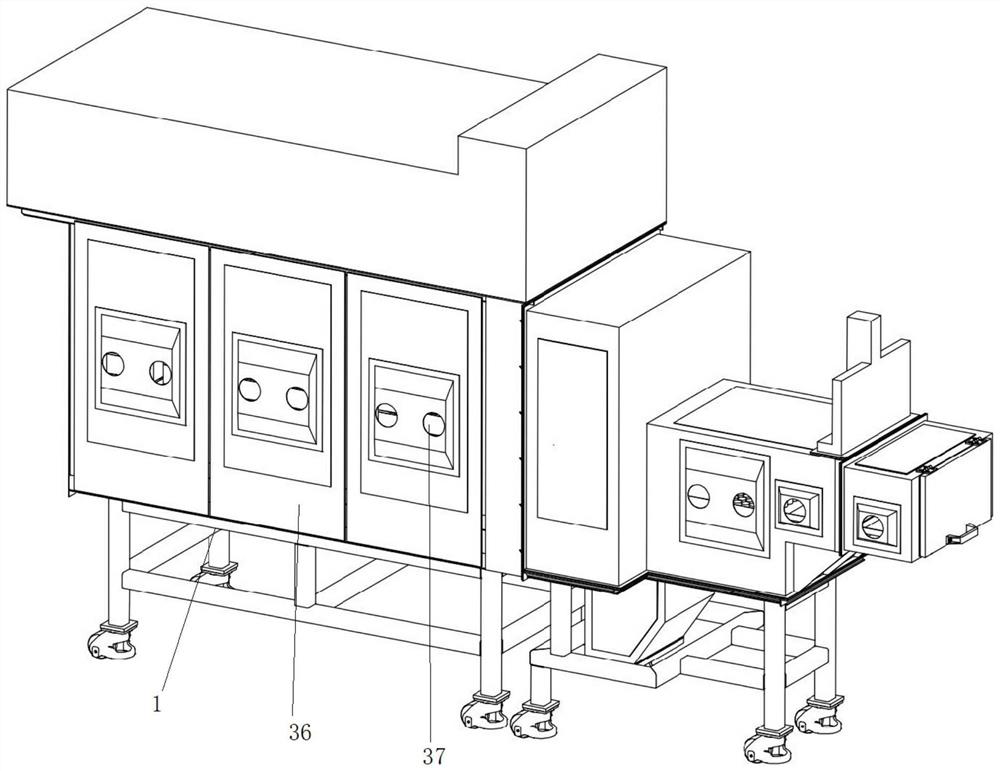

Automatic stacker crane for technological process in rare earth permanent magnet industry

A technological process, rare earth permanent magnet technology, applied in the direction of automatic packaging control, stacking of objects, de-stacking of objects, etc., can solve the problems of troublesome operation and low efficiency, and achieve the effect of fully automatic process and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

