Transparent heating film

A heating film, transparent technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of influence, glass breakage, uneven distribution of heating effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention are described in the appended drawings, wherein, in order to provide a clearer description and easier understanding of the technical features of the present invention, each part in the drawings is not drawn according to its relative size, and some dimensions are related to others Relevant scales have been exaggerated; irrelevant details have not been fully drawn in order to simplify the diagram.

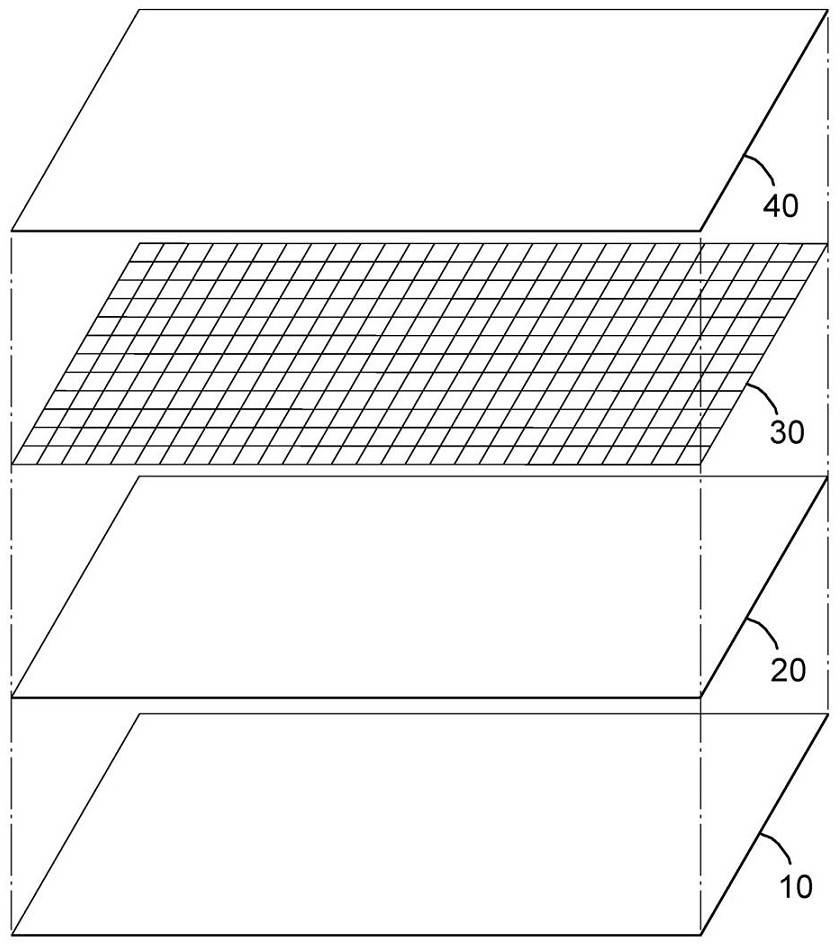

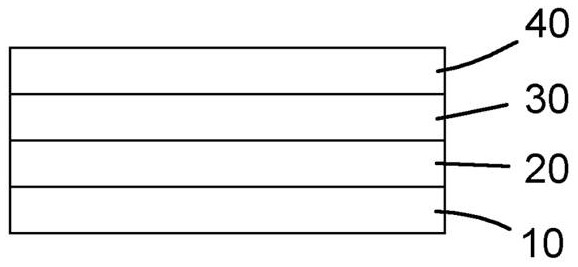

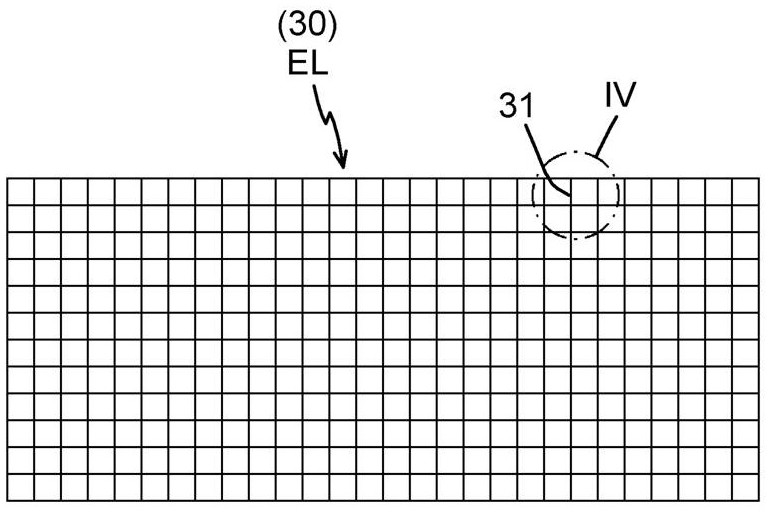

[0040] Figure 1 to Figure 4The first embodiment of the transparent heat-generating film of the present invention is described. This embodiment provides a transparent heat-generating film that can uniformly heat up the entire area and has rapid defogging performance. It includes a base layer 10, a resistance layer 20, An electrode layer 30 and a protective layer 40; in this embodiment, the base layer 10 is a thin glass plate with dielectric properties and high light transmittance, or flexible polyethylene terephthalate (PET )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap