MPU chip or MCU chip

A chip and printing material technology, applied in printing and other directions, can solve the problems of reduced service life, printer damage, and printer's inability to accurately predict the remaining ink volume, to achieve the effect of protecting the printer, avoiding damage or reducing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The terms used in the embodiments of the present application are only used to explain specific embodiments of the present application, and are not intended to limit the present application.

[0040] In the related art, a solution for detecting the residual liquid level in the ink cartridge of the printer is as follows:

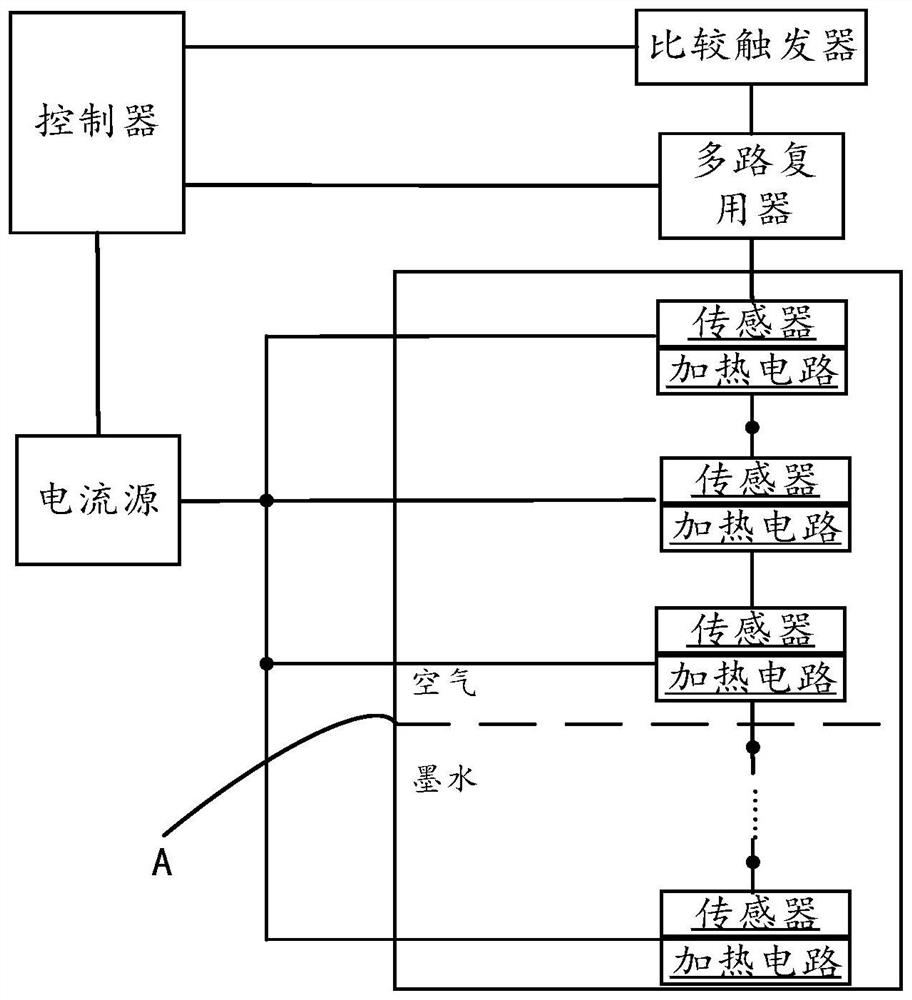

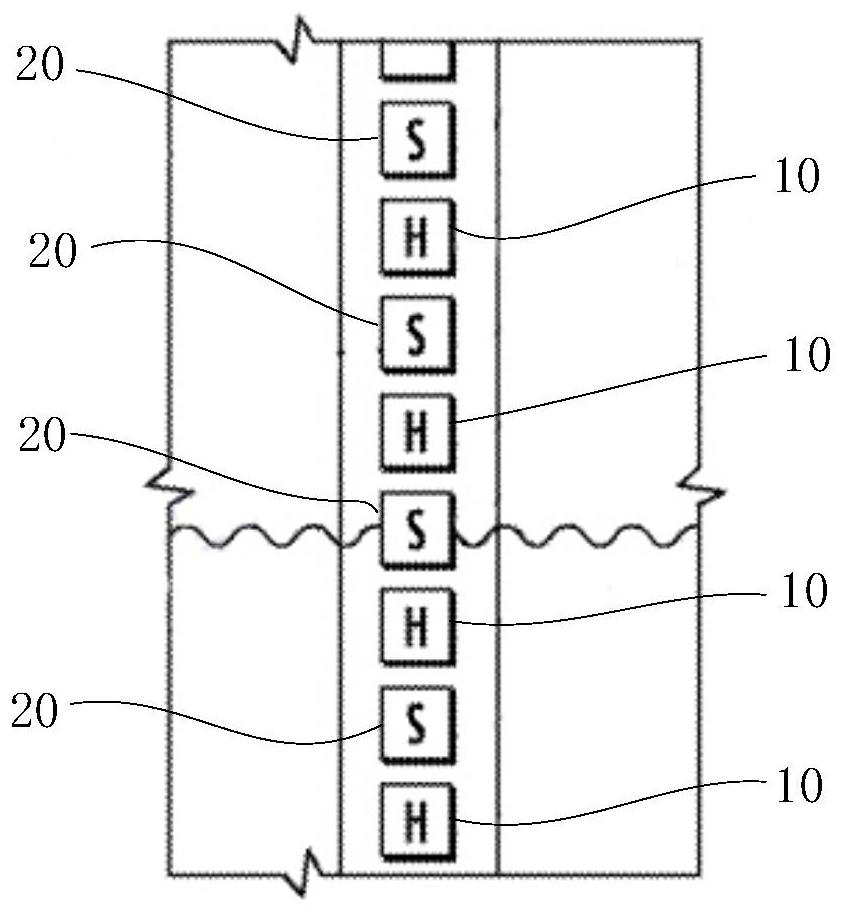

