Cambered surface shell of button type lithium secondary battery

A secondary battery and button-type lithium technology, applied in secondary batteries, battery components, circuits, etc., can solve electrical and safety risks and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

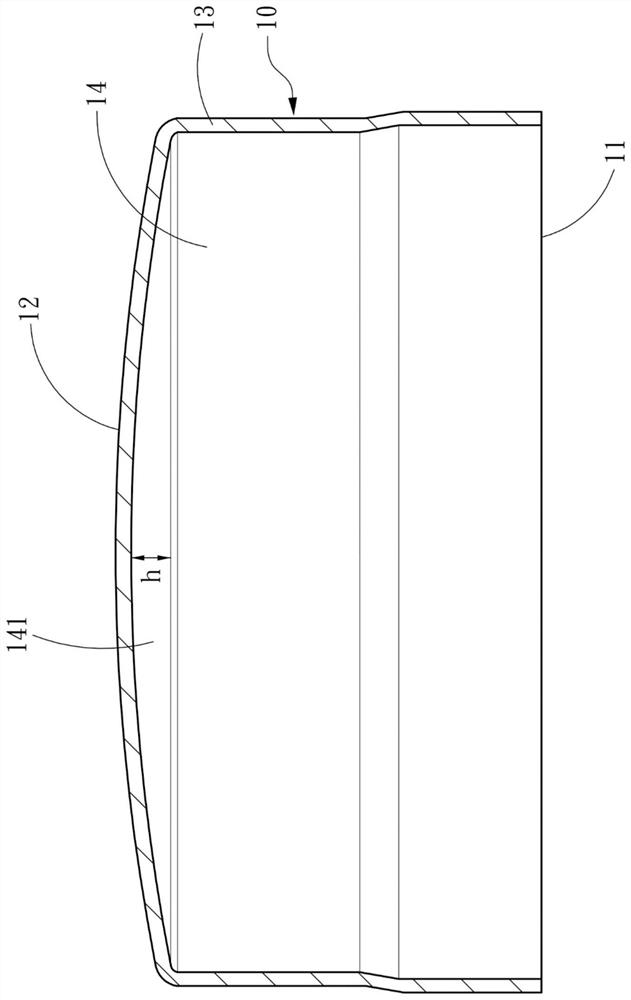

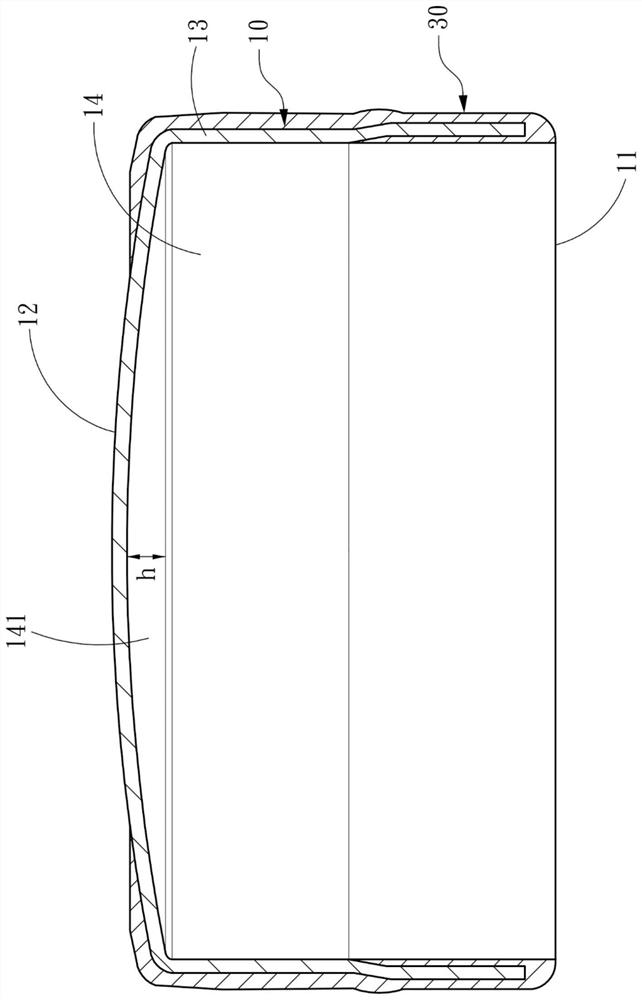

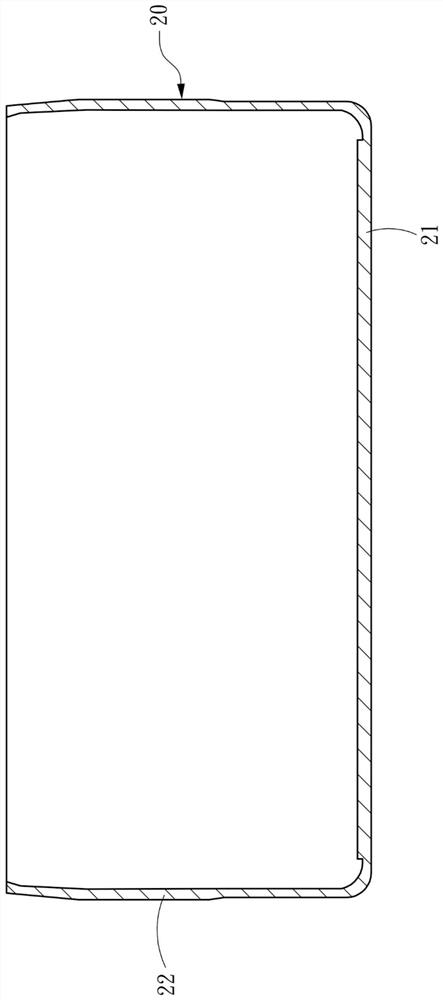

[0033] Relevant detailed description and technical contents of the present invention are as follows with regard to coordinating accompanying drawings now:

[0034] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the structure of the present invention provides a button-type lithium secondary battery composite casing structure, which includes an upper casing 10 and a lower casing 20. The upper casing 10 has a single-side opening 11 and an outer convex arc surface 12. 1. A ring wall 13 and an accommodating space 14, the outer convex arc surface 12 is far away from the one-sided opening 11, and the center height h of the outer convex arc surface 12 is 0.1 to 1 millimeter (mm), and the ring wall 13 surrounds Connecting the convex arc surface 12, the accommodating space 14 is located between the ring wall 13, the one-side opening 11 and the convex arc surface 12, and the outer surface of the ring wall 13 is covered with an insulating rubber ring 30, And the manufactu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com