Kerb mounting trolley

A technology of curbs and trolleys, applied in roads, roads, road repairs, etc., can solve the problems of uneven ground, difficult adjustment and installation of curbs, heavy curb weight, etc., and achieve the effect of good control of the rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

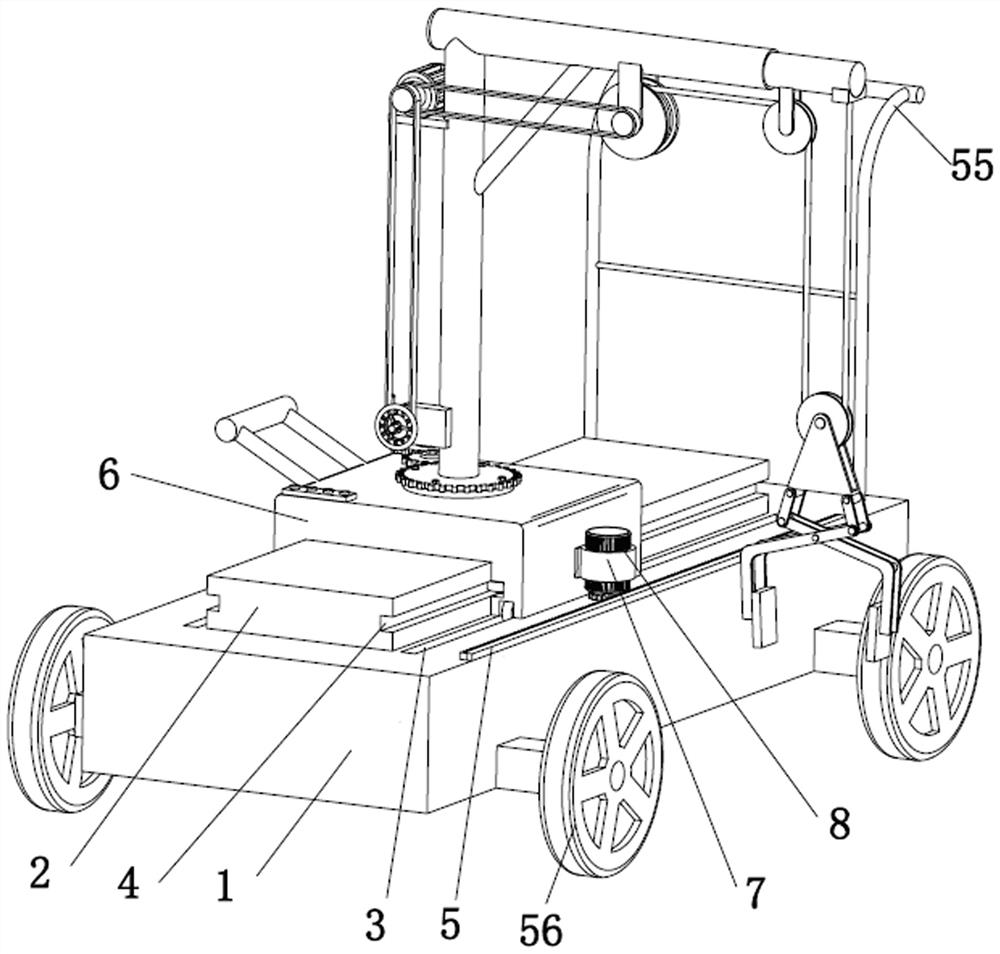

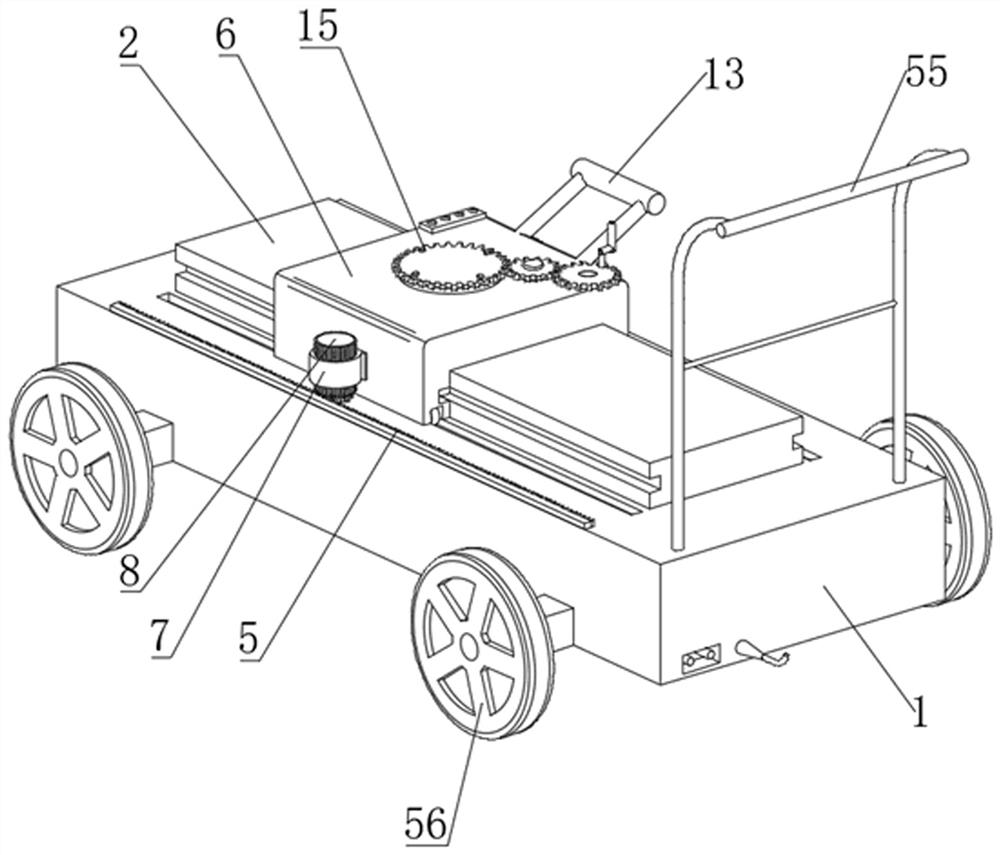

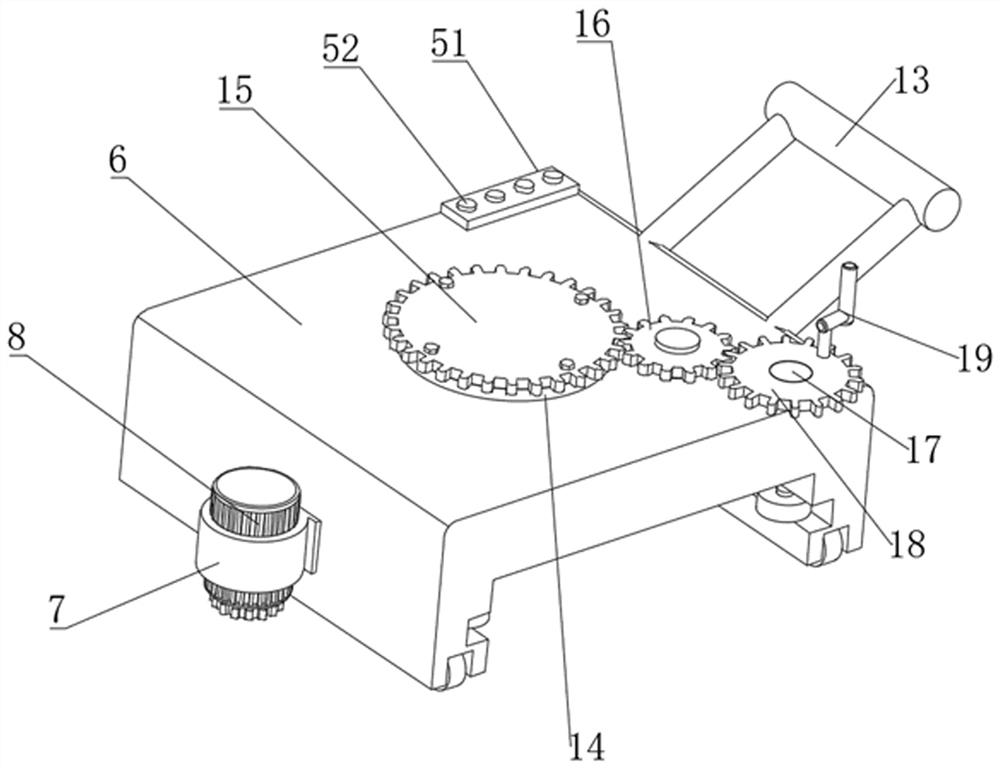

[0044] A trolley for installing curbstones, including a car body 1, wheels 56 are installed on the bottom of the car body 1, a slide rail 2 is arranged on the top of the car body 1, and the top of the car body 1 is along the direction of the slide rail 2 A rack 5 is fixedly arranged, and a moving block 6 is slidably installed on the slide rail 2, and a moving motor 8 is installed on one side of the moving block 6 along the direction of the slide rail 2 through a fixed sleeve 7. The moving A first gear 10 is installed on the rotating shaft 9 of the motor 8, and the first gear 10 meshes with the rack 5; the top of the moving block 6 is rotatably equipped with a first rotating disc 14, and the first rotating disc 14 is fixedly equipped with a second gear 15, the top of the moving block 6 is rotated to install the third gear 16, the third gear 16 meshes with the second gear 15, the top of the moving block 6 is fixedly installed with a fixed rod 17, and the fixed rod 17 is rotatably...

Embodiment 2

[0048]A trolley for installing curbstones, including a car body 1, wheels 56 are installed on the bottom of the car body 1, a slide rail 2 is arranged on the top of the car body 1, and the top of the car body 1 is along the direction of the slide rail 2 A rack 5 is fixedly arranged, and a moving