Method and system for constructing and predicting service life prediction model of key component of wheel set

A life prediction model and technology of life prediction, applied in the field of prediction, can solve the problems of model prediction effect discount, difficult to realize, model cannot be established mechanism research, etc., to achieve the effect of reducing subjectivity and objective calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this embodiment, the life prediction of the wheel set is used as an example for illustration, but it does not mean that the solution provided by the present invention is only applicable to the life prediction of the wheel set. It can also be applied to life prediction of other objects according to different prediction objects.

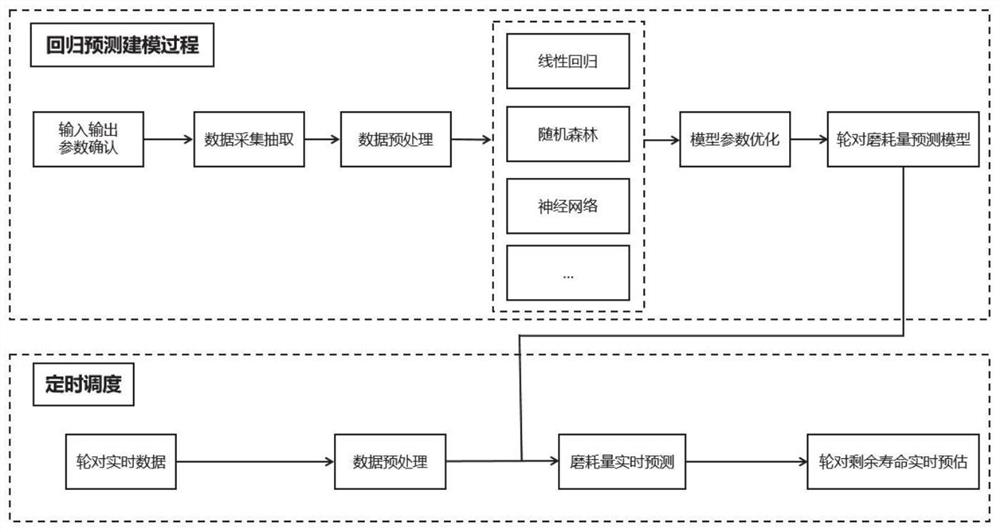

[0057] In this embodiment, a method for constructing a life prediction model for key components of a wheel set is disclosed, including:

[0058] Step 1: Analyze the business scenario and determine the input and output parameters of the model.

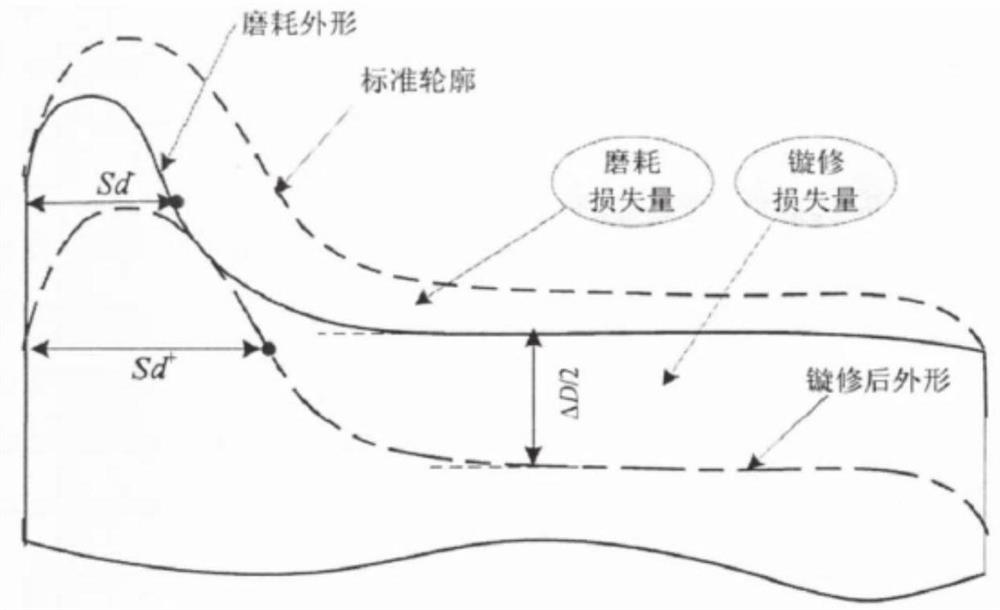

[0059] The remaining wear of the wheel diameter is related to the inner diameter of the wheel and the remaining wheel diameter of the wheel, and the inner diameter of the wheel is a fixed value, that is, it is necessary to find out the correlation with the remaining wheel diameter of the wheel. As the wheels wear with increasing mileage, driving speed and ambient temperature, etc., a prediction model ...

Embodiment 2

[0075] Based on the above method of Embodiment 1, a prediction model is obtained, and based on the output result of the model, that is, the real-time residual wear of the wheel diameter, the life prediction of the key components of the wheel set is performed, see the appendix Figure 4 , 5 As shown, the life prediction process includes:

[0076] (1) Solution of wheel diameter wear rate per 10,000 kilometers:

[0077] Wheel diameter wear rate per 10,000 kilometers in the latest turning repair = (wheel diameter value after the last turning turning - wheel diameter value before the latest turning turning) / running mileage in the latest turning repair cycle (10,000 kilometers).

[0078] The above wheel diameter values refer to the same wheel set (left wheel diameter value + right wheel wheel diameter value) / 2.

[0079] Further, the wear rate of all turning times of the wheel is obtained, and the maximum value and the minimum value of the wheel diameter wear rate of all turnin...

Embodiment 3

[0090] With the vigorous development of big data and artificial intelligence technology, from the perspective of data, a large amount of historical data is analyzed and mined to find the laws and hidden mechanism characteristics hidden behind the data, and provide strong support for the safety and economic operation monitoring of rail transit EMUs , to provide a new solution for the PHM intelligent operation and maintenance system to provide early warning of faults and assessment of remaining life.

[0091] This implementation example discloses a life prediction system for key components of a wheel set, including:

[0092] The prediction model obtaining module is configured to: obtain the optimal prediction model of the wheel set based on the above method;

[0093] The real-time estimation module of the remaining life is configured to: obtain the driving speed, ambient temperature and mileage of the wheel set in real time and perform preprocessing, select the corresponding pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com