Al-Si-Cu high-thermal-conductivity die-casting aluminum alloy and preparation method thereof

A technology of al-si-cu and cast aluminum alloy, which is applied in the field of aluminum alloy materials, can solve the problems such as the decline of thermal conductivity, and achieve the effects of improving strength, avoiding deformation, and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

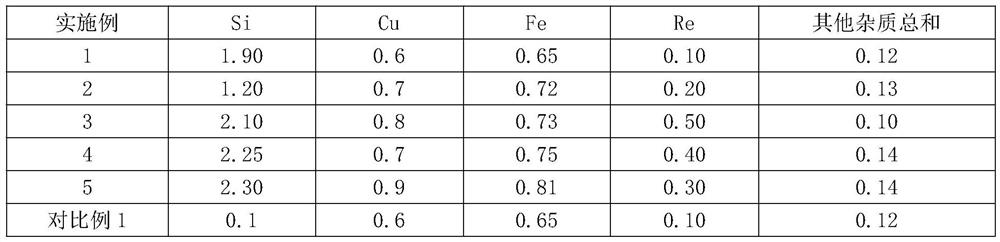

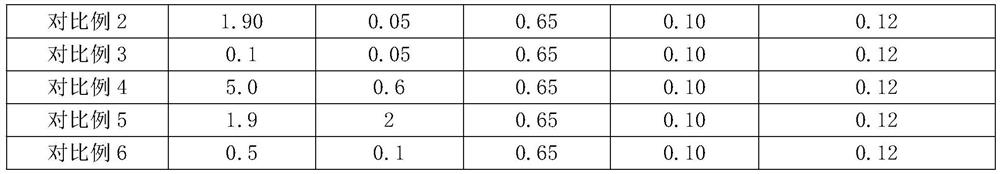

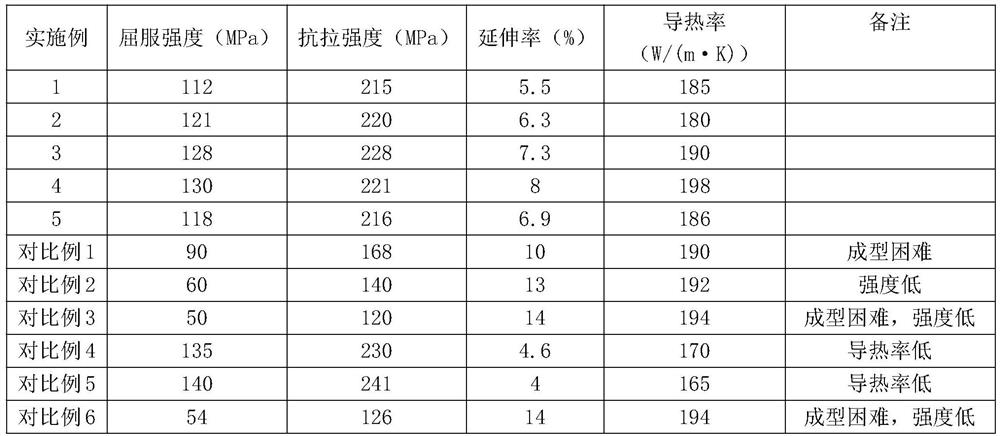

Examples

Embodiment 1

[0025] Taking Embodiment 1 as an example, it specifically includes the following steps:

[0026] (1) Raw material preparation: Al ingot, Al-Sr alloy, Al-RE alloy, Al-Cu alloy, elemental 3303Si, and pure Fe powder are quantitatively prepared according to the mass percentage. Among them, Fe and Si can be added in the form of pure metal, and RE and Cu can be added in the form of master alloy.

[0027] (2) Melting: After melting the Al ingot, heat up to 750°C, add Fe powder and pure Si, melt the Al-Cu alloy, stir evenly, and obtain melt I; cool down to 700°C, add the Al- The RE alloy was melted to obtain Melt II; it was then left to stand for 30 minutes.

[0028] (3) Die-casting: the temperature of the melt II was lowered to 700° C., and the scum on the surface was removed, and cast into an ingot to obtain the low-silicon, low-iron, and high-fluidity high-thermal conductivity die-casting aluminum alloy. Wherein, based on the mass percentage of the melt II, the added amount of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com