[0041] refer to figure 1 as shown, figure 1 It is a structural schematic diagram of the residual liquid level detection circuit, and the circuit may include:

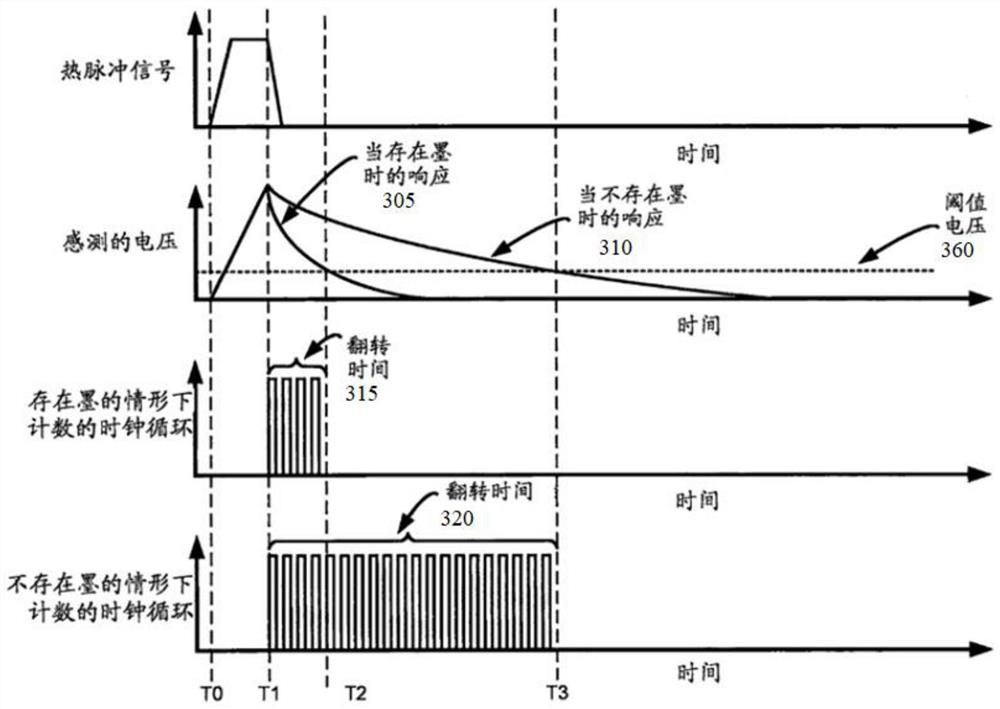

[0042] The control circuit (controller) controls the current source to supply power to the sensor and controls the operation of the heating circuit; the heating circuit is arranged in the ink cartridge to generate heat and change the temperature; the sensor is arranged in the ink cartridge to sense the nearby position The temperature change at the sensing position or substantially in the vicinity of the sensing position (for example, within 10 microns) is converted into a voltage, that is, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com