Refrigerant capable of reducing flammability

A technology of refrigerants and mixed refrigerants, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problem of large temperature changes of mixed refrigerants, the reduction of flammability of mixed refrigerants, and the vulnerability of mixed refrigerants to external temperatures The impact of the problem, to achieve the effect of reducing flammability, improving flexibility and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

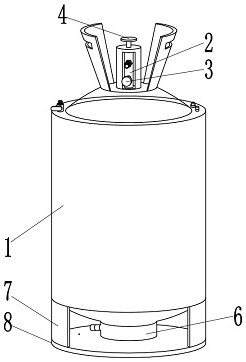

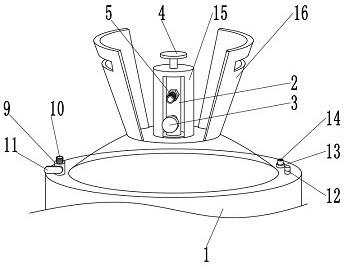

[0041] The present invention provides a refrigerant with reduced flammability characteristics through improvement, such as Figure 1-Figure 4 As shown, it consists of the following mass percentage components:

[0042] R134A refrigerant 30%;

[0043] R125 refrigerant 25%;

[0044] R600 refrigerant 24%;

[0045] R404A refrigerant 17%.

[0046] Further, the tank body 1 and the following steps are included:

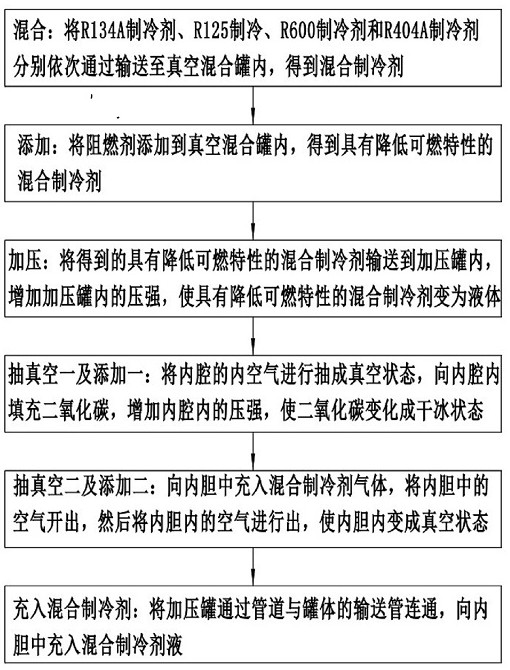

[0047] S1. Mixing: transport R134A refrigerant, R125 refrigerant, R600 refrigerant and R404A refrigerant to the vacuum mixing tank in turn to obtain mixed refrigerant;

[0048] S2. Addition: no flame retardant is added;

[0049] S3. Pressurization: transport the obtained mixed refrigerant into a pressurized tank, increase the pressure in the pressurized tank, and make the mixed refrigerant into a liquid;

[0050] S4. Vacuumizing one and adding one: evacuate the inner cavity 20 into a vacuum state, fill the inner cavity 20 with carbon dioxide, increase the pressure in th...

Embodiment 2

[0058] A refrigerant with reduced flammability properties consisting of the following components in mass percent:

[0059] R134A refrigerant 30%;

[0060] R125 refrigerant 25%;

[0061] R600 refrigerant 24%;

[0062] R404A refrigerant 17%;

[0063] Brominated flame retardants: 4%.

[0064] Further, the tank body 1 and the following steps are included:

[0065] S1. Mixing: transport R134A refrigerant, R125 refrigerant, R600 refrigerant and R404A refrigerant to the vacuum mixing tank in turn to obtain mixed refrigerant;

[0066] S2. Addition: adding a flame retardant to the vacuum mixing tank, the brominated flame retardant is brominated polystyrene, and the temperature in the mixing tank is set at 22°C to obtain a mixed refrigerant with reduced flammability;

[0067] S3. Pressurization: The obtained mixed refrigerant with reduced flammability is transported into the pressurized tank, and the pressure in the pressurized tank is increased. The pressure in the pressurized tan...

Embodiment 3

[0072] A refrigerant with reduced flammability properties, a refrigerant with reduced flammability properties, consisting of the following components in mass percent:

[0073] R134A refrigerant 28%;

[0074] R125 refrigerant 25%;

[0075] R600 refrigerant 24%;

[0076] R404A refrigerant 17%;

[0077] Brominated flame retardants: 6%.

[0078] Further, the tank body 1 and the following steps are included:

[0079] S1. Mixing: transport R134A refrigerant, R125 refrigerant, R600 refrigerant and R404A refrigerant to the vacuum mixing tank in turn to obtain mixed refrigerant;

[0080] S2. Addition: adding a flame retardant to the vacuum mixing tank, the brominated flame retardant is brominated polystyrene, and the temperature in the mixing tank is set at 22°C to obtain a mixed refrigerant with reduced flammability;

[0081] S3. Pressurization: The obtained mixed refrigerant with reduced flammability is transported into the pressurized tank, and the pressure in the pressurized t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com