block 6 is slidably installed on the slide rail 2, and a moving motor 8 is installed on one side of the moving block 6 along the direction of the slide rail 2 through a fixed sleeve 7. The moving A first gear 10 is installed on the rotating shaft 9 of the motor 8, and the first gear 10 meshes with the rack 5; the top of the moving block 6 is rotatably equipped with a first rotating disc 14, and the first rotating disc 14 is fixedly equipped with a second gear 15. The top of the moving block 6 is rotated to install the third gear 16, the third gear 16 meshes with the second gear 15, the top of the moving block 6 is fixedly installed with a fixed rod 17, and the fixed rod 17 is rotated an...

Embodiment 3

[0056] A trolley for installing curbstones, including a car body 1, wheels 56 are installed on the bottom of the car body 1, a slide rail 2 is arranged on the top of the car body 1, and the top of the car body 1 is along the direction of the slide rail 2 A rack 5 is fixedly arranged, and a moving block 6 is slidably installed on the slide rail 2, and a moving motor 8 is installed on one side of the moving block 6 along the direction of the slide rail 2 through a fixed sleeve 7. The moving A first gear 10 is installed on the rotating shaft 9 of the motor 8, and the first gear 10 meshes with the rack 5; the top of the moving block 6 is rotatably equipped with a first rotating disc 14, and the first rotating disc 14 is fixedly equipped with a second gear 15. The top of the moving block 6 is rotated to install the third gear 16, the third gear 16 meshes with the second gear 15, the top of the moving block 6 is fixedly installed with a fixed rod 17, and the fixed rod 17 is rotated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com