A kind of low-viscosity thermosetting particleboard starch adhesive and preparation method thereof

A starch adhesive, particle board technology, applied in the directions of adhesives, adhesive types, graft polymer adhesives, etc., can solve problems such as viscosity increase, achieve a low degree of self-crosslinking, widen application fields, and fluidity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

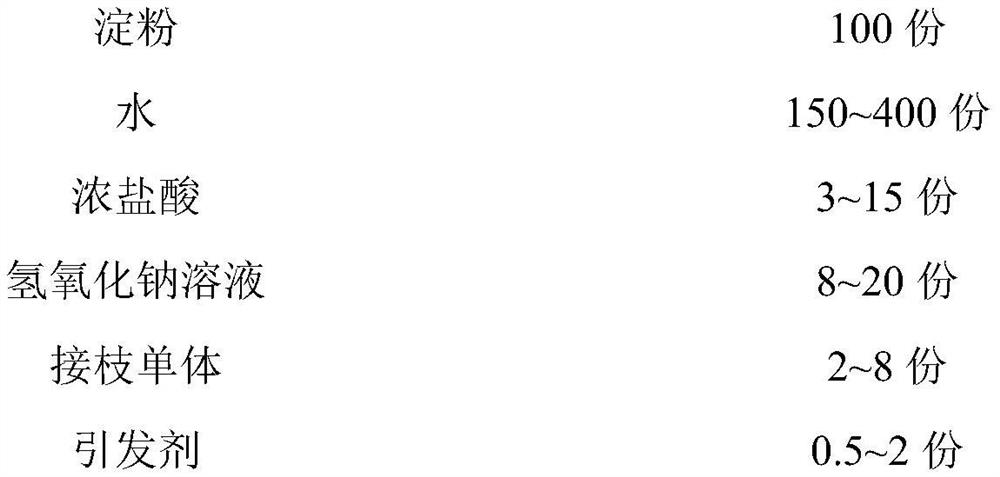

Method used

Image

Examples

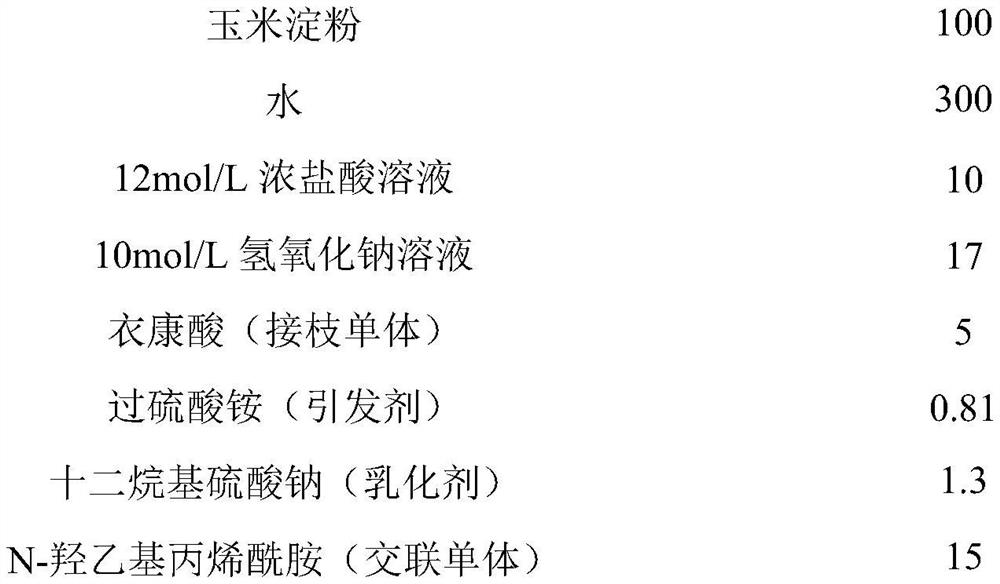

Embodiment 1

[0047] Formula (mass / g):

[0048]

[0049] Process flow:

[0050] (1) starch and water are made into starch milk with a concentration of 35% in mass ratio on a dry basis of starch, and stir evenly;

[0051] (2) Adjust the temperature of starch milk to 60°C at a rate of 2°C / min, dilute 10g of 12mol / L concentrated hydrochloric acid solution to 0.6mol / L, add to starch milk for acidolysis, acidolysis for 2h, and then add 10mol / L L sodium hydroxide solution to adjust the pH to 4; adjust the temperature of the acid-hydrolyzed starch milk to 85°C at a rate of 1°C / min, and keep the reaction temperature unchanged at 85°C after pre-gelatinization for 30 minutes;

[0052] (3) Dissolve 0.61g initiator in 35g water to make an initiator solution, dissolve 1.3g emulsifier in 24.8g water to make a 5% emulsifier solution, take 5g graft monomer itaconic acid and dissolve it in 45g water To prepare a solution, take 15g of cross-linking monomer N-hydroxyethyl acrylamide and dissolve it in th...

Embodiment 2

[0059] Formula (mass / g):

[0060]

[0061] Process flow:

[0062] (1) starch and water are made into starch milk with a concentration of 35% in mass ratio on a dry basis of starch, and stir evenly;

[0063] (2) adjust the temperature of starch milk to 60°C at a rate of 2°C / min, keep the temperature for 2h, then add 10mol / L concentrated hydrochloric acid solution to adjust pH to 4; adjust the temperature of starch milk to 85°C at a rate of 1°C / min , after pregelatinization for 30min, the reaction temperature remained unchanged at 85℃;

[0064] (3) Dissolve 0.61g of initiator in 35g of water to prepare an initiator solution, dissolve 1.3g of emulsifier in 24.8g of water to prepare a 5% emulsifier solution, and dissolve 5g of graft monomer itaconic acid in 45g of water to prepare into a solution, take 15g of cross-linking monomer N-hydroxyethyl acrylamide and dissolve it in the graft monomer solution;

[0065] (4) The initiator and emulsifier solution prepared in step (3) a...

Embodiment 3

[0072] Formula (mass / g):

[0073]

[0074] Process flow:

[0075] (1) starch and water are made into starch milk with a concentration of 35% in mass ratio on a dry basis of starch, and stir evenly;

[0076] (2) Adjust the temperature of starch milk to 60°C at a rate of 2°C / min, dilute 10g of 12mol / L concentrated hydrochloric acid solution to 0.6mol / L, add to starch milk for acidolysis, acidolysis for 2h, and then add 10mol / L L sodium hydroxide solution to adjust the pH to 4; adjust the temperature of the acid-hydrolyzed starch milk to 85°C at a rate of 1°C / min, and keep the reaction temperature unchanged at 85°C after pre-gelatinization for 30 minutes;

[0077] (3) Dissolve 0.61g initiator in 35g water to make an initiator solution, dissolve 1.3g emulsifier in 24.8g water to make a 5% emulsifier solution, take 5g graft monomer itaconic acid and dissolve it in 45g water To prepare a solution, take 15g of cross-linking monomer N-methylol acrylamide and dissolve it in the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com