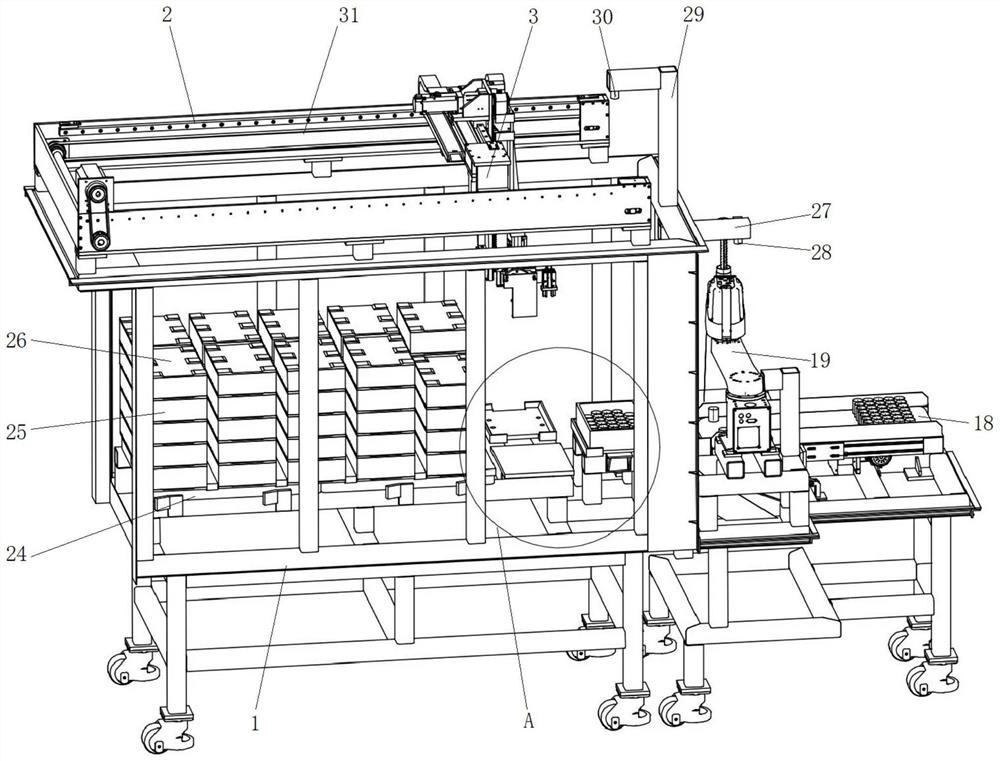

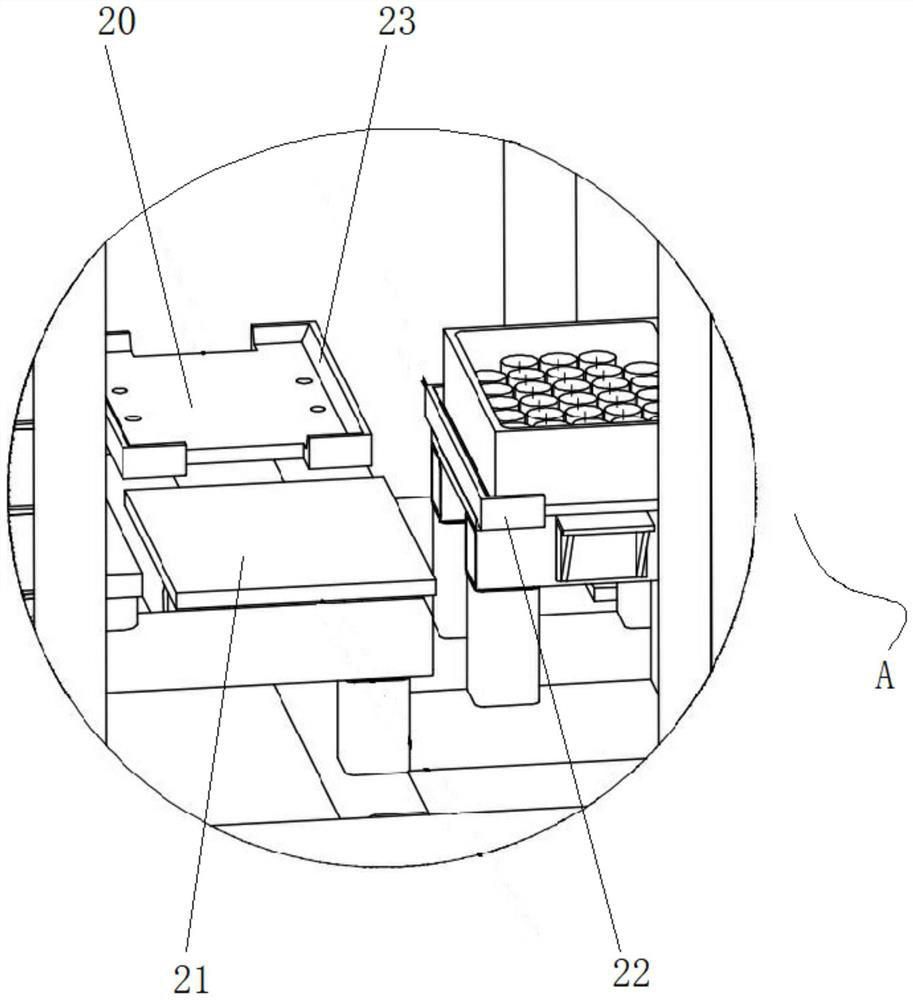

[0031] according to figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, the present embodiment proposes an automatic palletizer for the rare earth permanent magnet industry process, including a frame 1 and a driving part, and the driving part is located at the top of the frame 1, And the driving part includes a first guide rail 2 and a slide seat 3, the slide seat 3 is movably installed on the first guide rail 2, and the slide seat 3 is provided with a second guide rail 4, and a slide seat 4 is movably installed on the second guide rail 4 Block 5, one side of the slider 5 is provided with a mounting plate 6, and the mounting plate 6 is provided with a third guide rail 7, a slide plate 8 is movably installed on the third guide rail 7, and the bottom of the slide plate 8 is provided with a sleeve Pipe 9, a mounting frame 10 is provided below the sleeve 9, a spring rod 11 is movable inside the sleeve 9, and a rubber pad 12 is provided at the lower end of the spring rod 11;

[0032]Both end...

Embodiment 2

[0038] according to figure 1 , 2 , 4, 5, 6, and 7, the present embodiment proposes a rare earth permanent magnet industry process automatic palletizer, including a frame 1 and a driving part, the driving part is located on the top of the frame 1, and the driving part includes a first Guide rail 2 and slide seat 3, described slide seat 3 is movably installed on the first guide rail 2, and second guide rail 4 is provided on the slide seat 3, slide block 5 is movably installed on the described second guide rail 4, and described slide One side of the block 5 is provided with a mounting plate 6, and the mounting plate 6 is provided with a third guide rail 7, a slide plate 8 is movably installed on the third guide rail 7, and a sleeve 9 is provided at the bottom of the slide plate 8, and the sleeve 9 A mounting frame 10 is provided below the tube 9, a spring rod 11 is movable inside the casing 9, and a rubber pad 12 is provided at the lower end of the spring rod 11;

[0039] Both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com