Double deep groove ball bearing pre-tightening eccentric cam follower

A technology of deep groove ball bearings and eccentric cams, applied in the direction of cam followers, bearing elements, shafts and bearings, etc., can solve the problems of rod end damage, difficulty in obtaining twisting torque, interference, etc., and achieve shock load reduction and structural form Simple, excellent servo performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

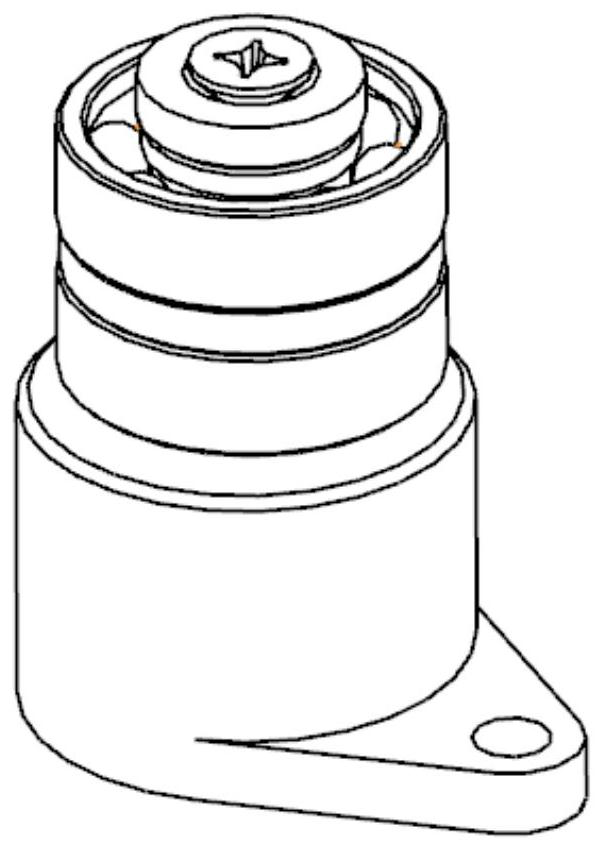

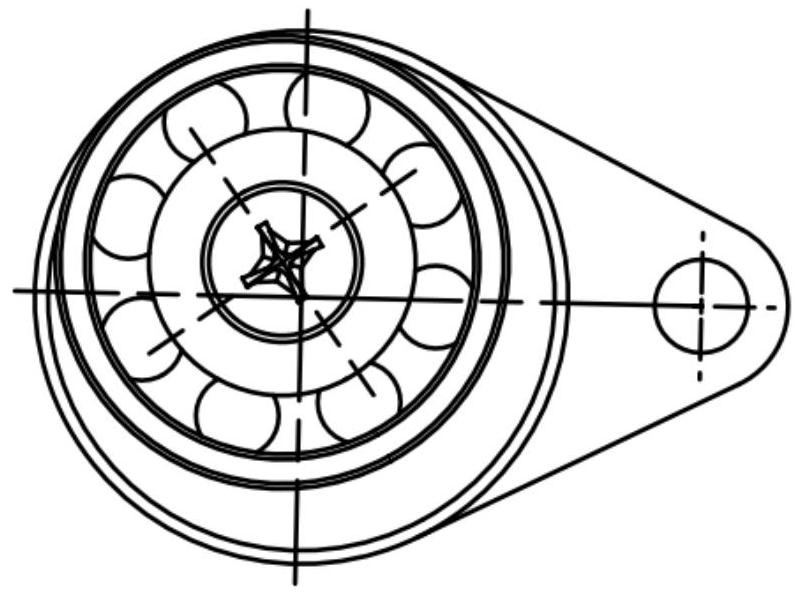

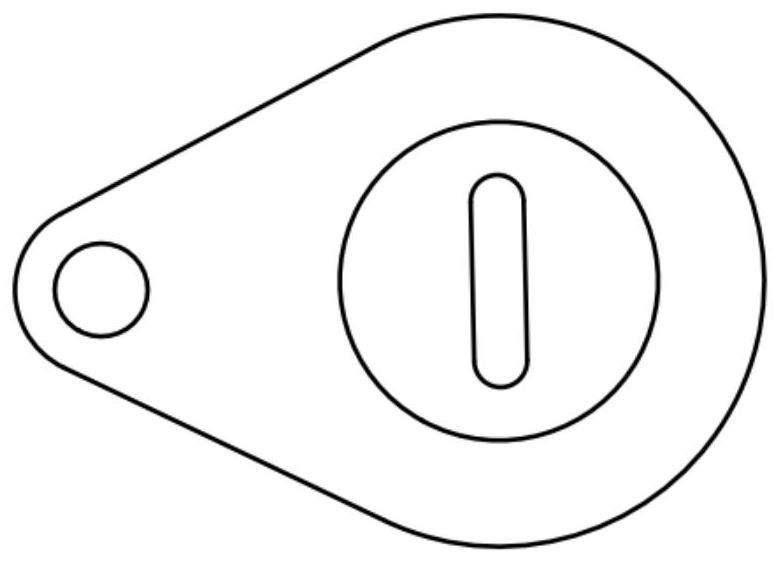

[0020] refer to Figure 1-Figure 5 . In the preferred embodiment described below, a double deep groove ball bearing preloaded eccentric cam follower includes: an eccentric wheel shaft 1 with a flange rocker arm base and a cantilever shaft, through which the cantilever shaft diameter of the eccentric wheel shaft 1 is installed. The adjustment ring 3 sandwiched between the upper deep groove ball bearing 4 and the lower deep groove ball bearing 2, wherein: the upper deep groove ball bearing 4 fixes the adjustment ring 3 in the bearing seat through the outer ring to form a closed structure, and the screw 6 Axially pass through the through hole of the preload cover 5 and the threaded hole of the cantilever shaft end, tighten the preload cover 5, and connect the double deep groove ball bearing between the end plane of the eccentric wheel shaft 1 and the preload cover 5.

[0021] There is an eccentric distance between the axis center of the eccentric wheel shaft 1 cylindrical base a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com