Cold-rolled steel sheet for battery case with tensile strength of 320 MPa and production method of cold-rolled steel sheet

A technology of cold-rolled steel sheet and tensile strength, which is applied to cold-rolled steel sheet, cold-rolled steel sheet for battery shell with a tensile strength of 320 MPa and its production field, can solve the problem of poor performance uniformity of cold-rolled steel sheet, difficulty in meeting high-speed stamping shell-making, Cold-rolled steel plate production cost is low and other issues, to achieve the effect of good surface quality, high production efficiency and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

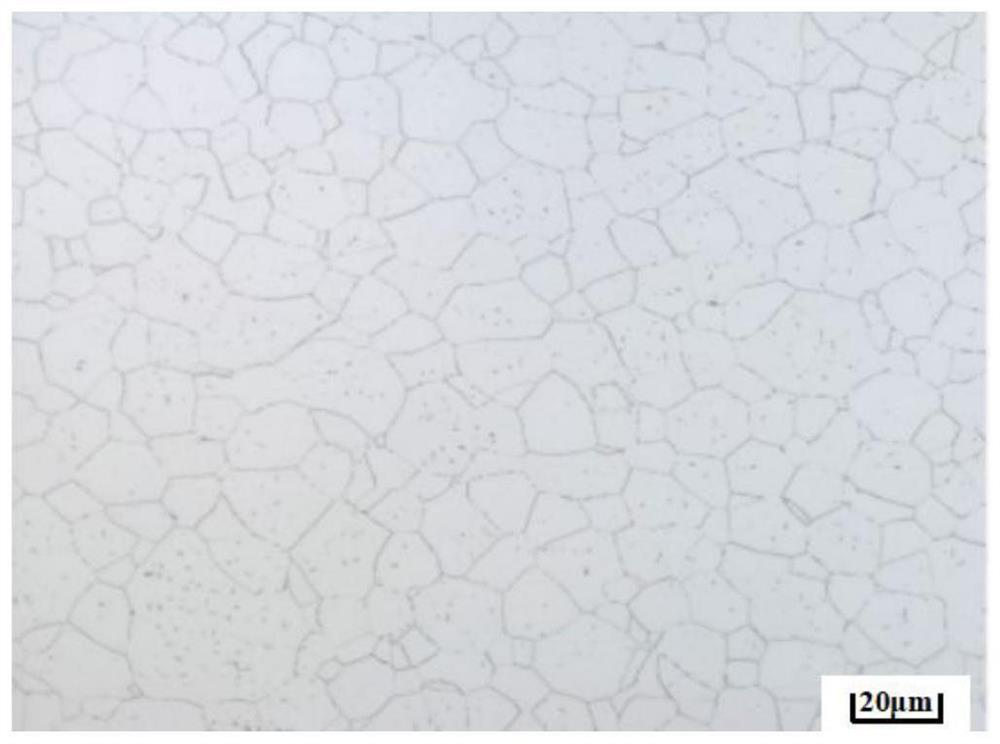

Image

Examples

Embodiment Construction

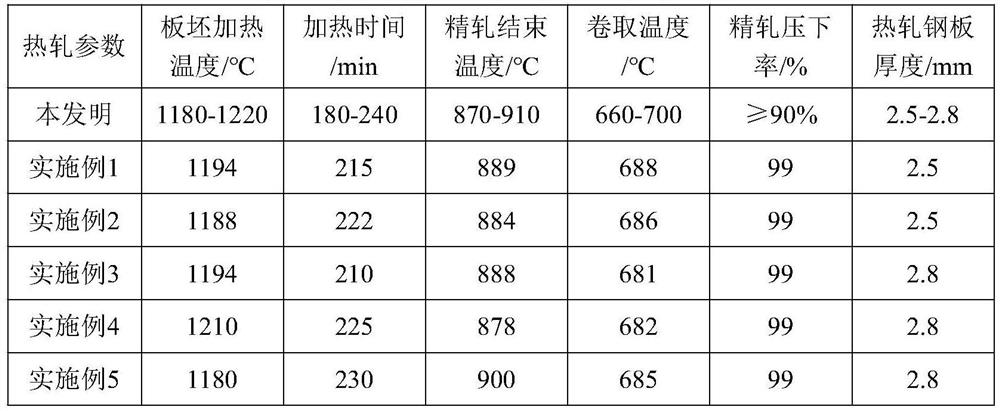

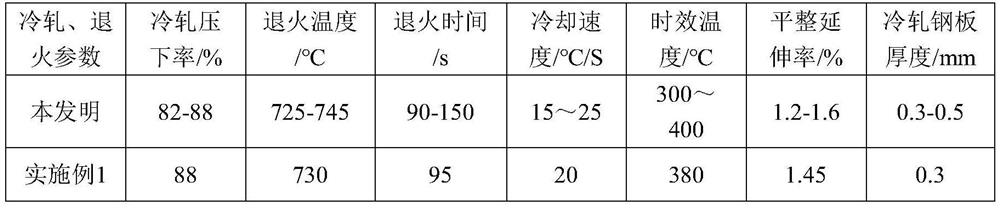

[0045] The present invention will be further described below in conjunction with specific examples 1-5, as shown in Table 1-4, Table 1 is the chemical composition (by weight percentage) of the steel of the embodiment of the present invention, and the balance is Fe and unavoidable impurities.

[0046] Table 1 Chemical composition of the steel of the embodiment of the present invention, unit: weight percent.

[0047] element C Si mn P S B this invention 0.015-0.025 ≤0.03 0.10-0.20 ≤0.015 ≤0.015 0.001-0.002 Example 1 0.021 0.004 0.12 0.013 0.008 0.0017 Example 2 0.018 0.001 0.15 0.011 0.008 0.0015 Example 3 0.025 0.008 0.20 0.010 0.008 0.0013 Example 4 0.023 0.003 0.19 0.014 0.007 0.0014 Example 5 0.019 0.003 0.16 0.012 0.005 0.0015

[0048] The continuous casting slab is rolled after being heated at 1180-1220°C for 180-240min, the hot rolling is a two-stage rolling process, the rough rolling i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com