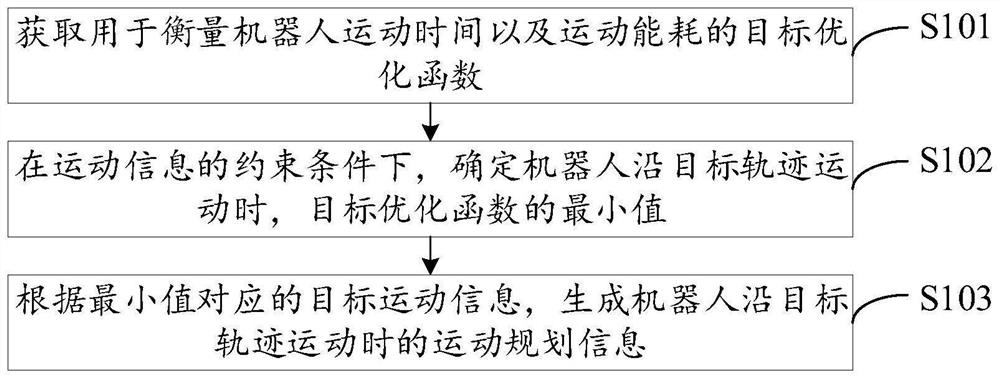

[0048] S103-1. Acquire target motion information corresponding to the minimum value.

[0049] S103-2, performing interpolation processing on the target motion information through a quintic polynomial to obtain motion planning information when the robot moves along the target trajectory.

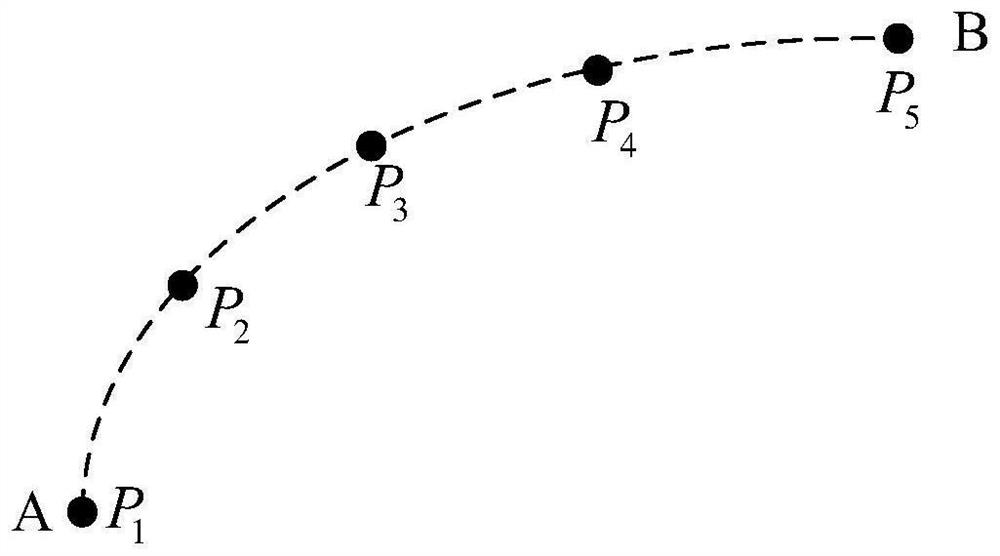

[0050] Exemplary, continue to see image 3 Multiple sampling points in , denoted as P 1 ,P 2 ,P 3 ,P 4 ,P 5 ; For the convenience of description, select P 2 and P 3 Be explained. When the objective optimization function is minimized, it can be solved that the end of the industrial robot is located at P 2 When , the respective angles, rotational speeds and moments of the six joints; and the end at P 3 , the respective angles, rotational speeds and moments of the six joints. Therefore, when the end of the industrial robot moves from P 2 Movement to P 3 During this period, it is necessary to fit the respective angles, rotational speeds and torques of the six joints by means of interp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com