Mold for preparing composite material curved surface honeycomb structural member and preparation method of structural member

A composite material and honeycomb structure technology, which is applied in the field of preparation of composite curved honeycomb structures, can solve problems such as the inability to prepare an integrated composite curved honeycomb structure, and achieves the effects of high stiffness, uniform pressure, and prevention of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1, a method for preparing a honeycomb cylinder of carbon fiber reinforced epoxy resin-based composite material T300:

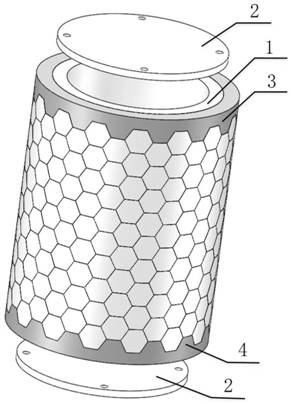

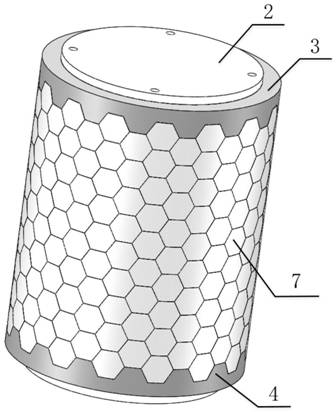

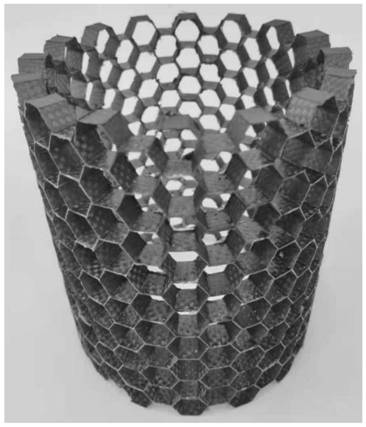

[0068] like Figure 4 As shown, a mold for preparing a composite material honeycomb cylinder includes a curved bottom mold, a curved honeycomb frame mold, a plurality of honeycomb modules and a base;

[0069] like Figure 5 and Image 6 As shown, the curved surface bottom mold is a steel circular cylinder mold 1. In order to prevent the external pressure from acting on the outside of the vacuum bag when the composite material honeycomb cylinder is formed in the autoclave, because the middle of the circular cylinder mold is hollow, It will force the vacuum bag to move to the hollow part of the circular cylinder mold. If it moves to a certain extent, the vacuum bag will be torn, which will eventually affect the molding quality of the test piece. The two ends of the circular cylinder mold 1 are also equipped with circular cover plates 2 respectiv...

Embodiment 2

[0089] Example 2, a method for preparing a curved honeycomb panel of carbon fiber reinforced epoxy resin-based composite material T300:

[0090] like Figure 11 , Figure 12 As shown, a mold for preparing a composite material curved honeycomb panel includes a curved bottom mold, a curved honeycomb frame mold, a plurality of honeycomb modules and a base;

[0091] Described curved surface base mold is the curved plate 10 made of steel, and the curvature of each point of curved plate 10 is identical;

[0092] The curved honeycomb frame mold is a closed silicone rubber ring mold, and the ring mold includes a frame lower mold 11, a frame upper mold 12, a frame left mold 13 and a frame right mold 14, and the frame lower mold 11 1. The frame left side mold 13, the frame upper mold 12 and the frame right side mold 14 are sequentially connected end to end to form an annular mold, and the curvature of the inner surface of the annular mold is the same as that of the outer surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com